Metallic phase automatic detection method for stainless steel casting blank foreign matter

An automatic detection and inclusion technology, applied in measuring devices, optical testing flaws/defects, instruments, etc., can solve problems such as large errors, lack of identification of inclusions in slabs, etc., achieving high speed, simple and practical methods, and relative errors. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

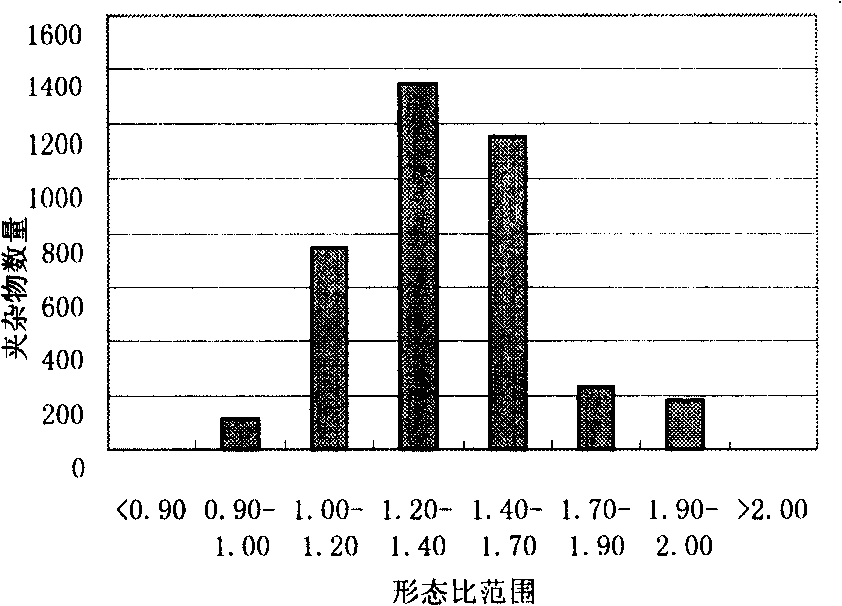

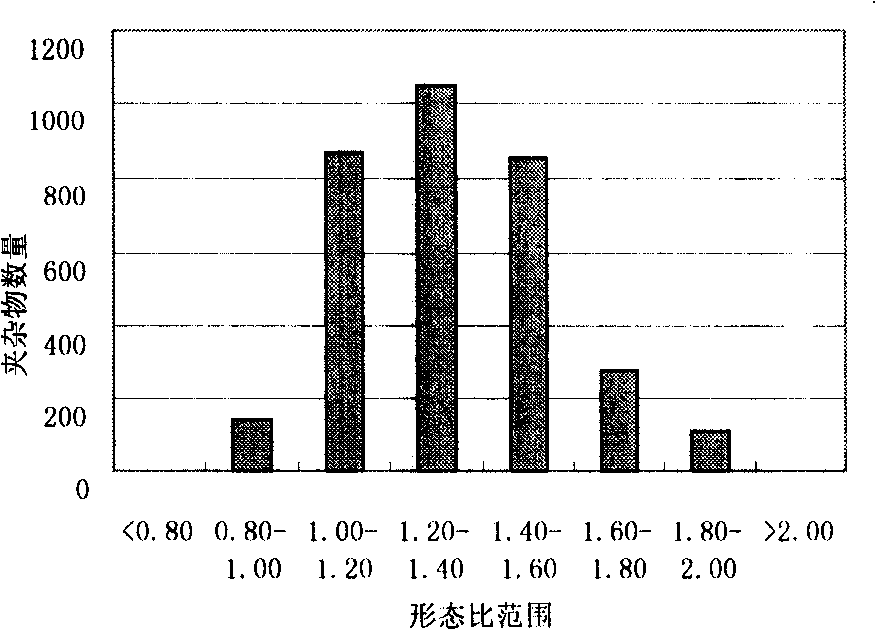

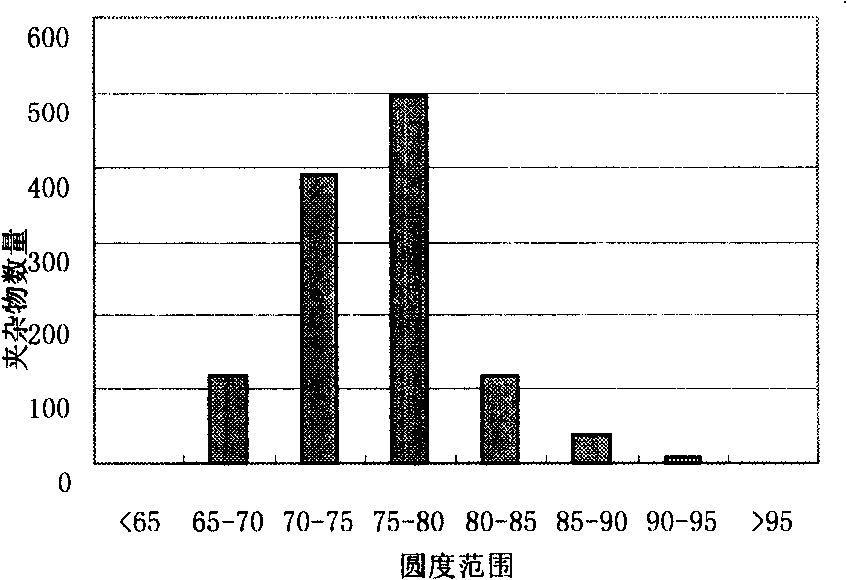

[0025] In this project, one steel type is analyzed in each of the four major types of stainless steel, austenitic, ferritic, martensite, and austenitic-ferritic. These four steel types are: 0Cr18Ni9(304), 0Cr13Al (405), 3Cr13 (420), 00Cr22Ni5Mo3N (2205). The desulfurization products of these steel grades are relatively simple, mainly manganese sulfide, and sulfide is occasionally found in the oxide. In the deoxidation stage, silicon, aluminum, calcium and mixed elements are used for deoxidation, and there are many types of oxides, which can be mainly divided into six types, which are: calcium silicate, aluminum silicate, calcium aluminate, oxide Aluminum, silica, composite inclusions. Due to the adoption of various processes for deoxidation, these inclusions basically represent the oxide inclusions of various stainless steels. Experimental research shows that several types of oxide inclusions are difficult to distinguish in terms of gray value, roundness, smoothness, and asp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com