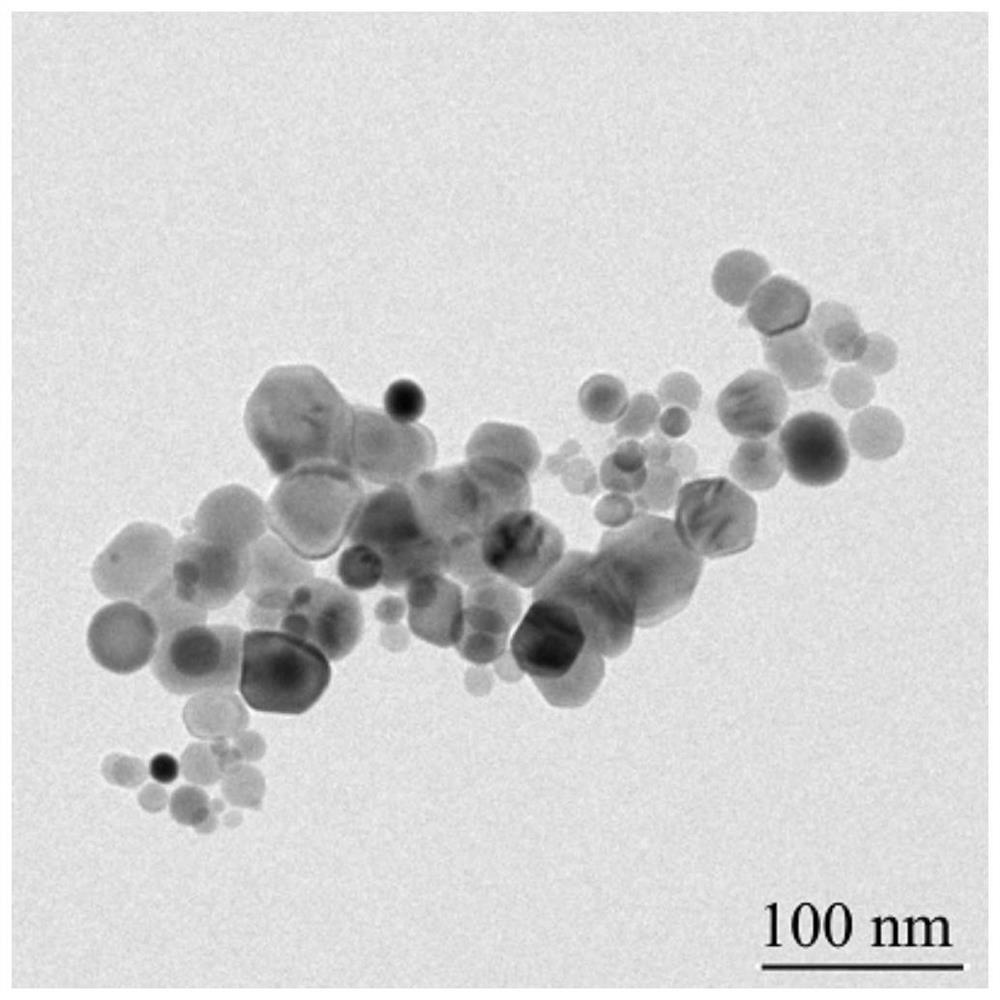

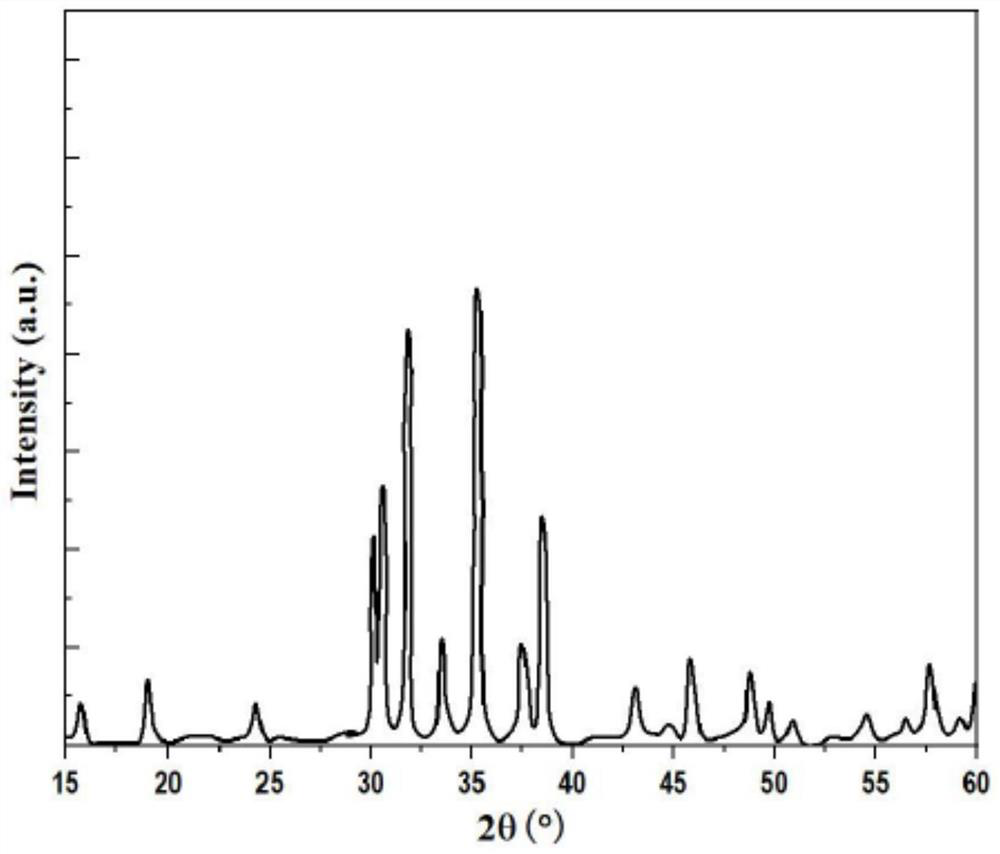

Cr<3+>-doped near-infrared nano fluorescent powder as well as preparation method and application thereof

A nano-phosphor and phosphor technology are applied in the field of near-infrared nano-phosphors doped with Cr3+ and their preparation, which can solve unfavorable encapsulation and propagation of ultraviolet excitation light, affect the conversion efficiency of near-infrared light, and are difficult to dope due to large size. Uniformity and other problems, to achieve the effect of easy industrial production, low price, low requirements for preparation equipment and conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] S1, choose Ga(NO 3 ) 3 , CrCl 3 , sodium hydroxide, sodium chloride, and water as raw materials, according to the phosphor chemical expression Ga 2-X o 3 :xCr 3+ The stoichiometric ratio of each chemical component in, weighed 1.99mmol Ga(NO 3 ) 3 , 0.01mmol CrCl 3 , 1mmol sodium hydroxide, 2mmol sodium chloride raw materials are mixed;

[0030] S2. Add 5 mL of water to the mixture obtained in step S1, grind for 15 minutes and mix well;

[0031] S3, vacuum drying the mixture obtained in step S2 for 20 minutes;

[0032] S4. Transfer the powder in step S3 to an alumina crucible, put it into a box furnace, and calcinate at 200° C. for 1 hour;

[0033] S5, after the mixture obtained in step S4 is cooled to room temperature, wash, dry and grind to obtain Ga 1.99 o 3 :0.01Cr 3+ Nano phosphor.

Embodiment 2

