Intelligent high-performance automatic oil purification apparatus

An oil purification and high-efficiency technology, applied in the direction of lubricating compositions, etc., can solve the problems that the filter cannot meet the use accuracy, the water storage tank cannot be automatically drained, and it is difficult to meet the purification requirements, so as to achieve good vacuum atomization effect and improve labor efficiency. Improvement of productivity and dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

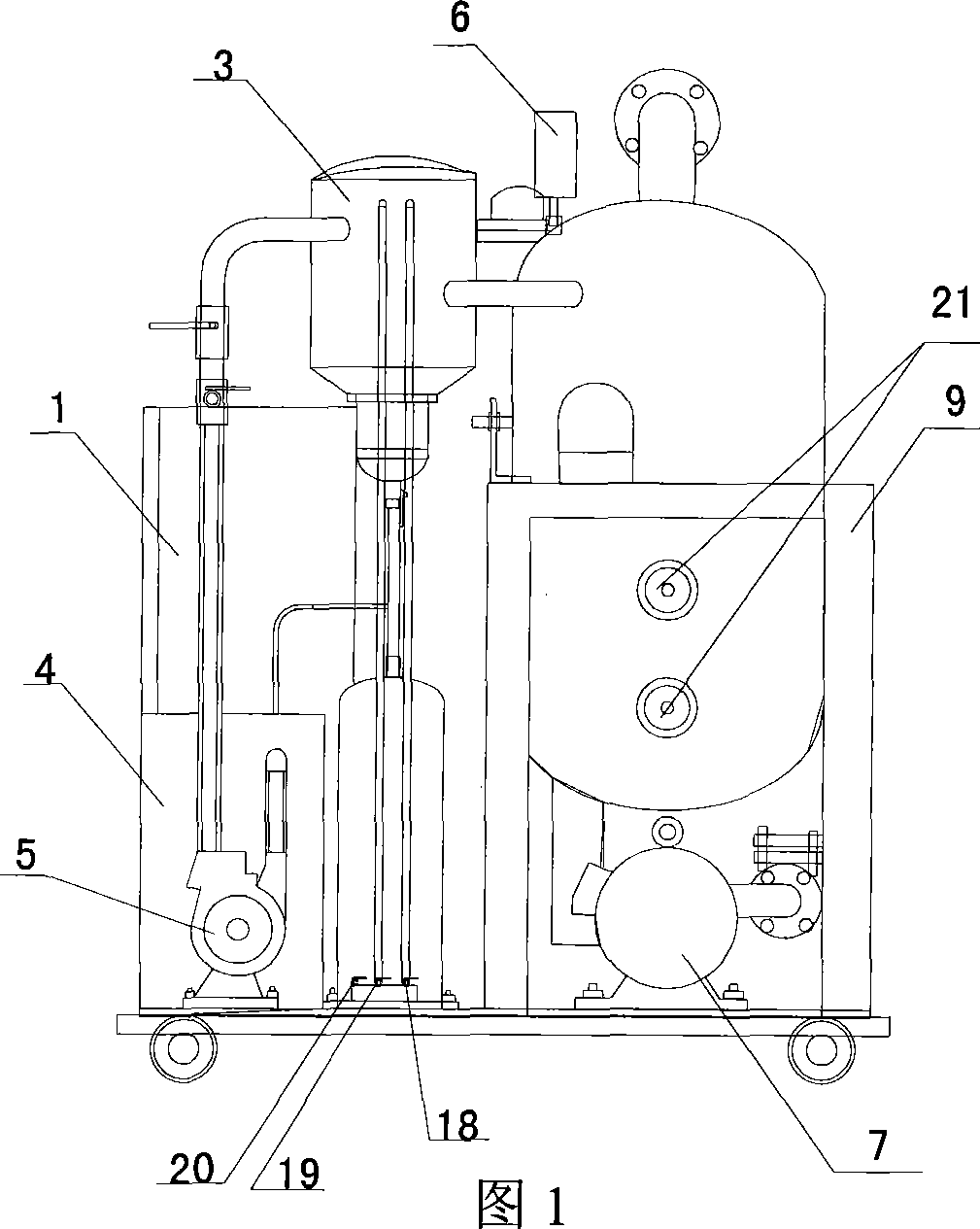

