Electronic emitter and production method thereof, electron source and visual display unit

一种电子发射、制造方法的技术,应用在图像/图形显示管、电极系统制造、放电管/灯的制造等方向,能够解决电子漫射、表面粗糙度大、制造出电子发射器件等问题,达到性能卓越的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

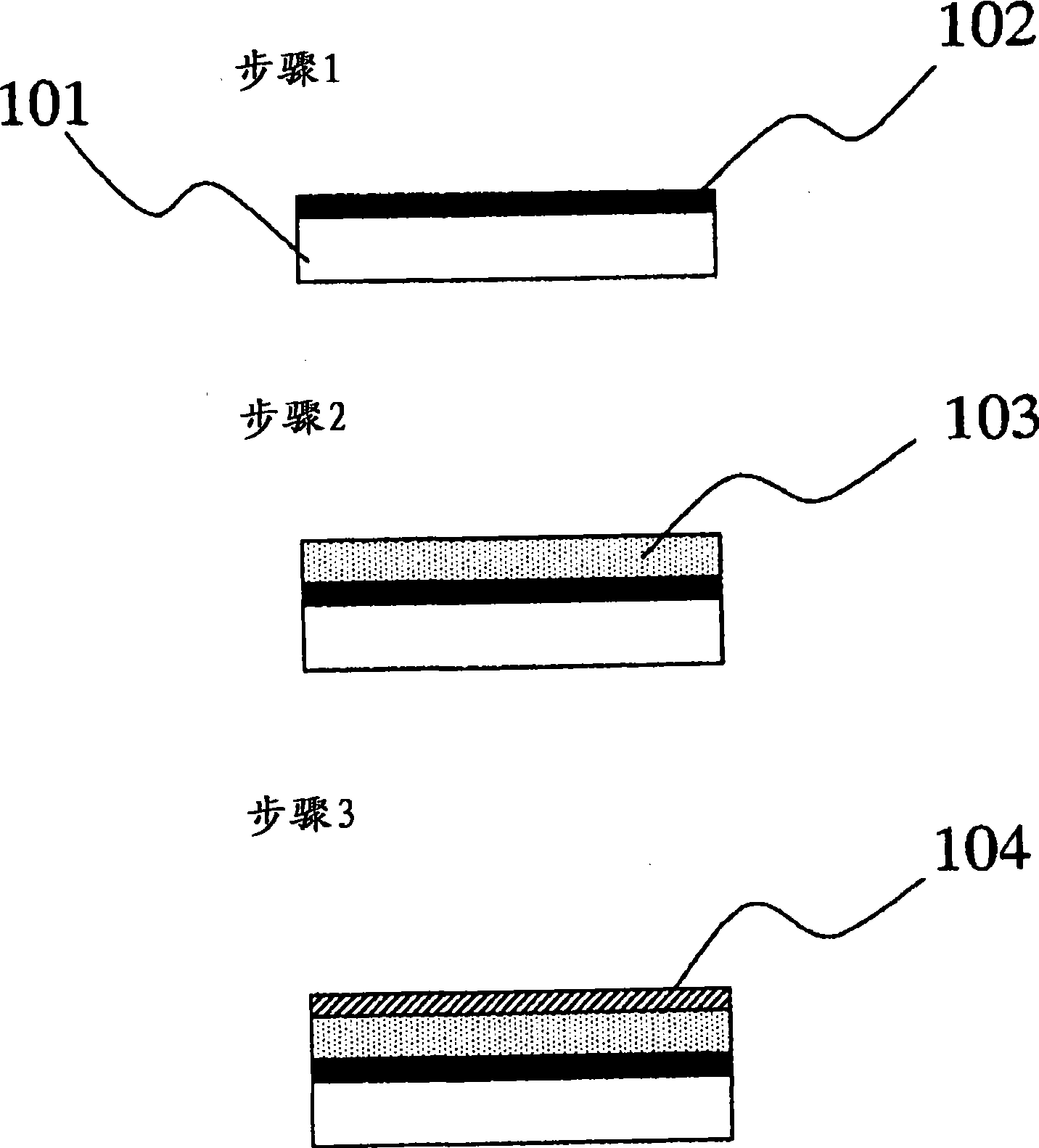

[0085] In the following, reference will be made to figure 1 The steps of manufacturing the electron emission film according to this example are described in detail.

[0086] (step 1)

[0087] First, quartz glass as the substrate 101 was sufficiently cleaned, and a Pt film as the cathode electrode 102 was formed on the substrate 101 with a thickness of 200 nm by the sputtering method.

[0088] (step 2)

[0089] A diamond-like carbon film containing Pt was formed as the electron emission film 103 on the cathode electrode 102 by using a co-sputtering method. The film thickness was about 30 nm, and the Pt density was about 20%.

[0090] (step 3)

[0091] The surface termination treatment was performed under the following conditions to form the hydrogen terminated surface 104 .

[0092] Process gas: CH 4 50 sccm

[0093] Pressure: 0.25Pa

[0094] ECR plasma power: 300W

[0095] Grid bias: -80V

[0096] Substrate Bias: +40V

[0097] Processing time: 30 seconds

[0098] ...

no. 2 example

[0101] In the following, reference will be made to figure 1 The steps of manufacturing the electron emission film according to this example are described in detail.

[0102] (step 1)

[0103] First, quartz glass as the substrate 101 was sufficiently cleaned, and a Pt film as the cathode electrode 102 was formed on the substrate 101 with a thickness of 200 nm by the sputtering method.

[0104] (step 2)

[0105] A Co-containing diamond-like carbon film was formed as the electron emission film 103 on the cathode electrode 102 by using a co-sputtering method. The film thickness was about 30 nm, and the Co density was about 20%.

[0106] (step 3)

[0107] The surface termination treatment was performed under the following conditions to form the hydrogen terminated surface 104 .

[0108] Process gas: CH 4 20 sccm

[0109] h 2 30 sccm

[0110] Pressure: 0.25Pa

[0111] ECR plasma power: 400W

[0112] Grid bias: 0V

[0113] Substrate Bias: +40V

[0114] Processing time:...

no. 3 example

[0118] In the following, reference will be made to figure 1 The steps of manufacturing the electron emission film according to this example are described in detail.

[0119] (step 1)

[0120]First, quartz glass as the substrate 101 was sufficiently cleaned, and a Pt film with a thickness of 200 nm as the cathode electrode 102 was formed on the substrate 101 by the sputtering method.

[0121] (step 2)

[0122] A carbon film is formed on the cathode electrode 102 by using a filament CVD (filament CVD) method. Thereafter, by implanting 1 atm% Co into the diamond-like carbon film by an ion implantation method, an electron emission film was formed. The film thickness was about 30 nm.

[0123] (step 3)

[0124] The surface termination treatment was performed under the following conditions to form the hydrogen terminated surface 104 .

[0125] Process gas: C 2 h 4 30 sccm

[0126] h 2 20 sccm

[0127] Pressure: 0.25Pa

[0128] ECR plasma power: 300W

[0129] Grid bias:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com