Optical fibre coating cured auxiliary device of ultraviolet curing oven

An optical fiber coating and curing furnace technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problem of unstable optical fiber coating curing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

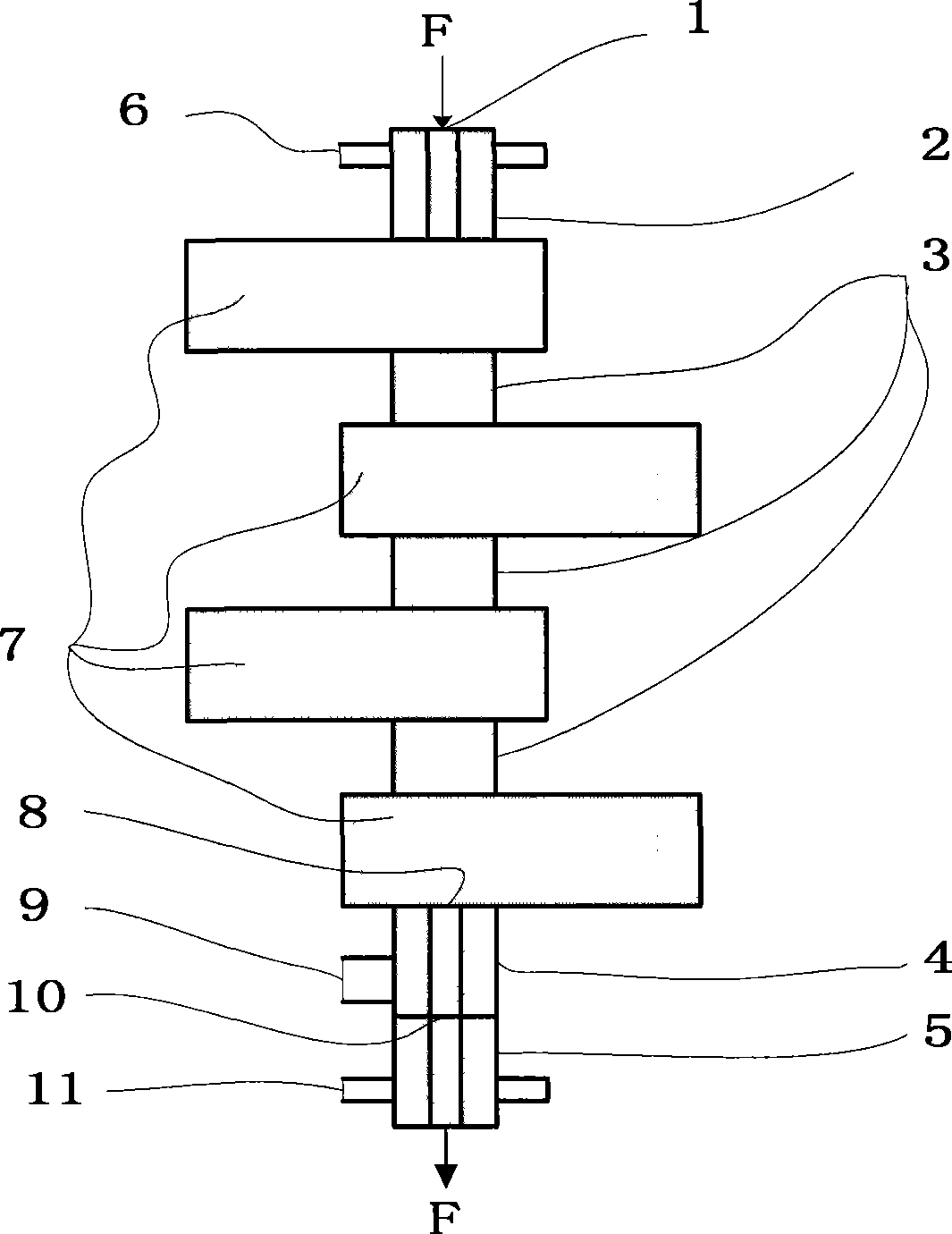

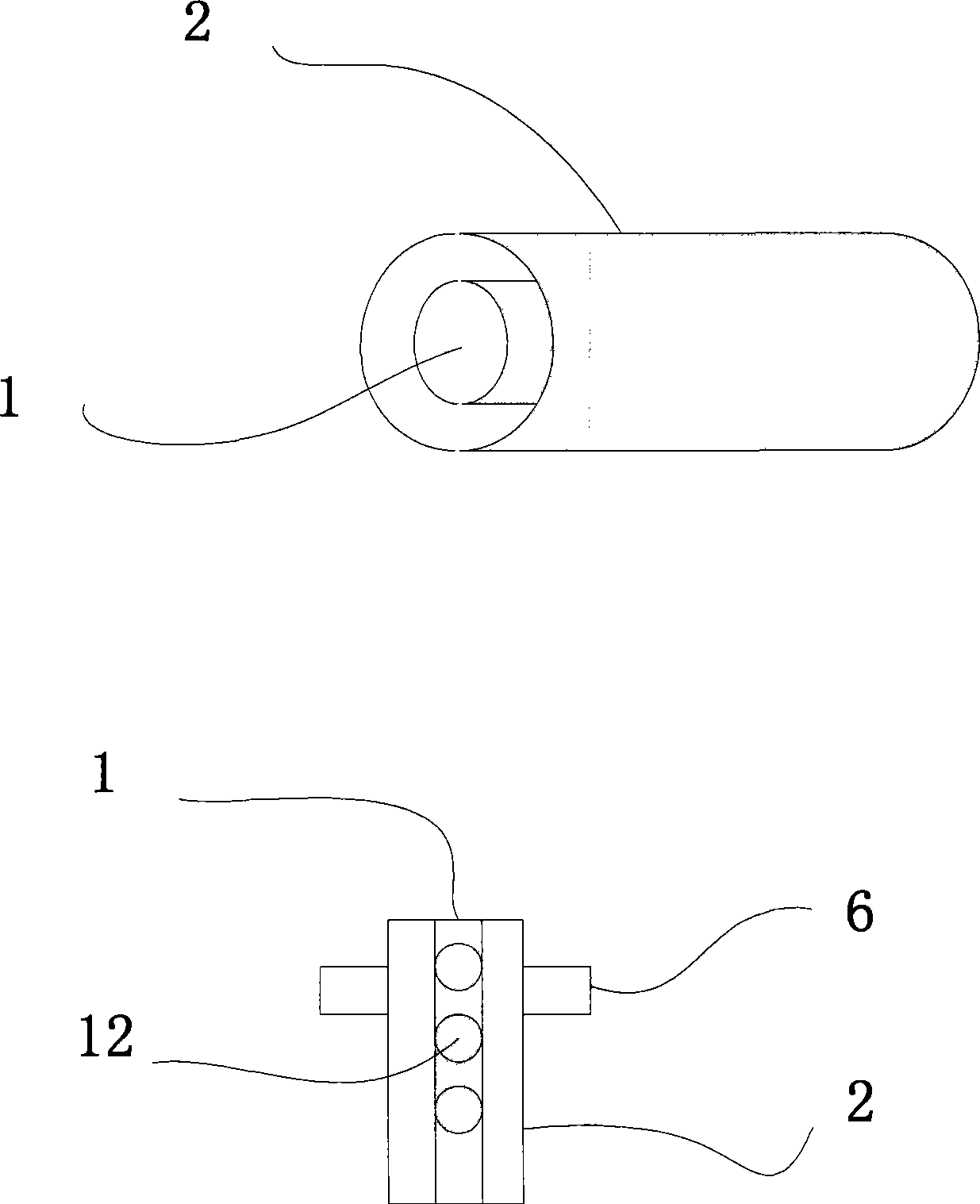

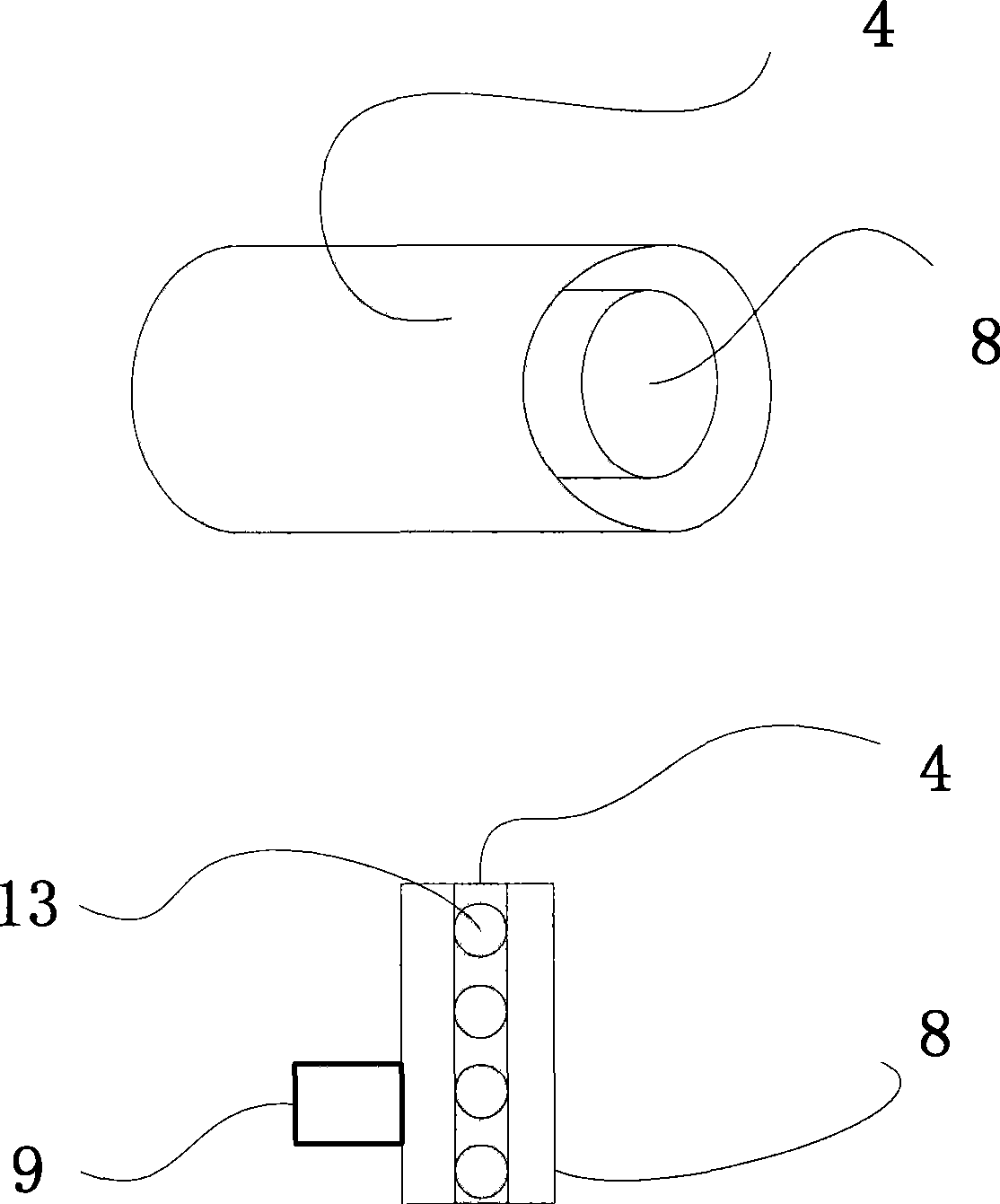

[0021] in figure 1 with figure 2 Among them, 1 is the internal cylindrical pipe of the gas seal device, 2 is the outer shell of the gas seal device, 6 is the nitrogen channel entering the gas seal device, and 12 is the small holes that are evenly distributed in the circumference of the embedded cylindrical pipe in order of height; in figure 1 Among them, 3 is the sealed connection device between each UV curing oven, 7 is the UV curing oven; figure 1 with image 3 Among them, 4 is the outer casing of the smoke exhaust device, 8 is the embedded pipe of the smoke exhaust device, 9 is the outward channel of the smoke exhaust device, and 13 is the small holes evenly distributed in the embedded pipe in order of height; figure 1 with Figure 4 Among them, 5 is the outer shell of the gas seal device, 10 is the cylindrical pipe embedded in the gas se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com