Method and apparatus for discharge of fluidized bed in coated controlled release fertilizer production

A technology of unloading device and fluidized bed, which is applied in fertilization device, fertilizer mixture, application and other directions, can solve the problems of low production capacity of coated fluidized bed, volatilization and waste of coating solvent, and long production cycle of fluidized bed, etc. Achieve the effect of being beneficial to equipment maintenance, avoiding frequent startup and shortening the unloading cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

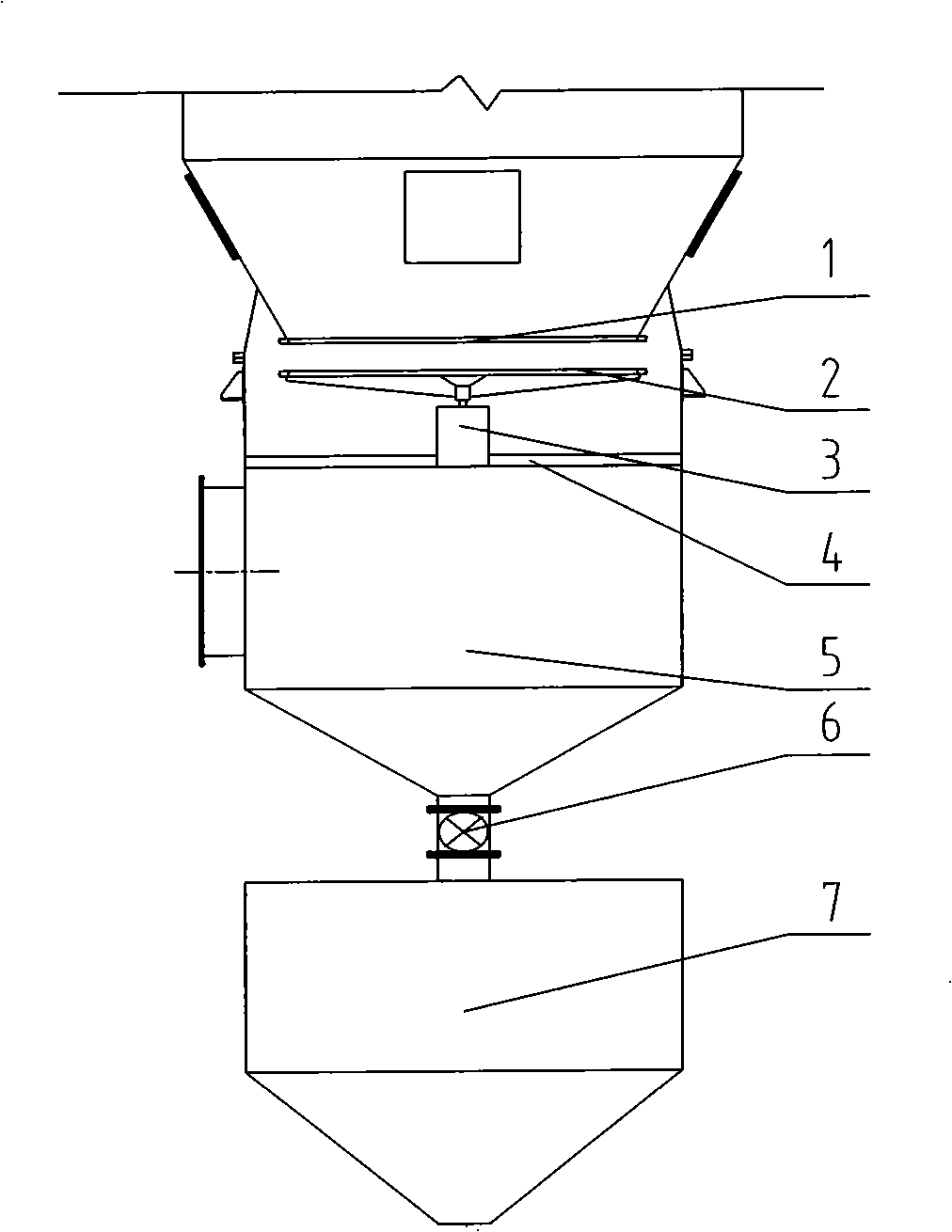

[0023] Depend on figure 1 It can be seen that the unloading device of the fluidized bed of the present invention includes a jack 3, a discharge bin 5, an air locker 6 and a finished product bin 7, wherein the air distribution plate 2 is separated from the sealing plate 1 by the jack 3 And compress, jack 3 is fixed on the support 4, and is installed in the unloading silo 5 together with support 4, and the outlet of unloading silo 5 is connected with finished product silo 7 by air locker 6. The air distribution plate 2 is a circular flat type air distribution plate, and the jack is an ordinary jack.