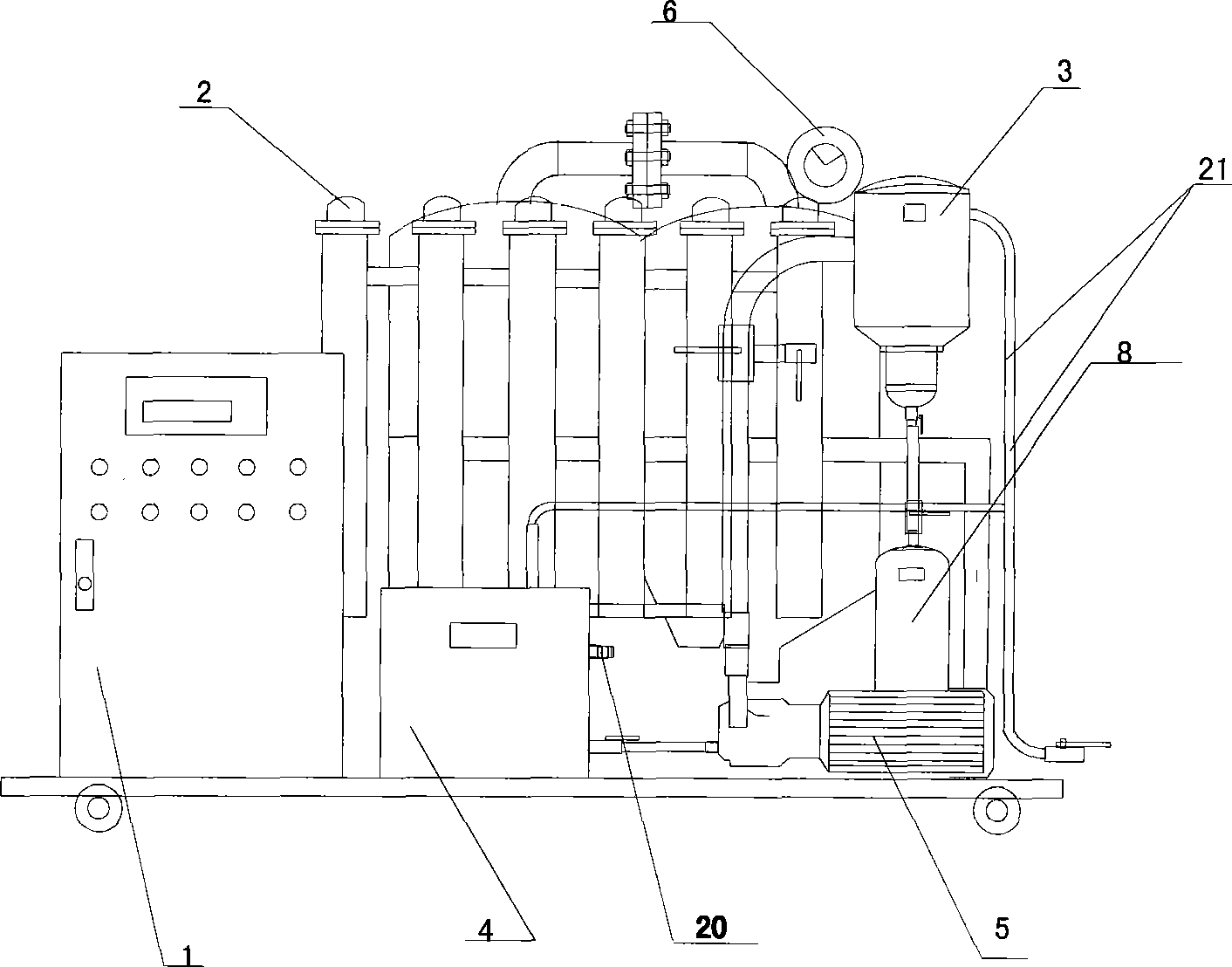

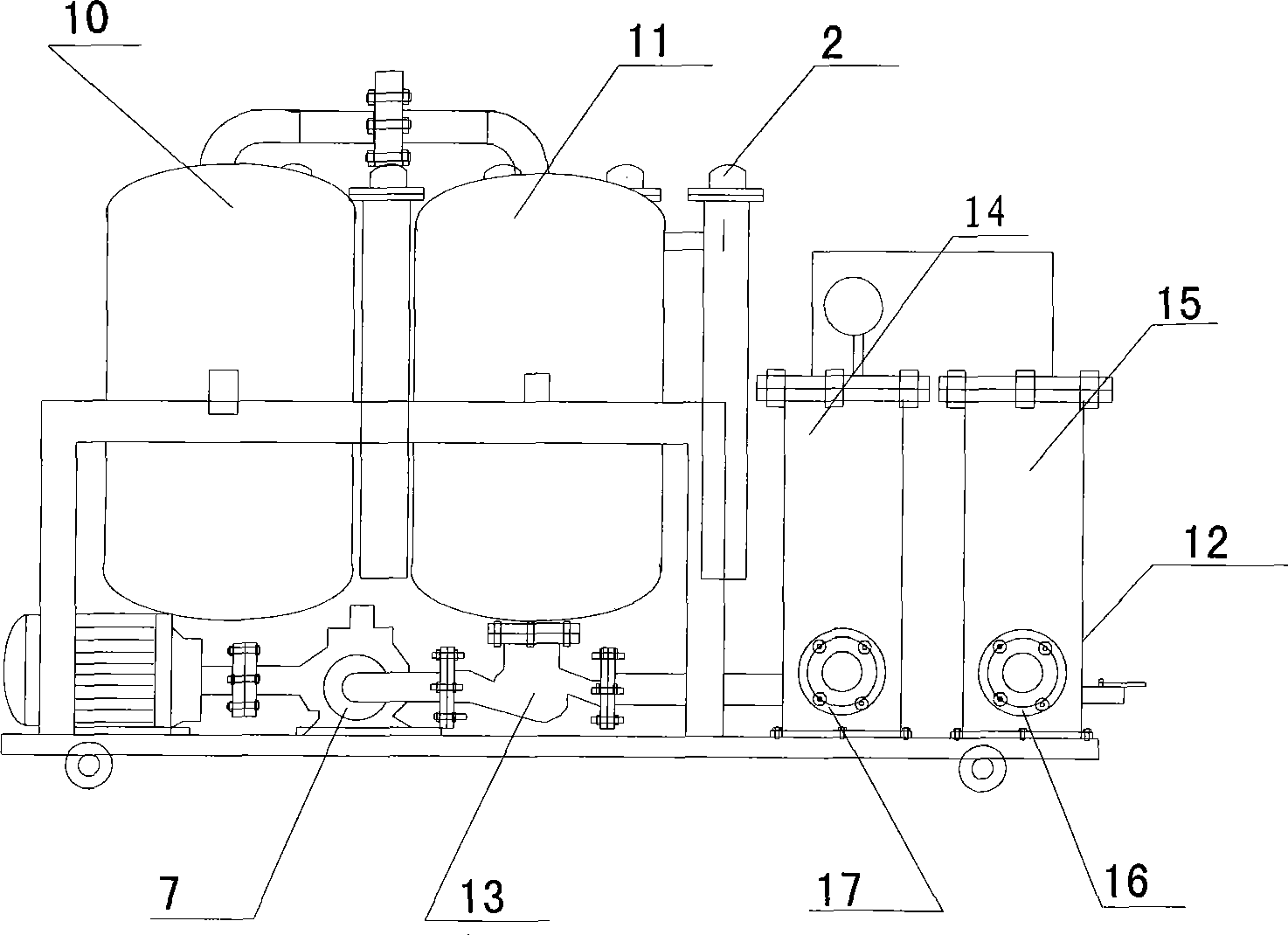

[0008] 1. Innovatively design and improve the spraying device of the vacuum atomization chamber to improve the atomization effect, increase the evaporation area of oil, and create a clean oil environment that is conducive to oil-water separation. Utilizing the technical principle that the medium circulation can reduce the size of the particles through rotation and stirring, the internal structure of the spraying device is scientifically designed. Using the polarity and aggregation of the stainless steel mesh, a rotating impeller is installed in the spraying device. On the premise of a large vacuum atomization chamber volume, the atomization area is greatly increased, so that the atomization efficiency is greatly improved, and an environment for improving the atomization state is formed inside, so that the atomization has achieved an unprecedented effect.

[0009] 2. According to the size of the condenser space, maximize the use of the function of the condenser and increase th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com