Multifunctional household reverse osmosis water purifier

A reverse osmosis, multi-functional technology, applied in osmosis/dialysis water/sewage treatment, non-polluted water treatment, adsorption water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

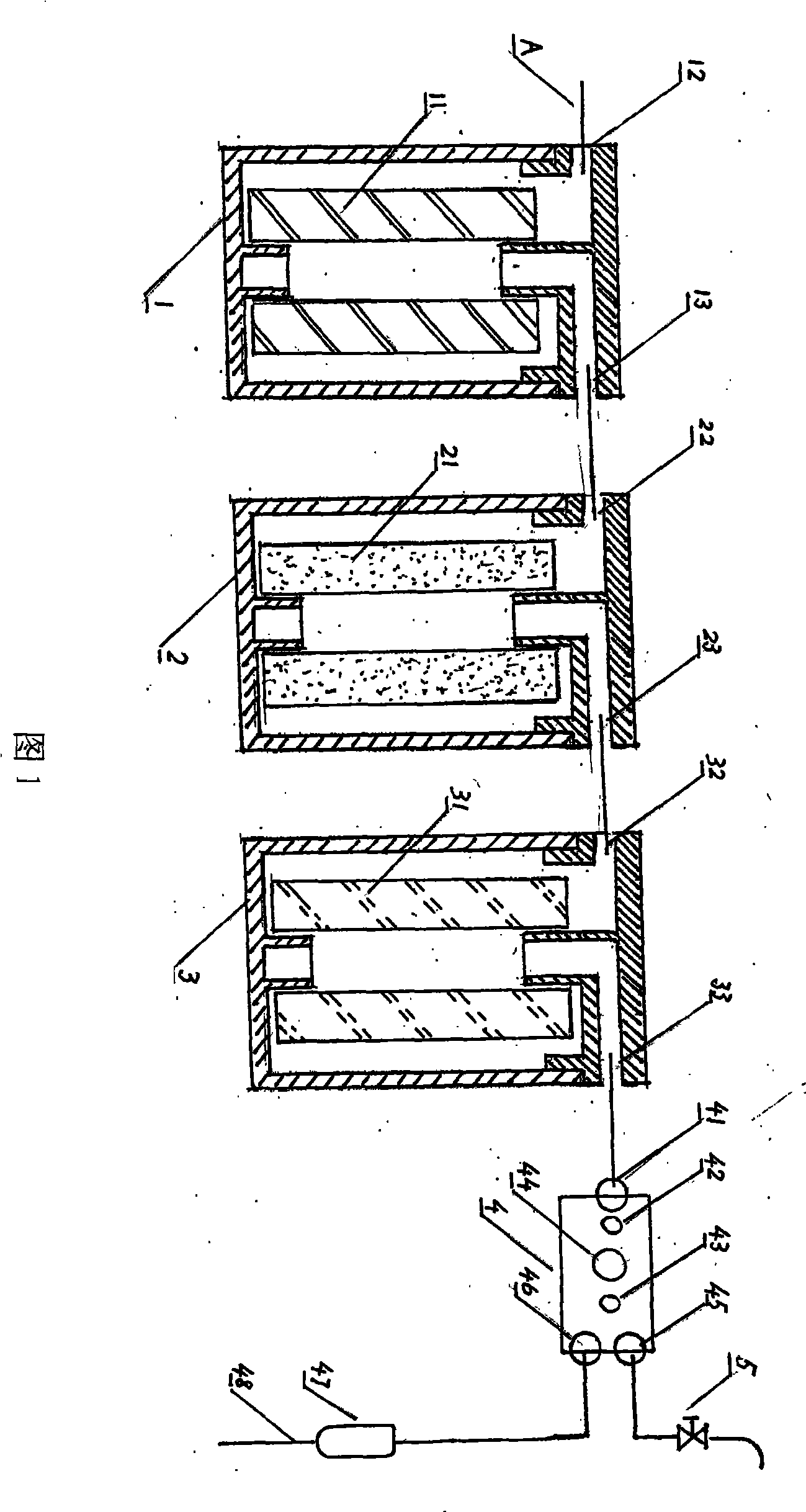

Embodiment 1

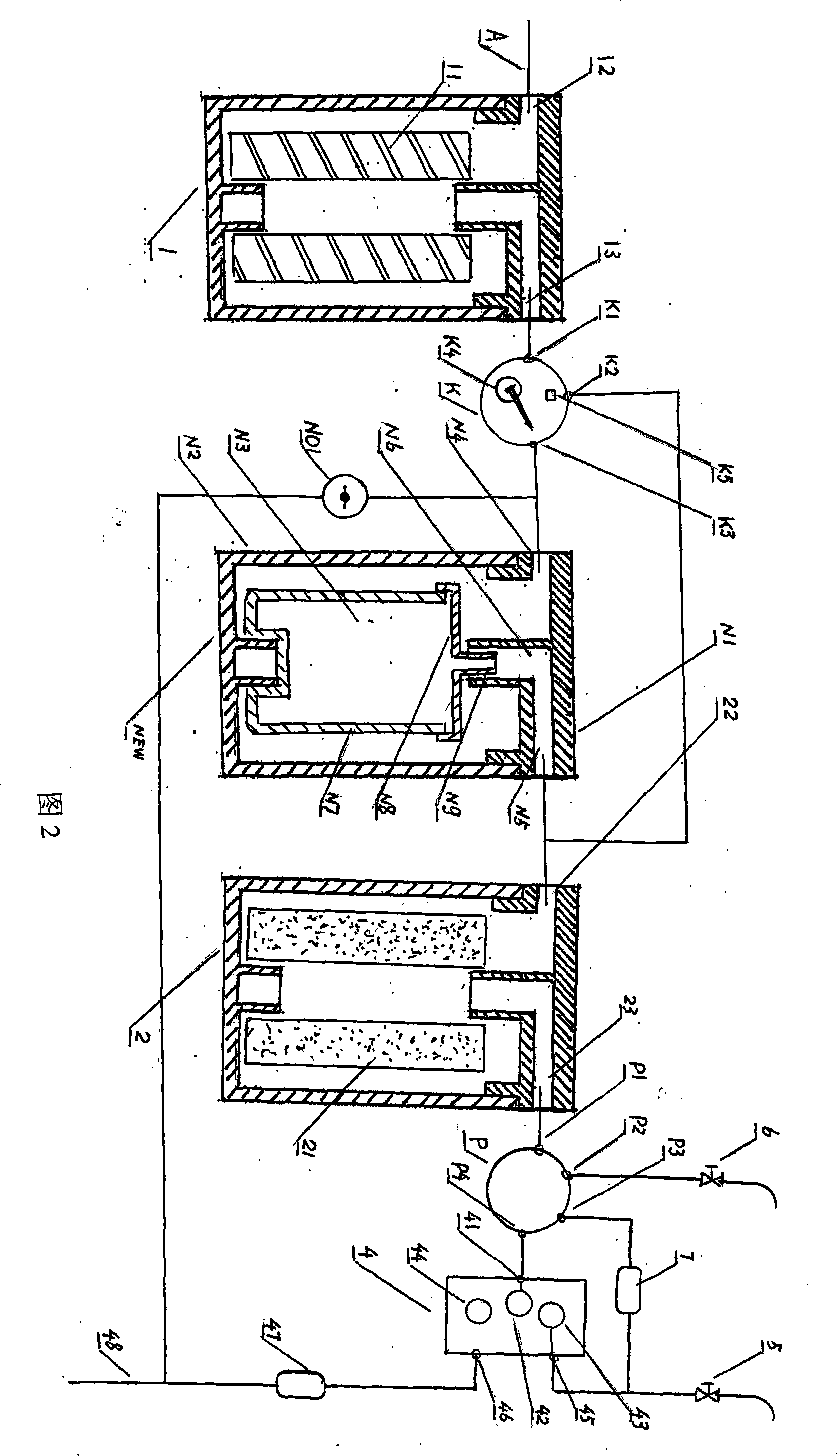

[0051]Embodiment 1: As shown in Figure 2, the components included in the present invention are: PP cotton coarse filter unit (1), microfiltration filter unit (NEW), active carbon filter unit (2), reverse osmosis host (4), pure Faucet (5), water purification faucet (6), water purification flow limiter (7), four-way (P), and three-way reversing valve (K) that can be selected by different control methods, normally open solenoid valve (KA ), normally closed solenoid valve (KB), ball valve (N02);

[0052] The PP cotton coarse filter unit (1) contains a PP cotton coarse filter element (11), a coarse filter inlet (12), and a coarse filter outlet (13);

[0053] The microfiltration filter unit (NEW) includes a filter cover (N1), a filter bucket (N2), and a microfiltration filter element (N3); the filter cover (N1) is provided with a microfiltration water inlet (N4), a microfiltration water outlet (N5 ), the central diversion tube (N6); the microfiltration filter element (N3) contains ...

