Electroluminescent device

An electroluminescence device and a luminescence technology, applied in the field of manufacturing conversion elements, can solve problems such as low luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

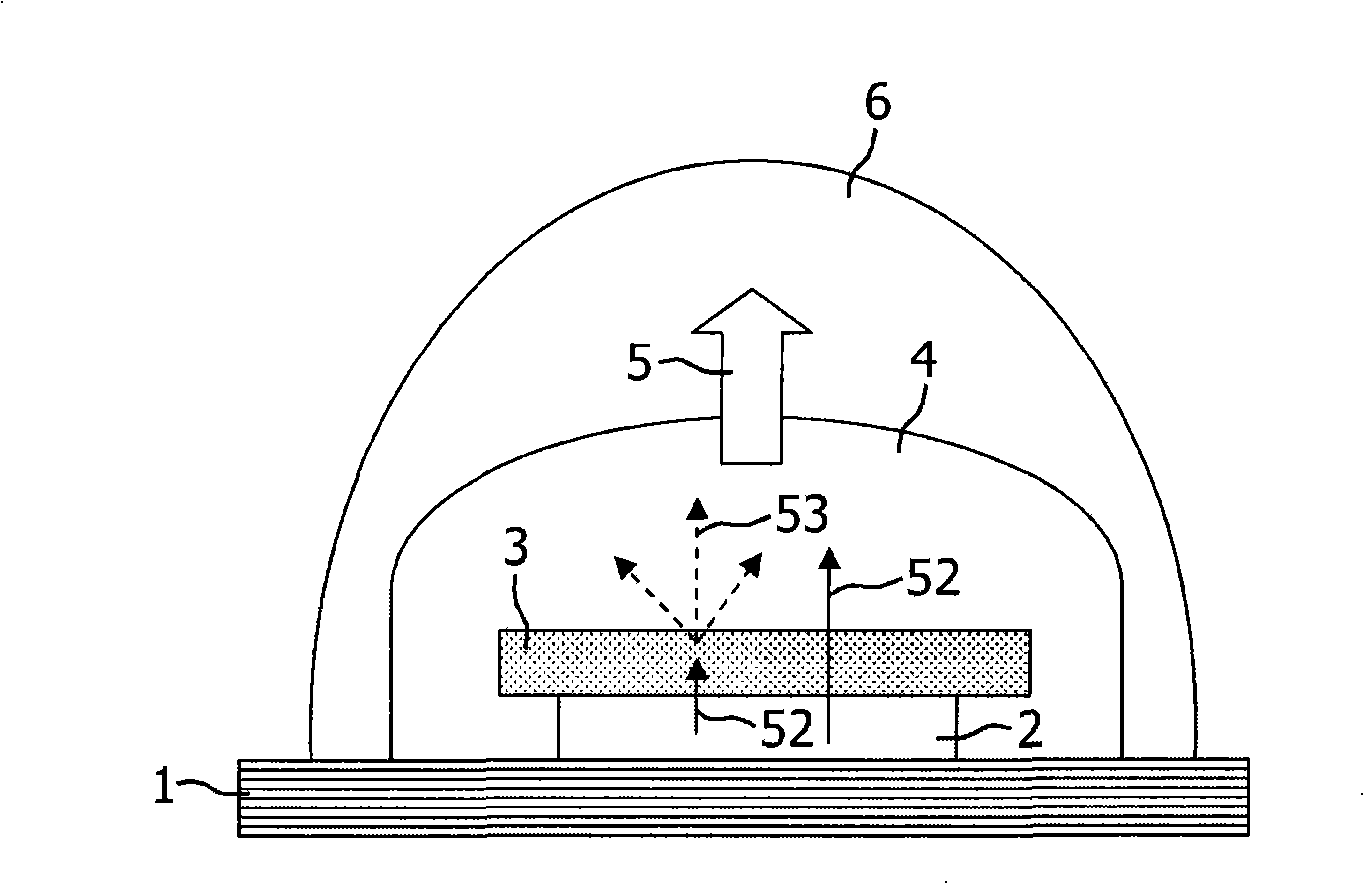

[0042] figure 2 An embodiment of a luminescent device according to the invention is schematically shown with a substrate 1 and an electroluminescent light source 2 applied on the substrate 1 for emitting primary radiation 52 and arranged on the electroluminescent light source 2 The conversion element 3 on the top is used for at least partially absorbing the primary radiation 52 and emitting the secondary radiation 53 . The electroluminescent light source 2 comprises an electroluminescent layer structure applied on the substrate 1, which structure has at least one organic or inorganic electroluminescent layer, which layer is arranged between two electrodes. Here, primary radiation is emitted by a transparent electrode (top emitter) on the side facing away from the substrate, and is reflected by the electrode facing the substrate 1 and / or the substrate 1 (eg aluminium). Here, the luminous means can also comprise a planar arrangement of several electroluminescent light sources,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com