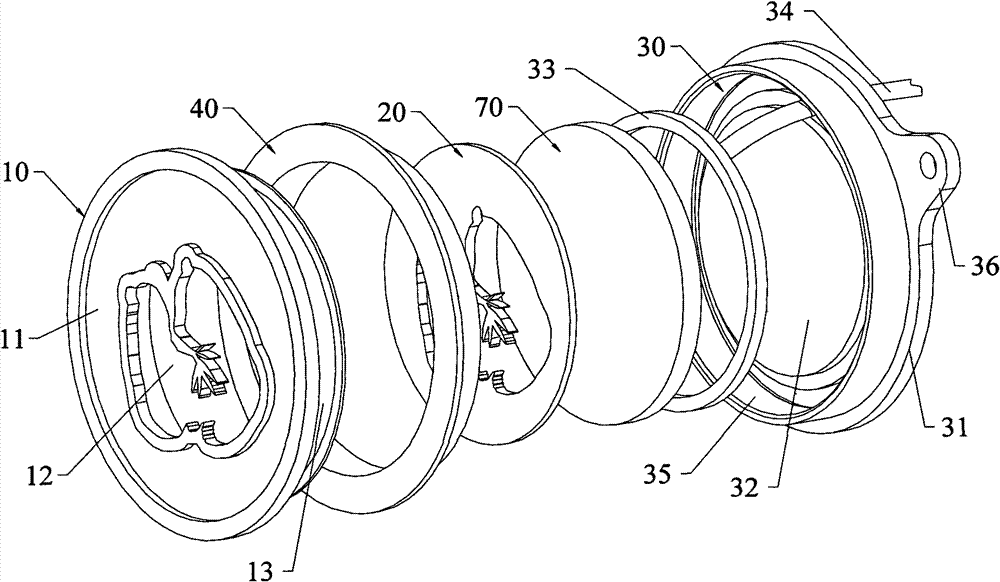

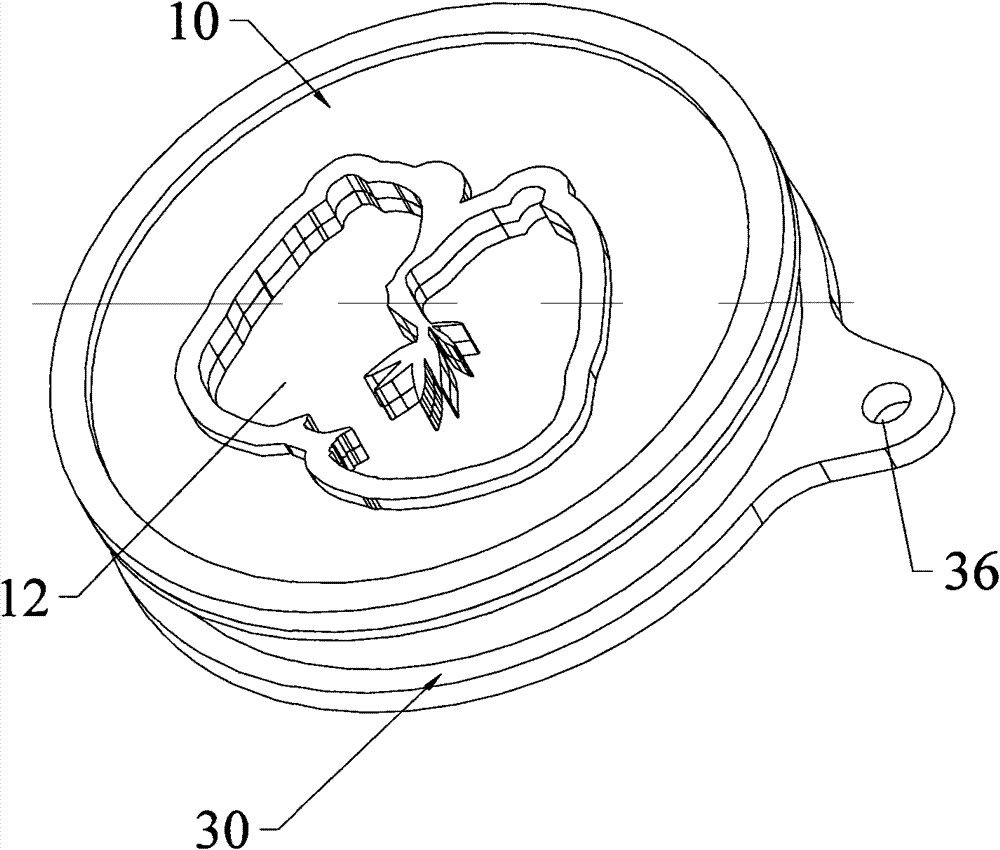

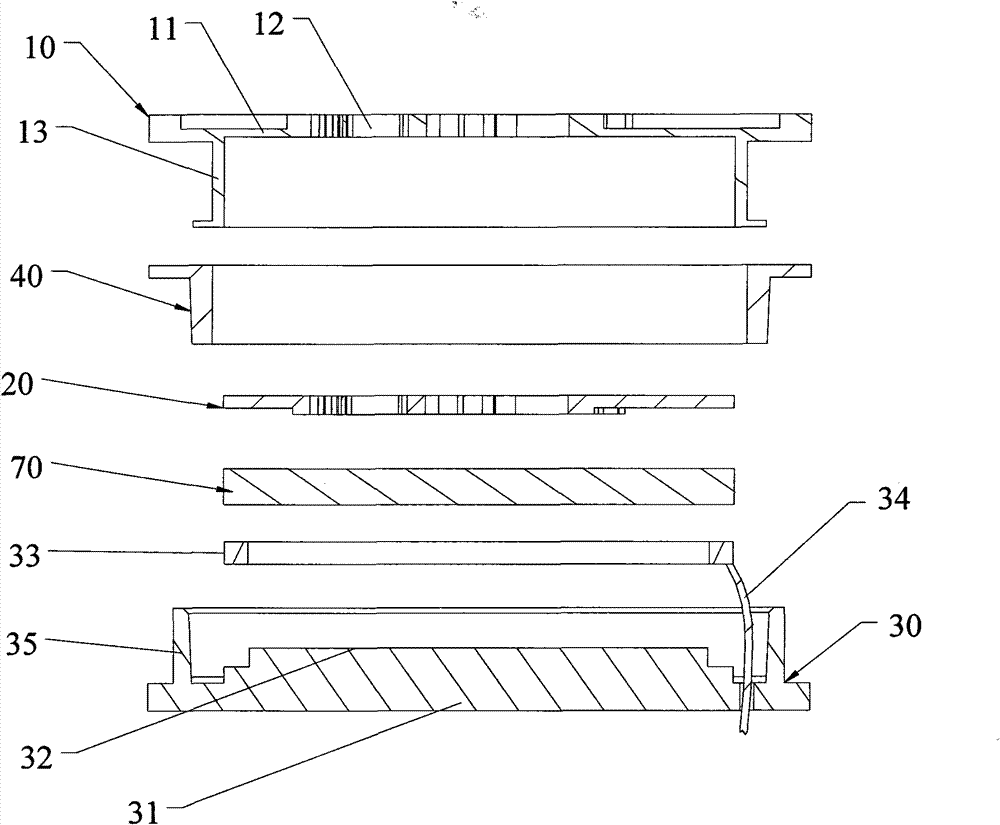

Protective clamp for local metal plating of workpiece and cyanide-free gold plating method thereof

A technology for protecting fixtures and parts, applied in the field of protecting fixtures, can solve the problems of easy contamination of the workpiece surface and complicated operation, and achieve the effects of good appearance of the coating, safe operation, and avoidance of toxicity and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Sodium gold sulfite (Na 3 Au(SO 3 ) 2 ) or gold potassium citrate is 1g; sodium sulfite (Na 2 SO 3 ) is 1g; ammonium chloride (NH 4 Cl) is 5g; thiourea is 1g; water is 1 liter.

[0060] First, weigh all the compounds in proportion to the container, add distilled water to stir and dissolve; then, clamp the silver commemorative coin with the protective fixture that is partially metal-plated above the workpiece, exposing the part that needs to be metal-plated, and then put the The fixture of the commemorative coin is hung on the hanger hook. After degreasing and cleaning, immerse in the plating solution, connect the power cord and the conductive lead on the fixture, turn on the power and start plating, and place the silver commemorative coin immersed in the plating solution to be gold-plated Gradually golden yellow appears until it is completely plated, and the plating is over; finally, take out the jig containing the silver commemorative coin, clean it, remove the ji...

Embodiment 2

[0062] Sodium gold sulfite (Na 3 Au(SO 3 ) 2 ) or gold potassium citrate is 40g; sodium sulfite (Na 2 SO 3 ) is 100g; ammonium chloride (NH 4 Cl) is 55g; thiourea is 70g; water is 1 liter.

