Heating start-up system of mine ventilation air methane oxidized apparatus

A technology of oxidation device and start-up system, which is applied in mine/tunnel ventilation, gas discharge, safety devices, etc., which can solve the inconvenient maintenance and replacement of heating wires, reduce the service life of ceramic regenerators, and cause large thermal stress of ceramic regenerators and other problems, to achieve the effect of easy control, prolonging life, and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

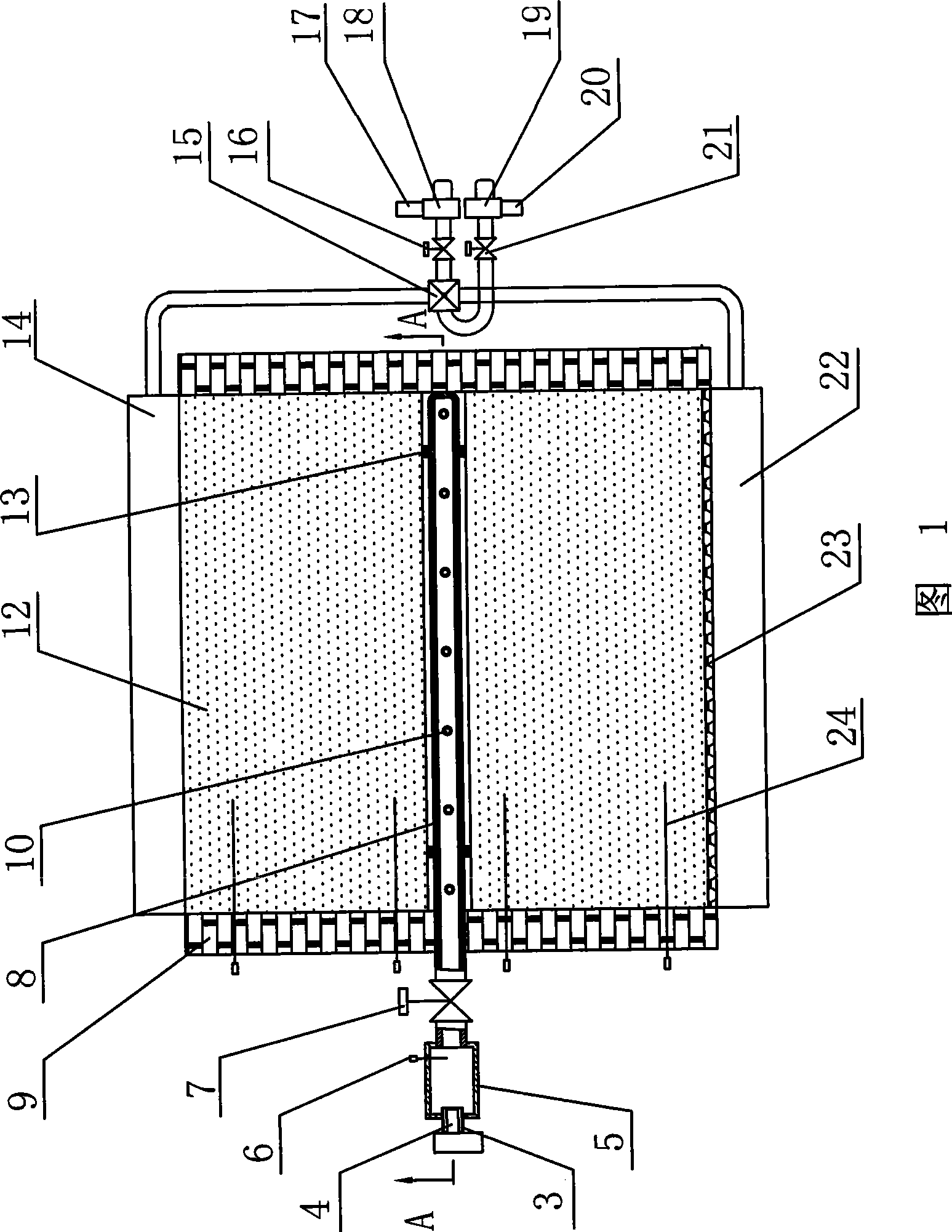

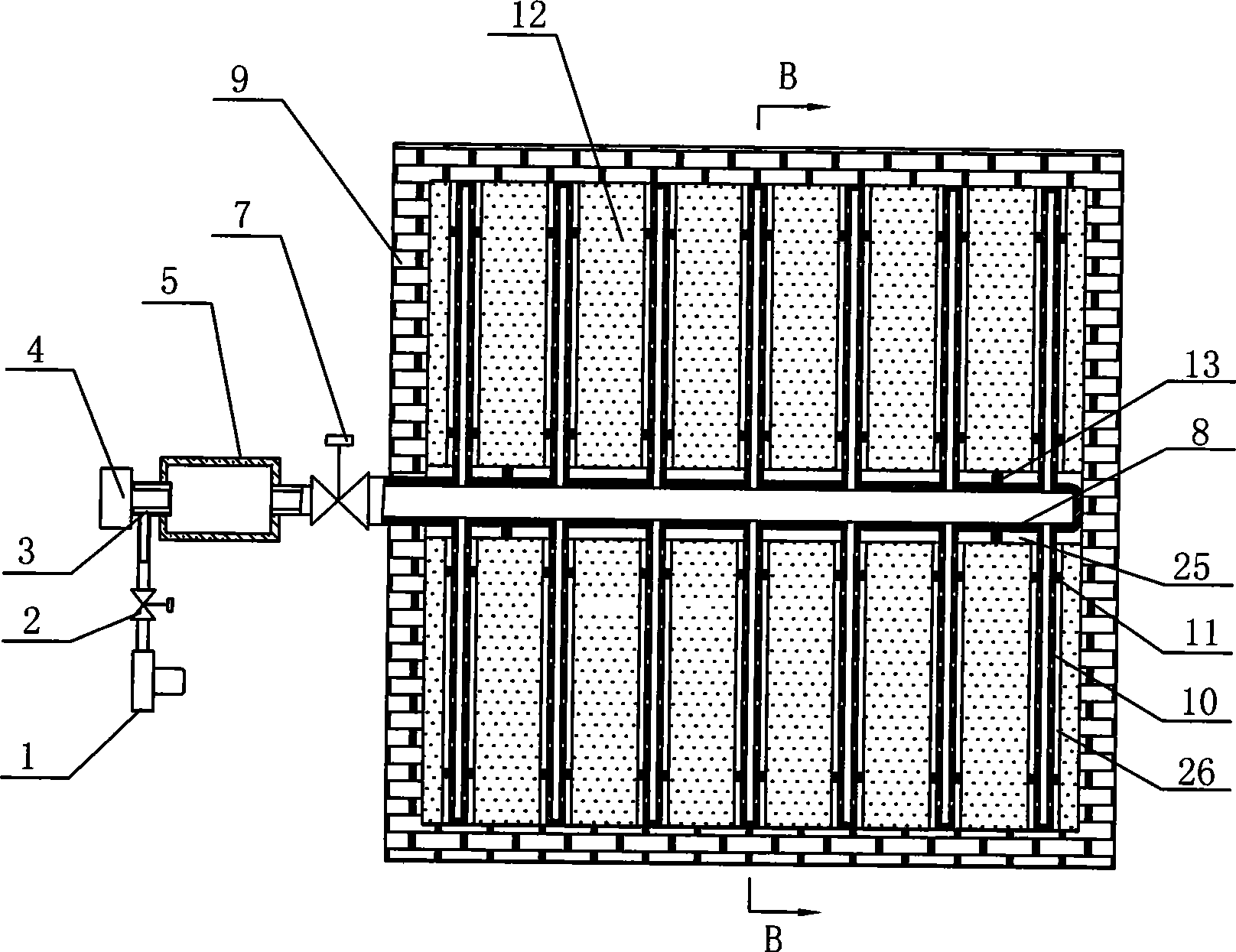

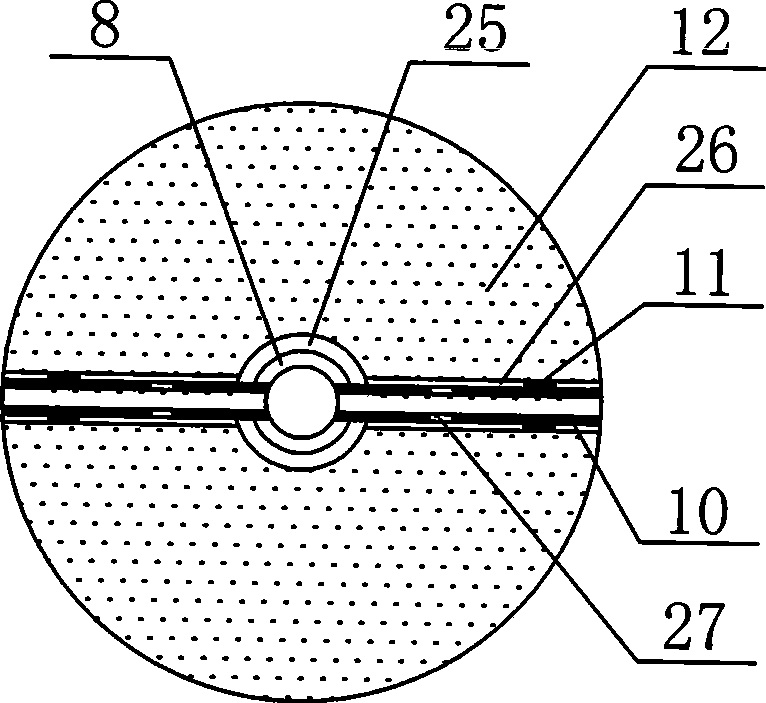

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] In the embodiment shown in Figures 1-4: upper inlet and outlet air guide distributor 14, four-way reversing valve 15, valve 16, exhaust air inlet pipe 17, blower 18, induced draft fan 19, exhaust pipe 20, valve 21 The lower inlet and outlet air guiding distributor 22 constitutes the air distribution device of the thermal countercurrent oxidation device for the exhaust gas in the mine. The fan 1 is connected to the air inlet 3 through the flow regulating valve 2, and the air inlet 3 is set on the combustion head of the burner 4, and communicated with the hot air temperature adjustment chamber 5; the hot air distribution main pipe 8 is placed in the center of the oxidation device body , and installed in the hole 25 of the ceramic regenerator 12 through the main pipe bracket 13, there is a gap between the outer wall and the ceramic regenerator 12, and the inlet end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com