Embodiment 2

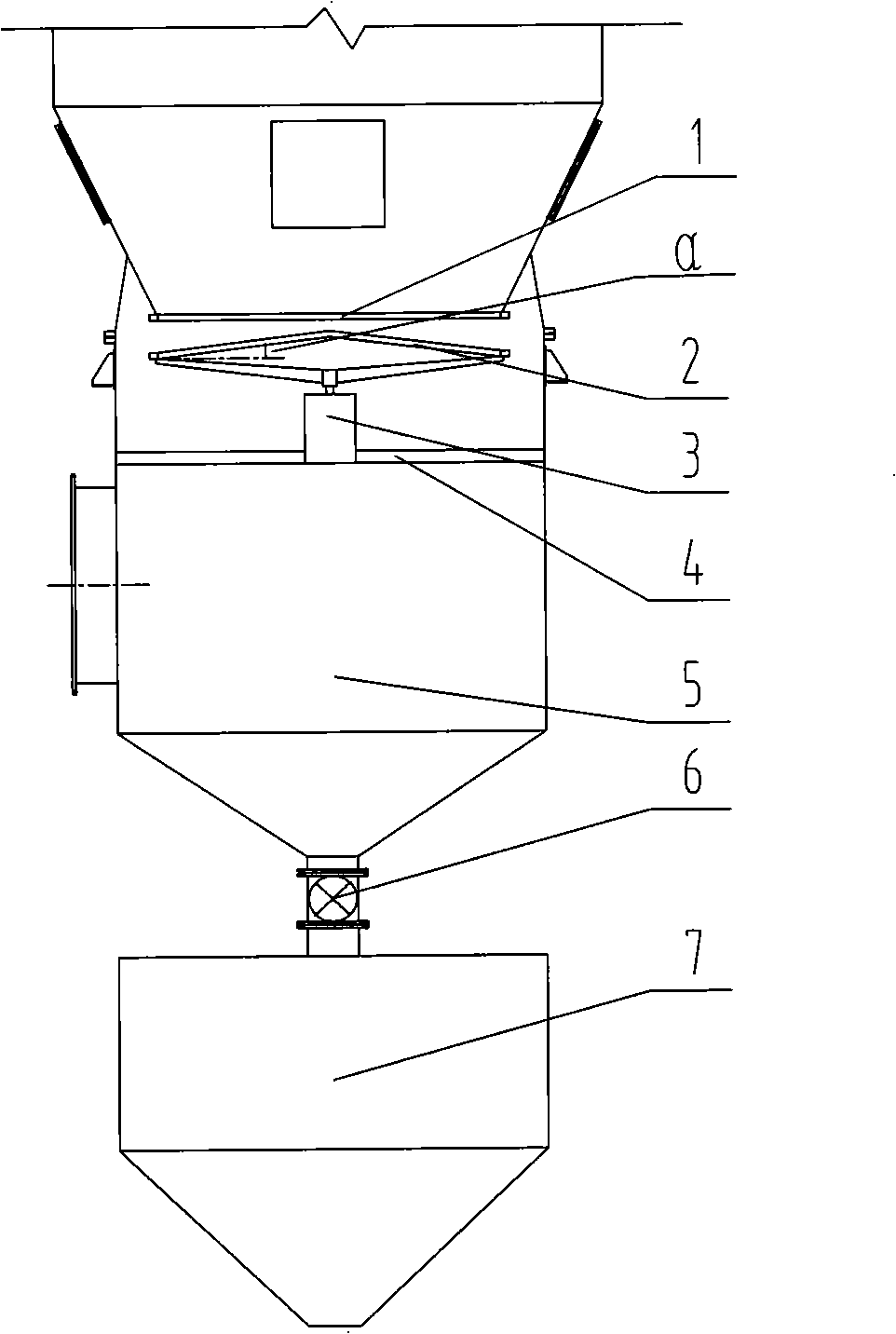

[0025] A kind of unloading device of fluidized bed of the present invention, structure such as figure 2 As shown, the difference from Example 1 is that the air distribution plate 2 is a conical air distribution plate with a cone angle α≤5°, and the jack 3 is an air pressure jack controlled by a solenoid valve.

Embodiment 3

[0027] Utilize the unloading device described in embodiment 1 or 2, carry out the unloading in the production of coated controlled-release fertilizer, specific operation steps:

[0028] A. Use the jack 3 to lower the air distribution plate 2 by 100-300mm to separate it from the sealing plate 1;

[0029] B. The material on the air distribution plate 2 is discharged into the discharge bin 5 under the blowing of gravity and fluidizing gas;

[0030] C. The material in the discharge bin 5 enters the finished product bin 7 through the air locker 6;

[0031] After the unloading is completed, use the jack 3 to lift the air distribution plate 2 and press the sealing plate 1 so that the next cycle of production can be added.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap