Fire-proof test device of concrete multi-span continues beam or plate

A test device, concrete technology, applied in the direction of measuring device, machine/structural component testing, material inspection product, etc., can solve the problem of inability to measure fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

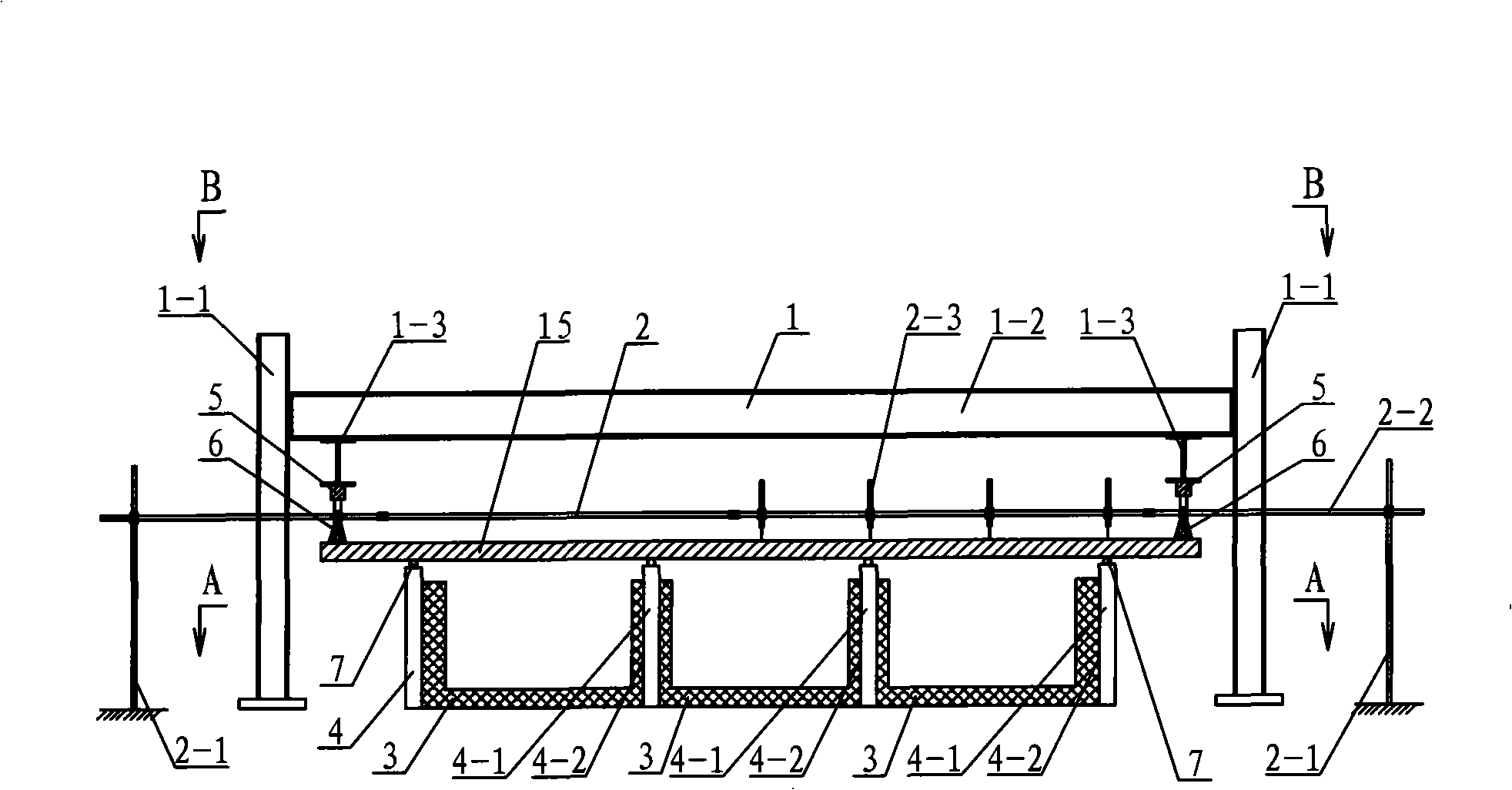

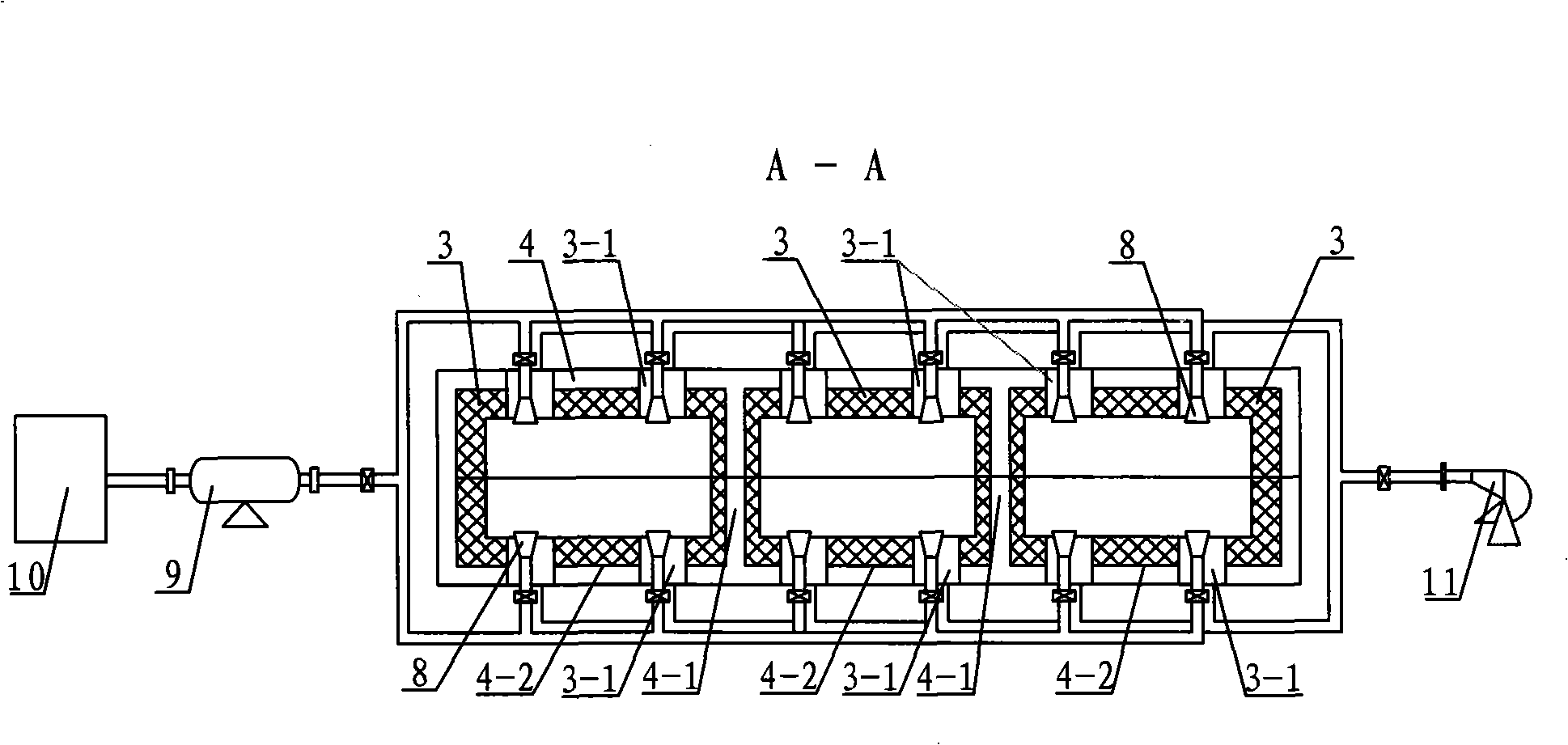

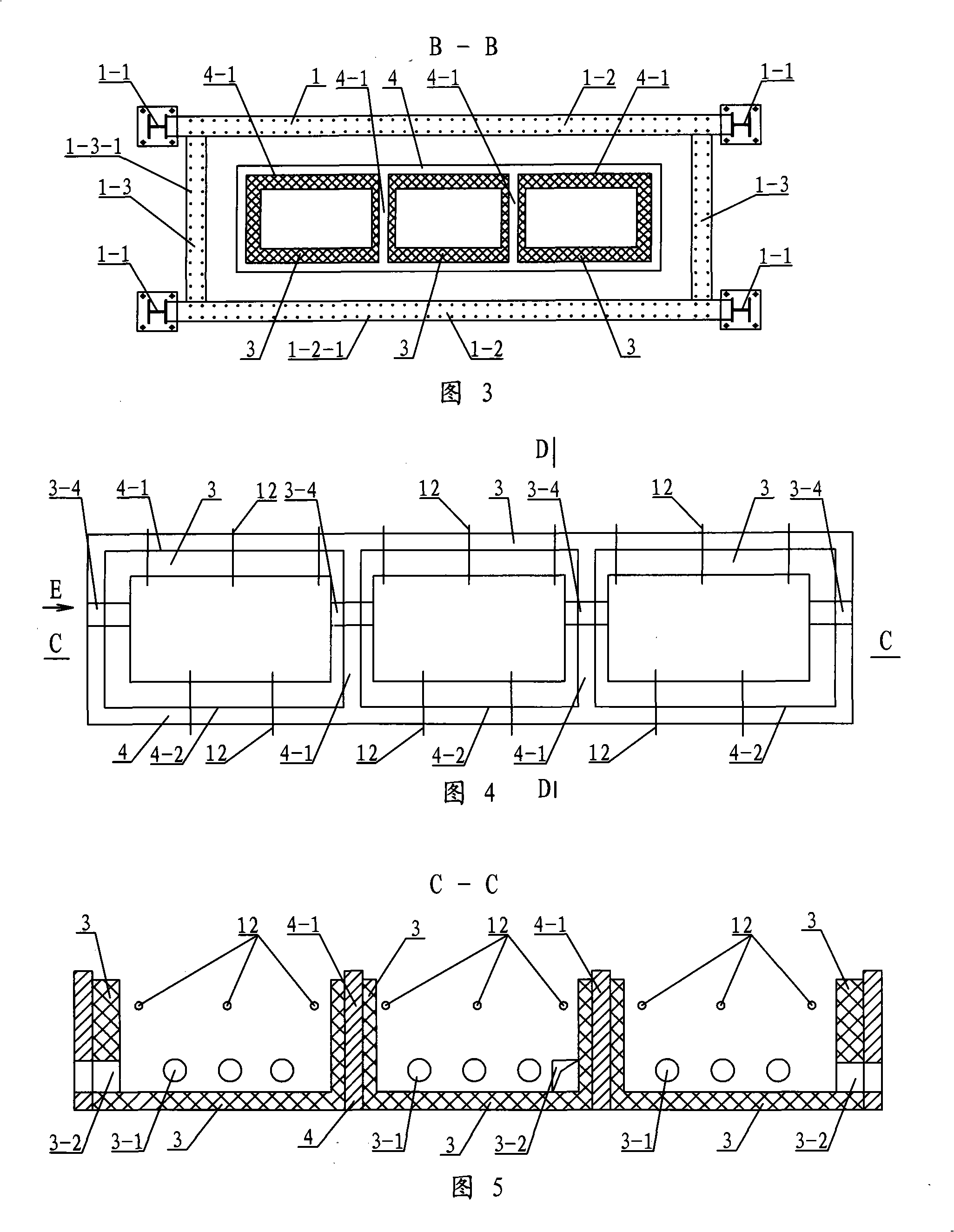

[0007] Specific implementation mode one: combine Figure 1 to Figure 6 and Fig. 8 illustrate this embodiment, this embodiment comprises reaction force frame 1, and reaction force frame 1 is made up of four columns 1-1, two reaction force longitudinal beams 1-2 and at least one reaction force beam 1-3, The two ends of each reaction force longitudinal beam 1-2 are respectively connected with the side end surfaces of two upright columns 1-1 by high-strength bolts, and the reaction force beam 1-3 is located between the two reaction force longitudinal beams 1-2, and the reaction force The position of the beam 1-3 can be adjusted along the reaction beam 1-2 according to the position of the applied load or reaction constraint required by the test, and the two ends of the reaction beam 1-3 respectively pass through the two reaction beams 1-2 High-strength bolt fastening, it also includes at least one displacement measuring device 2, at least two-span furnace body 3, specimen support 4...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 , Figure 5 and Image 6 The present embodiment will be described. In this embodiment, the upper plane of the furnace body 3 is lower than the upper plane of the specimen holder 4 . This design can ensure that the specimen has enough deformation space.

specific Embodiment approach 3

[0009] Specific embodiment three: this embodiment is described in conjunction with Fig. 9, the furnace body wall around the furnace body 3 of the present embodiment is formed by refractory bricks, and the furnace body wall around the furnace body 3 is formed by ordinary red bricks. The furnace body 3 is filled with refractory fibers between the inner wall and the outer wall around the furnace body 3, and the bottom of the furnace body 3 is made of two layers of refractory bricks. This design makes the furnace body 3 have a good thermal insulation effect, simple structure and low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com