Method for making ultrafine fineness cocoon silk

A production method and fineness technology, which is applied in silk reeling, fiber treatment, silk fiber production, etc., can solve problems such as difficulty in obtaining silk fiber and development and application restrictions of ultra-fine fineness cocoon silk, so as to shorten the period of silkworm rearing and reduce the incidence of disease Ratio, denier difference effect is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. The Sanmian silkworm variety "SG×54A" (a breed bred by the Institute of Sericulture, Chinese Academy of Agricultural Sciences, Wu Yangchun, etc., Jiangsu Sericulture, 2004, Phase 1) was fed with fresh ripe mulberry leaves or artificial feed at 26 Raise silkworms until the second instar under the environment of -28°C;

[0027] 2, SM-I or golden deer three sleeping element (Li Rongqi etc., sericulture science, 1987,13 (2)) are mixed with sterile water (cold boiled water) the aqueous solution that concentration is 200ppm-1800ppm; The prepared aqueous solution is evenly sprayed on the front and back sides of mulberry leaves, dried in the shade and cut into an area of 2.5cm 2 the leaves;

[0028] 3. Continuously feed the leaves sprayed with SM-I or Sanmiansu aqueous solution to the second instar silkworms of the Sanmian silkworm variety for 24 hours; the test found that 200ppm-1800ppm of Sanmiansu aqueous solution can induce the change of Sanmian silkworm It is Dimian...

Embodiment 2

[0031] 1. The Sanmian silkworm variety "SG×54A" (a breed bred by the Institute of Sericulture, Chinese Academy of Agricultural Sciences, Wu Yangchun, etc., Jiangsu Sericulture, 2004, Phase 1) was fed with fresh ripe mulberry leaves or artificial feed at 26 The silkworms were reared at -28°C until the third instar.

[0032]2, SM-I or golden deer three sleeping element (Li Rongqi etc., sericulture science, 1987,13 (2)) are mixed with sterile water (cold boiled water) the aqueous solution that concentration is 200ppm-1800ppm; The prepared aqueous solution is evenly sprayed on the front and back sides of mulberry leaves, dried in the shade and cut into an area of 4cm 2 the leaves;

[0033] 3. The leaves sprayed with the superfine element aqueous solution were continuously fed to the third instar silkworms of the three-drown silkworm variety for 24 hours; it was found that 200ppm-1800ppm of the ultrafine element aqueous solution could induce the three-drown silkworms to become t...

Embodiment 3

[0036] 1. The Sanmian silkworm variety "853bai X543B" (a breed bred by the Sericulture Research Institute of the Chinese Academy of Agricultural Sciences, Wu Yangchun, etc., Jiangsu Sericulture, 2004, the first phase) was fed with fresh and ripe mulberry leaves or artificial feed at 26 Raise silkworms until the second instar under the environment of -28°C;

[0037] 2. Prepare SM-1 (Li Rongqi et al., Sericulture Science, 1987, 13(2)) with sterile water (cold boiled water) to make an aqueous solution with a concentration of 200ppm-1800ppm. Spray evenly on the front and back sides of mulberry leaves with an ultra-fine sprayer, dry in the shade and cut into 2.5cm areas 2 the leaves;

[0038] 3. The leaves sprayed with the SM-1 aqueous solution were continuously fed to the second-instar silkworms of the three-dormant silkworm variety for 24 hours. It is found that the aqueous solution with a concentration of 200ppm-1800ppm can induce three-drown silkworms to change into two-drown...