[0063] First, weigh all the compounds in proportion to the container, add distilled water to stir and dissolve; then, clamp the silver commemorative coin with the protective fixture that is partially metal-plated above the workpiece, exposing the part that needs to be metal-plated, and then put the The fixture of the commemorative coin is hung on the hanger hook. After degreasing and cleaning, immerse in the plating solution, connect the power cord and the conductive lead on the fixture, turn on the power and start plating, and place the silver commemorative coin immersed in the plating solution to be gold-plated Gradually golden yellow appears until it is completely plated, and the plating is over; finally, take out the jig containing the silver commemorative coin, clean it, remove t...

Embodiment 3

[0065] Sodium gold sulfite (Na 3 Au(SO 3 ) 2 ) or gold potassium citrate is 21g; sodium sulfite (Na 2 SO 3 ) is 50g; ammonium chloride (NH 4 Cl) is 30g; thiourea is 36g; water is 1 liter.

[0066] First, weigh all the compounds in proportion to the container, add distilled water and stir to dissolve; then, clamp the silver commemorative coin with the protective fixture for partial metal plating of the above-mentioned workpiece, exposing the part that needs to be metal-plated, and then put the The fixture of the commemorative coin is hung on the hanger hook. After degreasing and cleaning, immerse in the plating solution, connect the power cord and the conductive lead on the fixture, turn on the power and start plating, and place the silver commemorative coin immersed in the plating solution to be gold-plated Gradually golden yellow appears until it is completely plated, and the plating is over; finally, take out the jig containing the silver commemorative coin, clean it, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com