[0035] S1, choose Ga(NO 3 ) 3 , CrCl 3 , sodium hydroxide, sodium chloride, and water as raw materials, according to the phosphor chemical expression Ga 2-X o 3 :xCr 3+ The stoichiometric ratio of each chemical component in, weighed 1.6mmol Ga(NO 3 ) 3 , 0.4mmol CrCl 3 , 2mmol sodium hydroxide, 8mmol sodium chloride raw material mixing;

[0036] S2. Pour the mixture obtained in step S1 into 10 mL of water, grind for 15 minutes and mix well;

[0037] S3, vacuum drying the mixture obtained in step S2 for 20 minutes;

[0038] S4. Transfer the powder in step S3 to an alumina crucible, put it into a box furnace, and calcinate at 500° C. for 5 hours;

[0039] S5, after the mixture obtained in step S4 is cooled to room temperature, wash, dry and grind to obtain Ga 1.6 o 3 :0.4Cr 3 + Nano phosphor.

Embodiment 3

[0041] S1, choose GaCl 3 , Cr(NO 3 ) 3 , Potassium Hydroxide, Potassium Chloride, and Ethanol as raw materials, according to the chemical expression of phosphor powder Ga 2-X o 3 :xCr 3+The stoichiometric ratio of each chemical component in, weighed 1.55mmol Ga(NO 3 ) 3 , 0.45mmol CrCl 3 , 1.5mmol potassium hydroxide, 10mmol potassium chloride raw materials are mixed;

[0042] S2. Pour the mixture obtained in step S1 into 10 mL of ethanol, grind for 20 minutes and mix well;

[0043] S3, vacuum drying the mixture obtained in step S2 for 15 minutes;

[0044] S4. Transfer the powder in step S3 to an alumina crucible, put it into a box furnace, and calcinate at 300° C. for 3 hours;

[0045] S5, after the mixture obtained in step S4 is cooled to room temperature, wash, dry and grind to obtain Ga 1.55 o 3 :0.45Cr 3+ Nano phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com