Gantry type frame for detecting white body performance of automobile

A body-in-white, gantry-type technology, applied in the field of gantry-type frame, can solve the problems of inconvenient disassembly, adjustment, uncoordinated support rigidity, large material consumption, etc., and achieve the effect of convenient installation and adjustment, reduction of consumables, and good expandability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

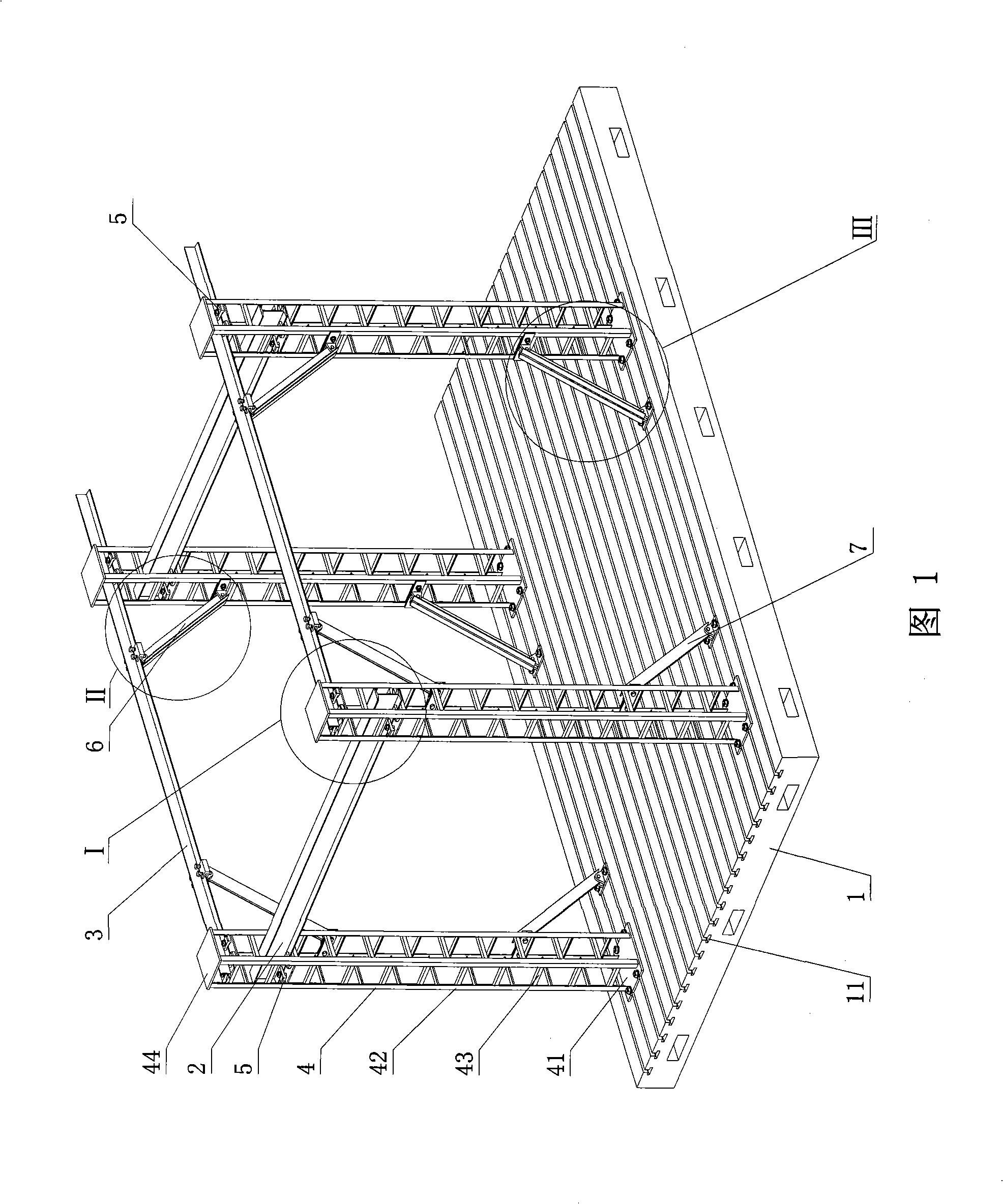

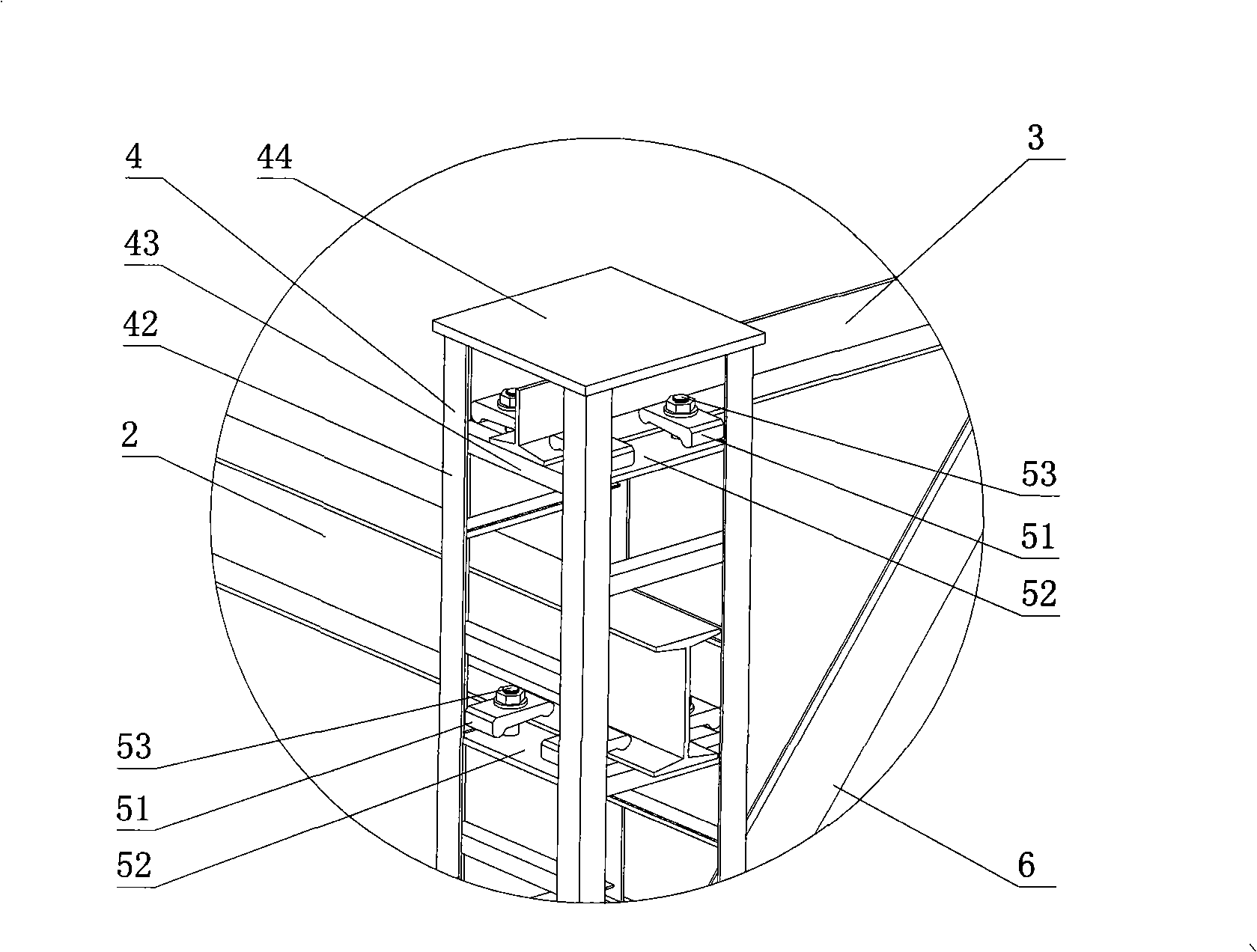

