Die quenching machine tool for numerical control force measurement

A technology of mold press quenching and machine tools, which is applied in quenching devices, heat treatment equipment, manufacturing tools, etc., to achieve the effect of meeting the oil entry time, avoiding erosion and pollution, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

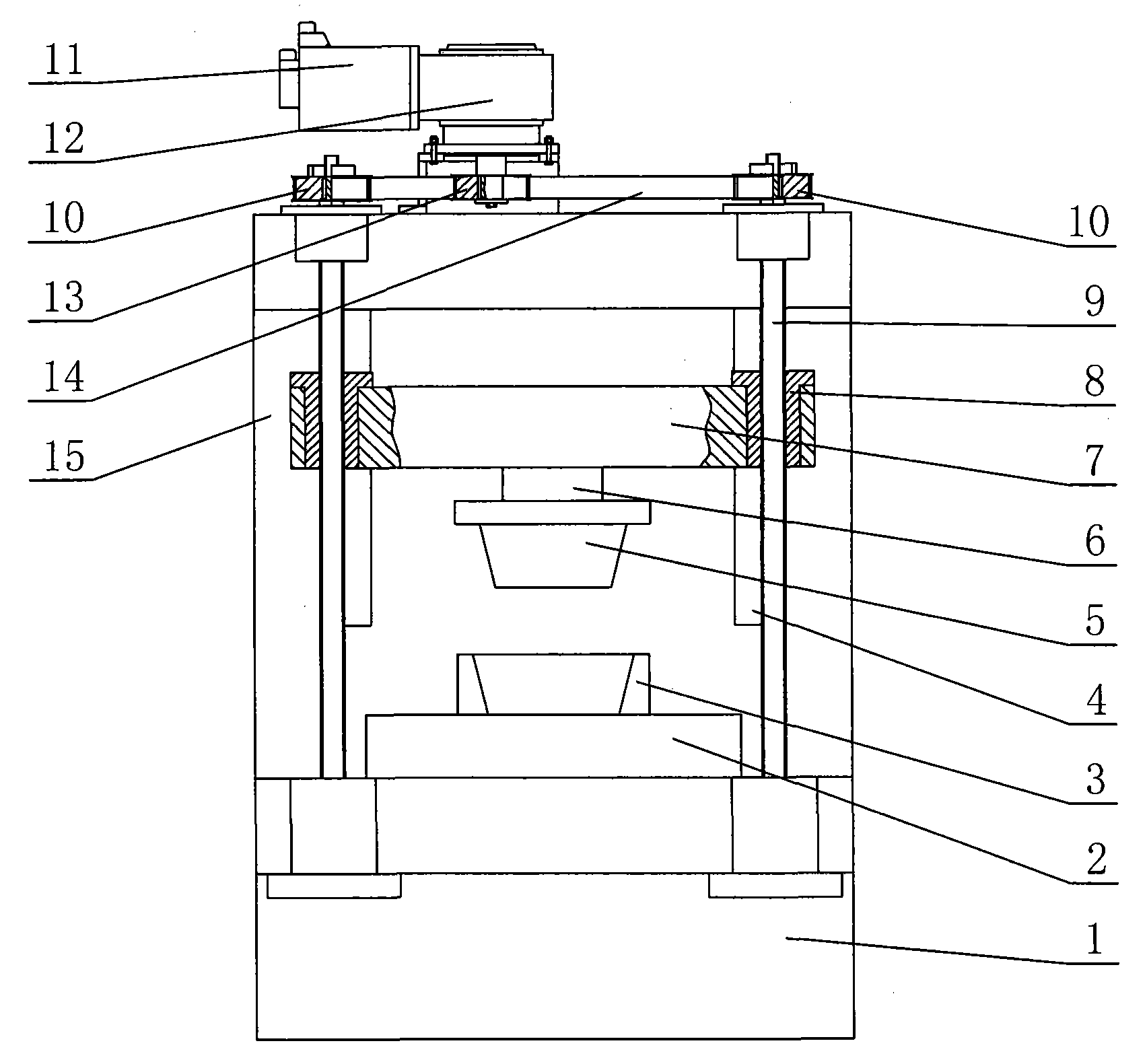

[0026] As shown in Figure 1, the quenching machine tool is a "door"-shaped double screw dragging quenching machine tool. The workbench 2 is installed on the base 1, and the lower mold 3 for fixing the workpiece to be quenched is installed on the workbench, and the upper mold 5 for fixing the workpiece to be quenched is installed on the moving beam 7 through the load cell 6, and the moving beam 7 Can move up and down along the vertical guide rail 4 on the lathe bed 15. A servo motor and a rotary encoder group 11 are installed on the upper part of the bed 15. The servo motor drives the reducer 12 to rotate. The toothed belt pulley 10 rotates, and the upper end of two passive toothed belt pulleys 10 and the ball screw 9 in the ball screw pair is connected by a key, and two nuts 8 in the ball screw pair are fixed on the left and right ends of the moving beam. When quenching, the workpiece to be quenched is installed in the lower mold. At this time, the servo motor-reducer-toothed...

