Release paper for synthetic leather

A technology for synthetic leather and release paper, applied in the field of release paper, can solve the problems of high cost, many production processes, high requirements for paper base, etc., and achieve the effect of low cost and high gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

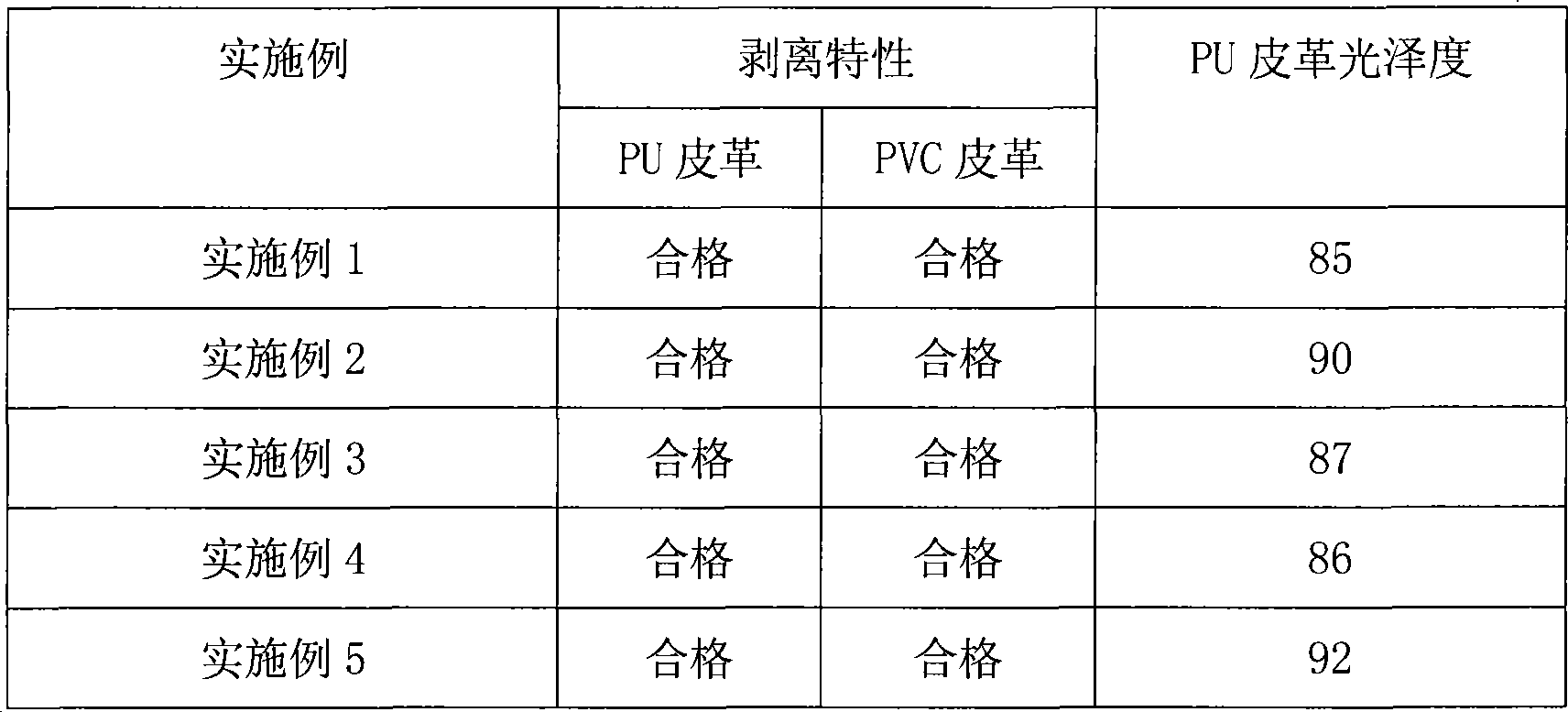

Examples

Embodiment 1

[0057] Preparation of Multifunctional Layer Coating Solution

[0058] 50 parts by weight of styrene-acrylic emulsion;

[0059] 50 parts by weight of water;

[0060] 3 parts by weight of sodium dodecylsulfonate;

[0061] First add 50 parts by weight of styrene-acrylic emulsion [German BASF model: 296DS solid content: 50%] to 50 parts by weight of aqueous solution, mix the solution evenly with a glass rod, and then add 3 parts by weight of dodecylsulfonic acid Sodium is added therein, and the stirring is continued to make a multi-functional layer coating liquid, which is ready for use.

[0062] The multi-functional layer coating solution was coated on a 200-gram photographic base paper with a doctor blade, heated at 80° C. for 30 seconds, and cured to form a film with a film thickness of 30 microns. Then coat the release layer with a silk bar on the multifunctional layer, cure at 100° C. for 40 seconds, and have a film thickness of 30 microns to obtain a leather release paper...

Embodiment 2

[0064] Preparation of Multifunctional Layer Coating Solution

[0065] 40 parts by weight of styrene-butadiene emulsion;

[0066] 40 parts by weight of styrene-acrylic emulsion;

[0067] 20 parts by weight of water;

[0068] 2 parts by weight of dodecyl dimethyl benzyl ammonium chloride;

[0069] First 20 parts by weight of water are added to the styrene-butadiene emulsion [Germany Bayer model: F2040 solid content: 50%] and 40 parts by weight of styrene-acrylic emulsion [German BASF model: 296DS solid content: 50%] by 40 parts by weight In the mixed emulsion formed, use a glass rod to mix the solution evenly, then add 2 parts by weight of dodecyl dimethyl benzyl ammonium chloride to it, continue to stir evenly, and make a multifunctional layer coating liquid, and wait for use.

[0070] The multi-functional layer coating solution was coated on 150-gram coated paper with a doctor blade, heated at 80° C. for 30 seconds and cured to form a film with a film thickness of 30 micro...

Embodiment 3

[0072] Preparation of Multifunctional Layer Coating Solution

[0073] 90 parts by weight of pure acrylic emulsion;

[0074] 10 parts by weight of water;

[0075] 1 part by weight of lauryl betaine;

[0076] First add 10 parts by weight of water to 90 parts by weight of pure acrylic emulsion [German BASF model: PA237 solid content: 50%], mix the solution evenly with a glass rod, and then add 1 part by weight of lauryl betaine Add it therein and continue to stir evenly to make a multi-functional layer coating solution for use.

[0077] The multi-functional layer coating solution was coated on a 180-gram photographic base paper with a doctor blade, heated at 80° C. for 30 seconds, and cured to form a film with a film thickness of 30 microns. Then coat the release layer with a silk bar on the multifunctional layer, cure at 100° C. for 40 seconds, and have a film thickness of 30 microns to obtain a leather release paper. Then, a peel test and a leather gloss test were performed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com