PUM

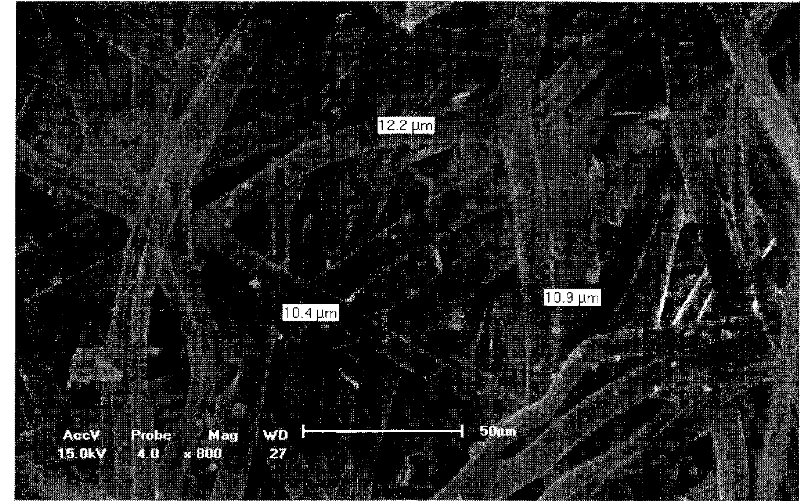

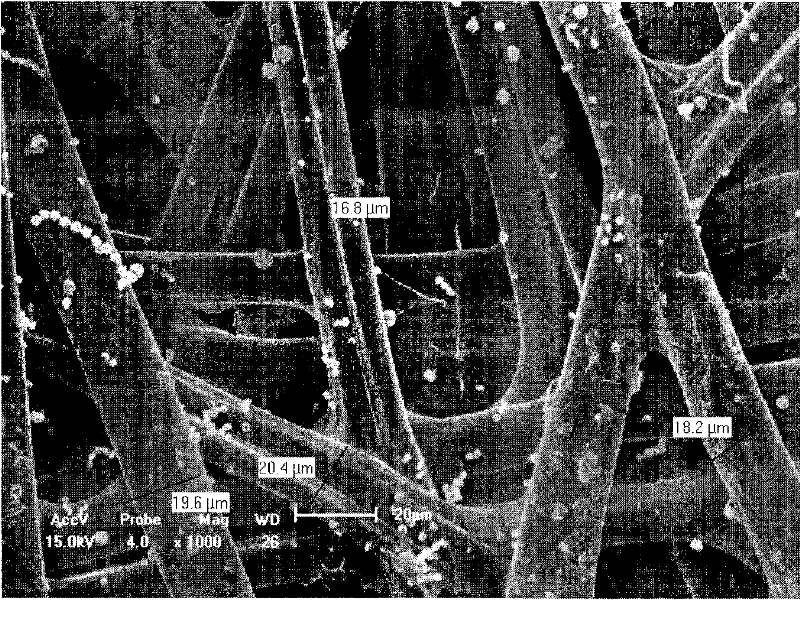

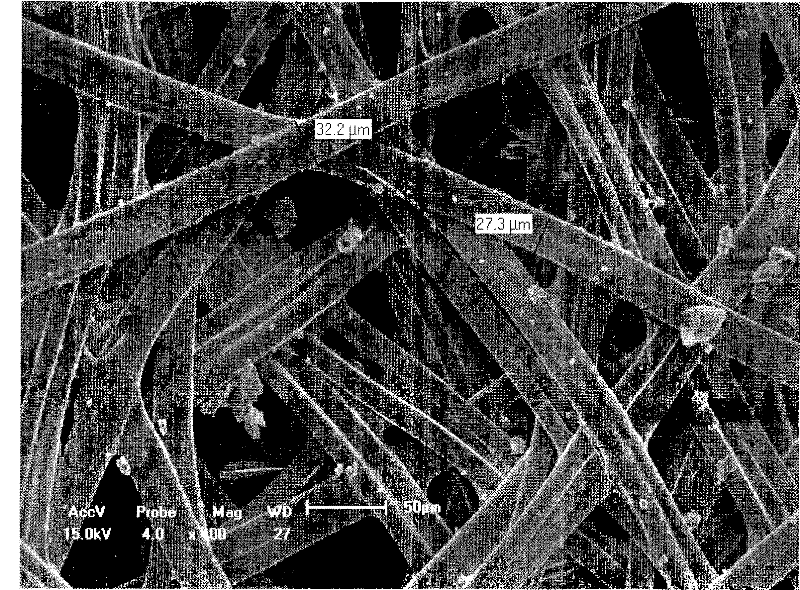

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com