Embodiment 2

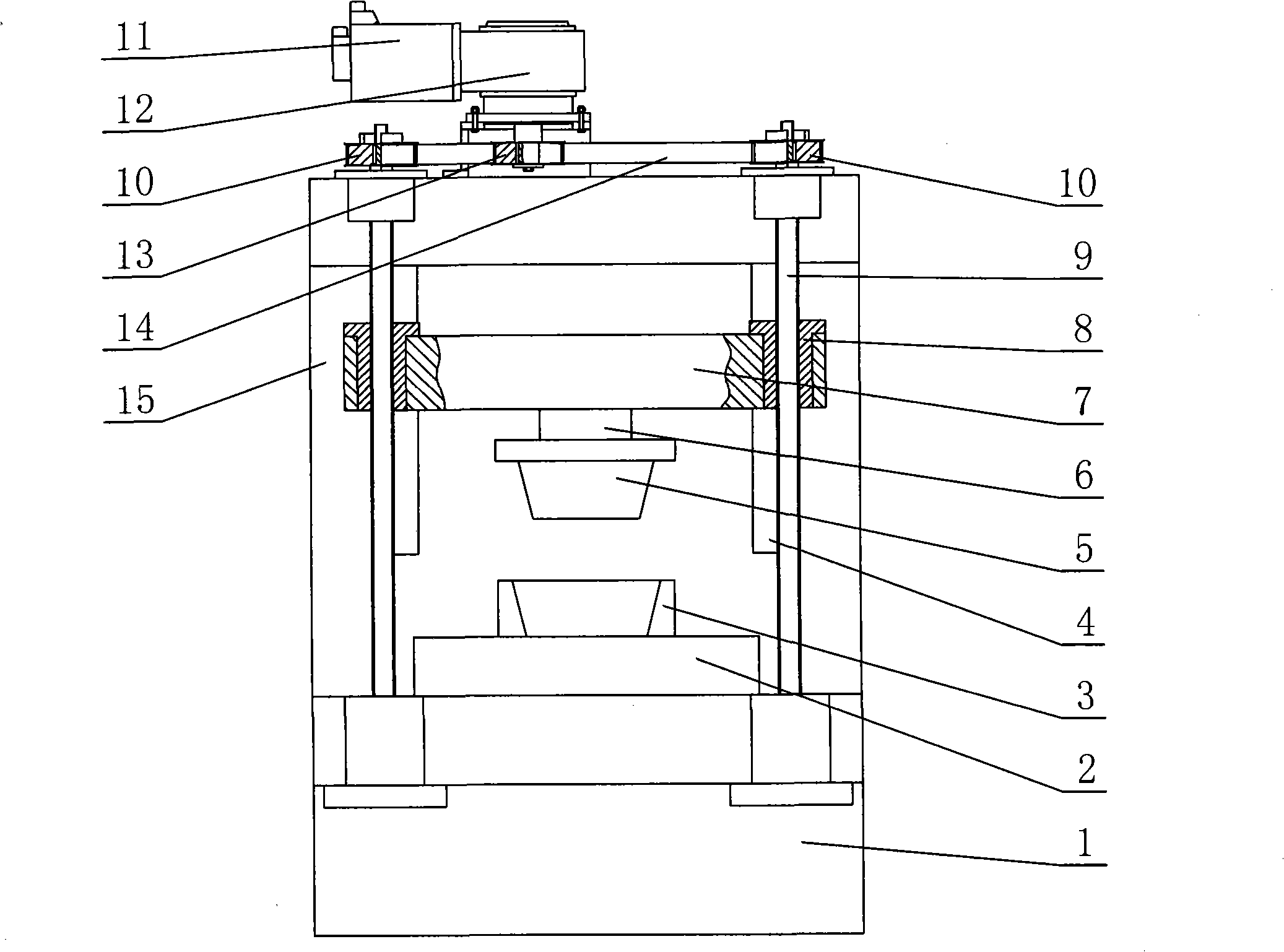

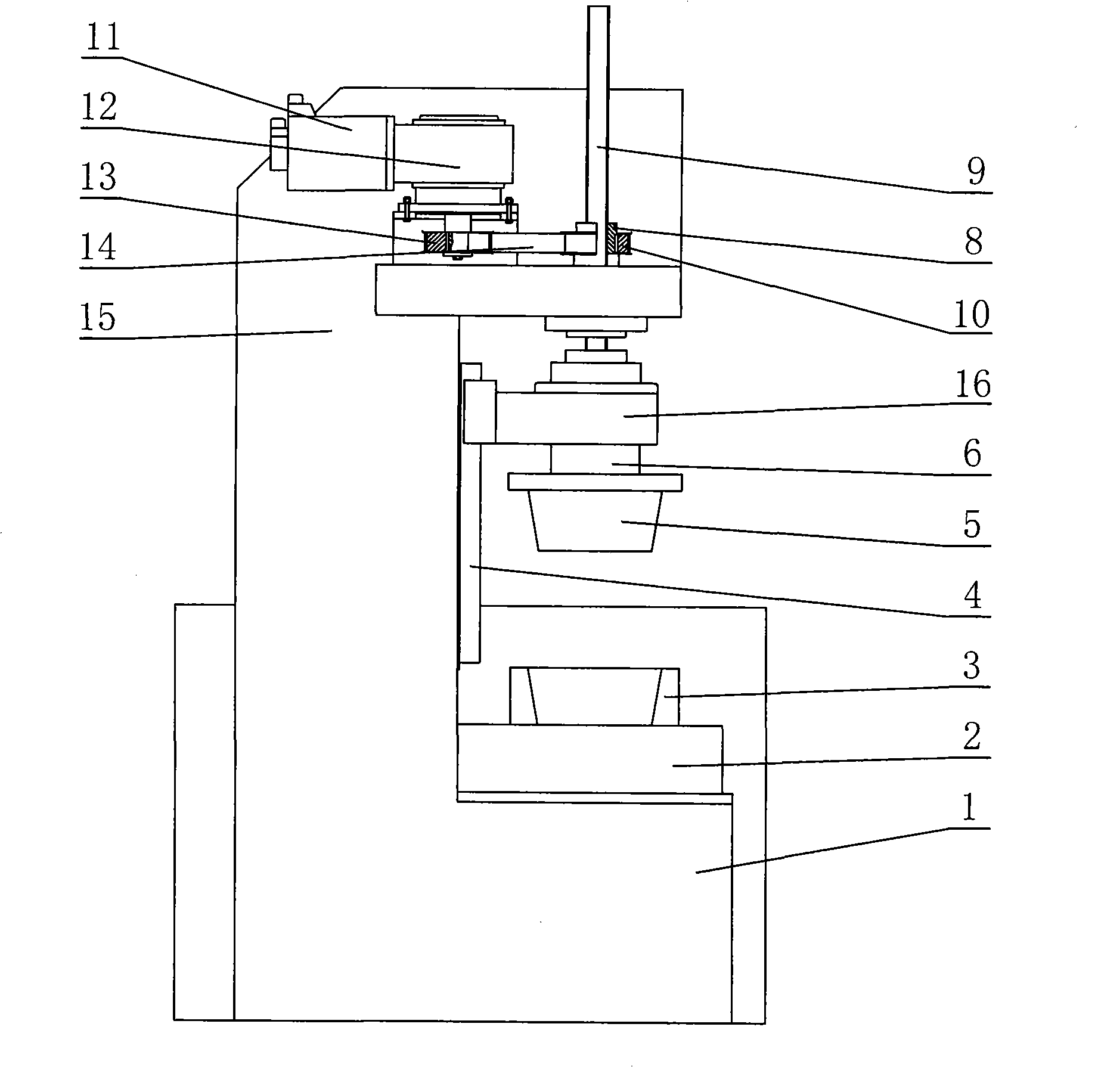

[0028] What this embodiment is aimed at is the quenching machine tool of " C " shape fuselage. As shown in Figure 2, the workbench 2 is installed on the base 1, and the lower mold 3 for fixing the workpiece to be quenched is installed on the workbench 2, and the upper mold 5 for fixing the workpiece to be quenched is installed on the slider through a load cell 6 16, the slide block 16 can move up and down along the vertical guide rail 4 on the machine bed 15. A servo motor and a rotary encoder group 11 are installed on the upper part of the bed 15. The servo motor drives the reducer 12 to rotate. The toothed pulley 10 rotates, and the nut 8 is coaxially installed on the driven toothed pulley 10. Since the nut 8 is axially fixed and can only rotate, the ball screw 9 moves up and down under the drive of the nut, and the lower end of the ball screw is rotatably connected with the slide block 16 . The transmission line during quenching is: servo motor-reducer-active toothed belt...

Embodiment 3

[0030] On the basis of Embodiment 1, the rotation of the ball screw is changed to the rotation of the nut, and the transmission of movement and force is changed from a double ball screw pair to a single ball screw pair, and the driven toothed pulley 10 is coaxially installed On the nut 8 in the ball screw pair, the lower end of the ball screw 9 is rotatably connected to the moving beam 7, and the rest of the structures remain unchanged.

[0031] In the above embodiments, the force sensor 6 can be a tension and pressure sensor.

[0032] The control system adopts computer control, which has the functions of timely data collection, digital display, storage, printing and network communication, and the quenching pressure of the whole quenching process is controlled by closed loop to control the corresponding relationship between the pressure and time applied to the quenched workpiece. Make the quenched workpiece always follow the designed quenching process curve during the quenchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com