Embodiment 2

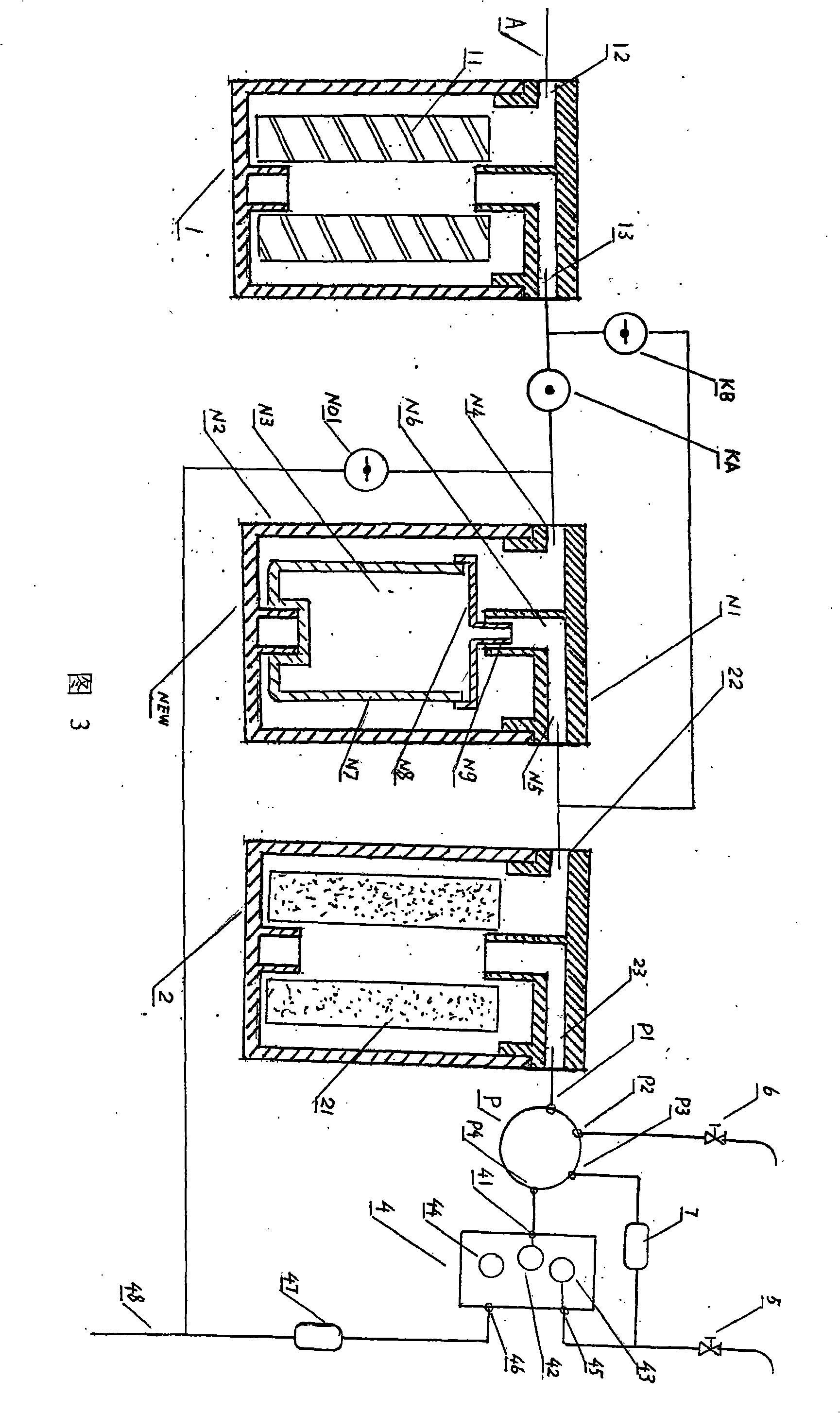

[0075] Embodiment two is shown in Figure 3:

[0076] Embodiment one shown in Fig. 2 adopts semi-automatic mode to carry out recoil to filter membrane (N7), and present embodiment then adopts automatic mode to carry out recoil to filter membrane (N7), and its gist is to use a normally open electromagnetic valve ( KA) and a normally closed solenoid valve (KB) to replace the three-way reversing valve (K) in embodiment one; under the control of the reverse osmosis control system (44), by solenoid valves (KA), (KB) The linkage with (N01) opens and closes two different waterways, and its characteristics are shown in Figure 3:

[0077] 1. The water outlet (13) of the PP cotton coarse filtration system (1) is connected with a tee with a pipe, and the other two ports of the tee are connected with the water inlet of the normally open solenoid valve (KA) with a pipe , one is connected with the water inlet of the normally closed solenoid valve (KB) by a pipeline;

[0078] 2. The water o...

Embodiment 3

[0082] Embodiment 3 is shown in Figure 3:

[0083] Embodiment 1 shown in Figure 2 uses a semi-automatic method to backflush the filter membrane (N7), and this embodiment uses a manual method to backflush the filter membrane (N7). The ball valve (N02) is used to replace the normally closed solenoid valve (N01), and its characteristics are shown in Figure 3;

[0084] Connect the outlet (K3) of the three-way reversing valve (K) to the other port of the three-way of the water inlet (N4) of the microfiltration unit (NEW), and connect the water inlet of the ball valve (N02) with a pipe , the water outlet of the ball valve (N02) is then connected with another port of the tee connecting the concentrated water restrictor (47) water outlet and the concentrated water discharge pipe (48) with a pipeline;

[0085] In this embodiment, turning the handle (K4) of the three-way reversing valve (K) can organize two waterways that are opened and closed one after the other. One is to open the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com