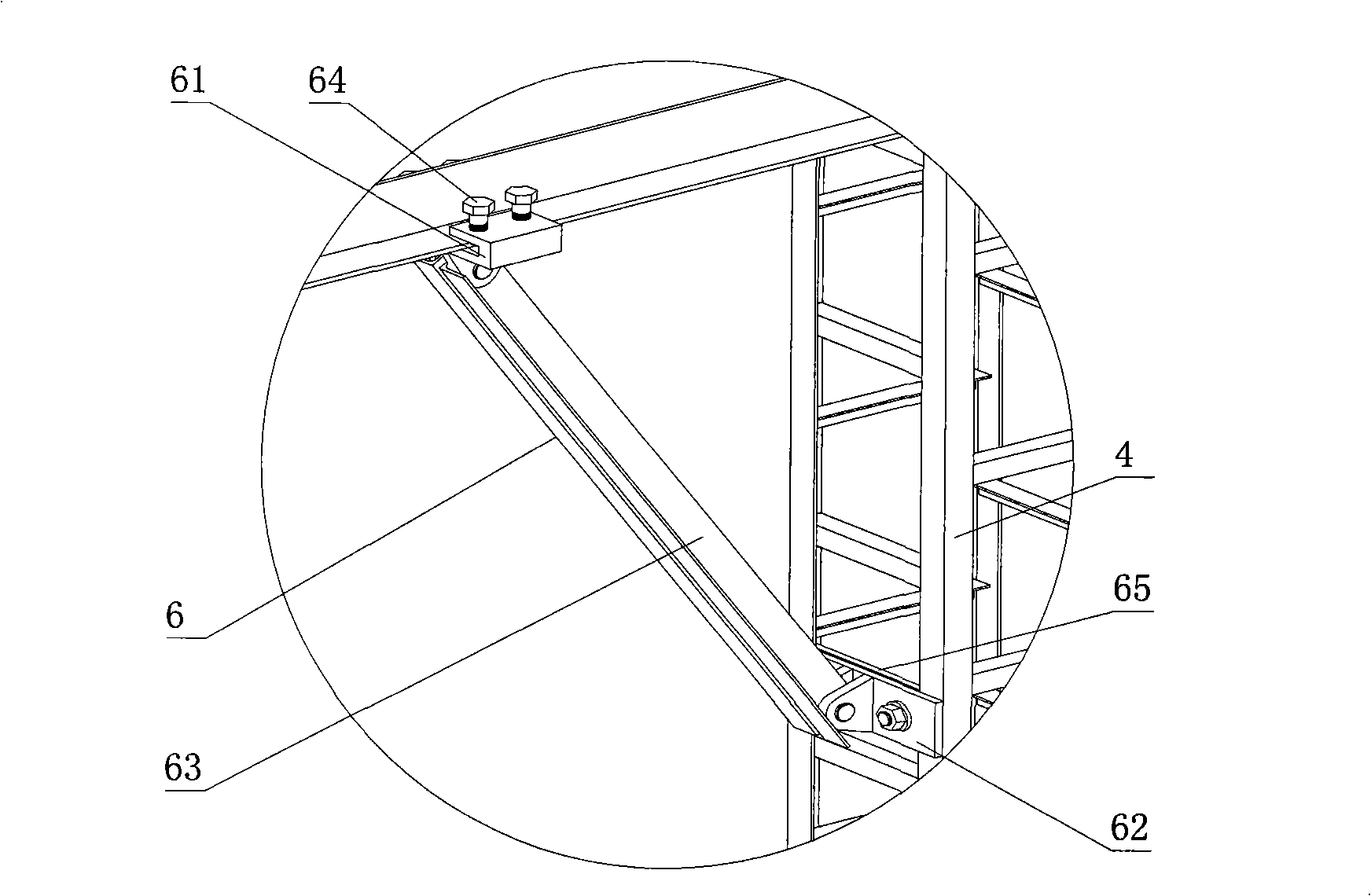

[0034]As shown in Fig. 1 to Fig. 5, a kind of gantry type framework for automobile body-in-white performance detection of the present invention comprises beam 2, longitudinal beam 3, truss structure square column 4, clamping device 5 and is provided with a plurality of T The mounting base 1 of the groove 11, the truss structure square column 4 is provided with four pieces and arranged in a rectangle, each truss structure square column 4 is composed of four vertical bars 42, a plurality of cross bars 43, and is located at the bottom of the four vertical bars 42 The bottom plate 41 and the top plate 44 arranged on the top of four vertical bars 42 are composed. Compared with the round steel tube, square steel tube, I-beam and other columns in the prior art, the truss structure square column 4 not only reduces the consumables, but also ensures The whole device is sufficiently rigid. Each bottom plate 41 is fixed on the installation base 1 through the fasteners placed in the T-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com