Method for preparing ethanol by using raw material containing manioc waste

A technology of cassava residues and raw materials, which is applied in the direction of using microorganisms, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of low utilization rate of cassava residues, low ethanol yield, etc., so as to improve the utilization rate, Effect of improving sugar conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This example is used to illustrate the method of the present invention for producing ethanol using raw materials containing cassava residues.

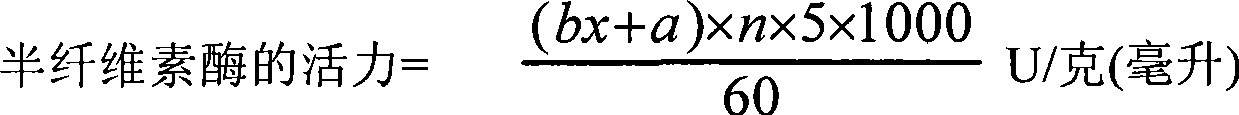

[0060] (1) Determination of the total weight of cellulose and the total weight of hemicellulose in raw materials containing cassava residues:

[0061] 3000 grams of waste cassava residues (water content: 10%) after fermenting ethanol were crushed to a particle diameter of 3 mm, 5 grams of which were dried at 45°C to a constant weight of 4 grams, and 300.0 mg of the cassava was weighed. The dried cassava residue is placed in a 100 milliliter dry conical flask weighing 80 grams. Add 3.00 ml of sulfuric acid solution with a concentration of 72% by weight into the Erlenmeyer flask, and stir for 1 minute. The Erlenmeyer flask was then placed in a water bath at 30 °C for 60 minutes, stirring every 5 minutes to ensure uniform hydrolysis. After the hydrolysis, the concentration of sulfuric acid was diluted to 4% by weight with deioniz...

Embodiment 2

[0073] This example is used to illustrate the method of the present invention for producing ethanol using raw materials containing cassava residues.

[0074] Prepare ethanol according to the method of Example 1, the difference is that in the enzymolysis step, the cassava residues are mixed with the enzyme in three batches, and the amount of the cassava residues added in the first batch is 60% of the weight of all the remaining cassava residues after the sampling test %, heat and mix at 50°C for 100 minutes; then add the second batch of cassava residues, the amount of the second batch of cassava residues added is 20% of the weight of all remaining cassava residues after sampling and testing, and heat and mix at 50°C for 50 minutes Then add the third batch of cassava residues, the amount of the third batch of cassava residues added is 20% of the weight of the remaining whole cassava residues after the sampling test, and obtain the enzymolysis product after 42 hours of insulated e...

Embodiment 3

[0076] This example is used to illustrate the method of the present invention for producing ethanol using raw materials containing cassava residues.

[0077] Prepare ethanol according to the method of Example 1, the difference is that in the enzymolysis step, the cassava residues are mixed with the enzyme in three batches, and the amount of the cassava residues added in the first batch is 20% of the weight of all the remaining cassava residues after the sampling test %, insulated and mixed at 52°C for 20 minutes; then added the second batch of cassava residues, the amount of the second batch of cassava residues added was 40% of the weight of all the remaining cassava residues after the sampling test, and mixed at 52°C for 40 minutes Then add the third batch of cassava residues, the amount of the third batch of cassava residues added is 40% of the weight of the remaining whole cassava residues after the sampling test, and obtain the enzymatic hydrolysis product after 42 hours of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com