TFT-LCD pixel structure and method for manufacturing same

A technology of pixel structure and manufacturing method, used in semiconductor/solid-state device manufacturing, instruments, semiconductor devices, etc., can solve the problems of large area and wide distribution of rubbing alignment shadow area, and avoid bad defects, distribution concentration, and liquid crystal alignment quality. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

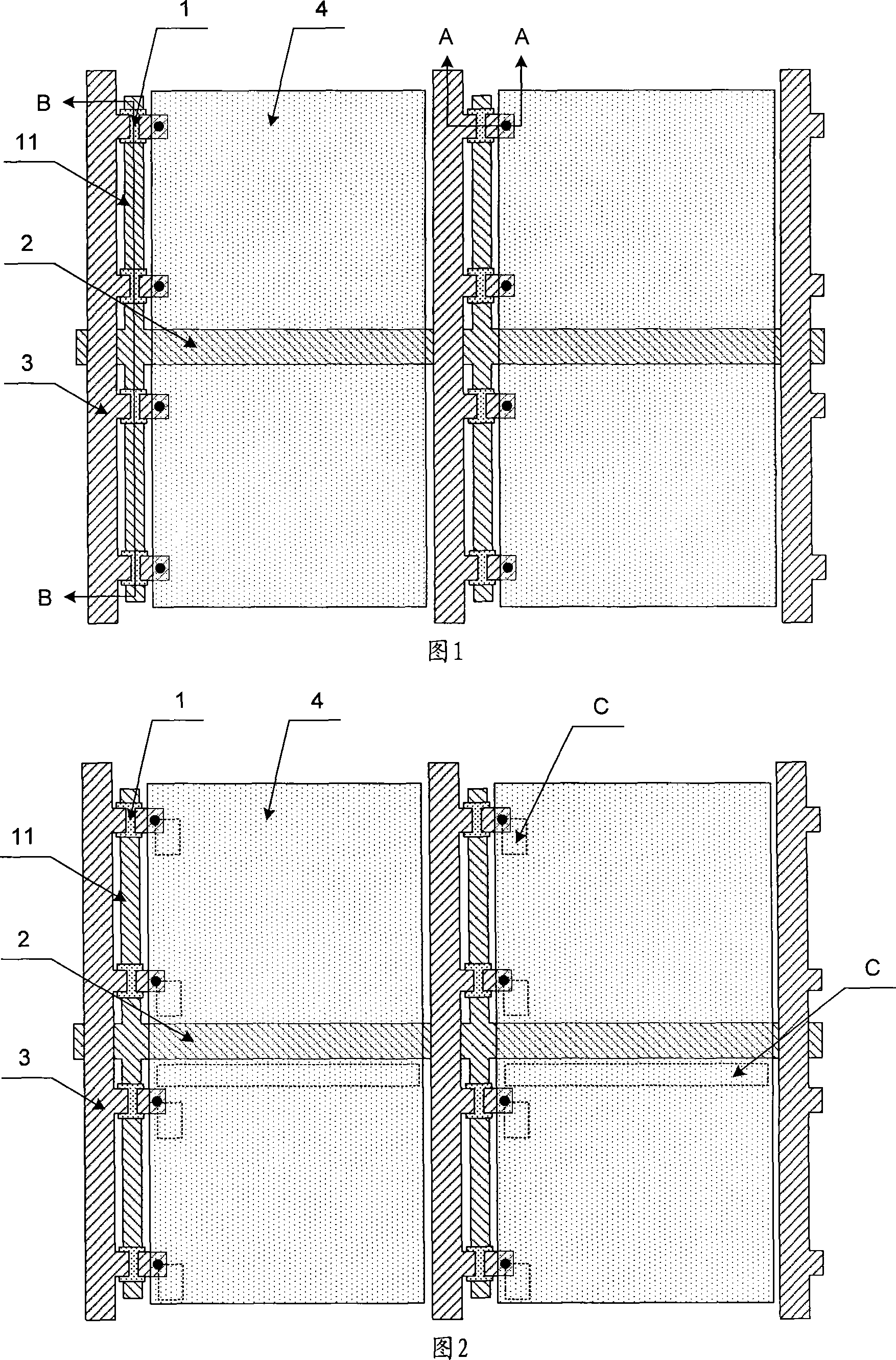

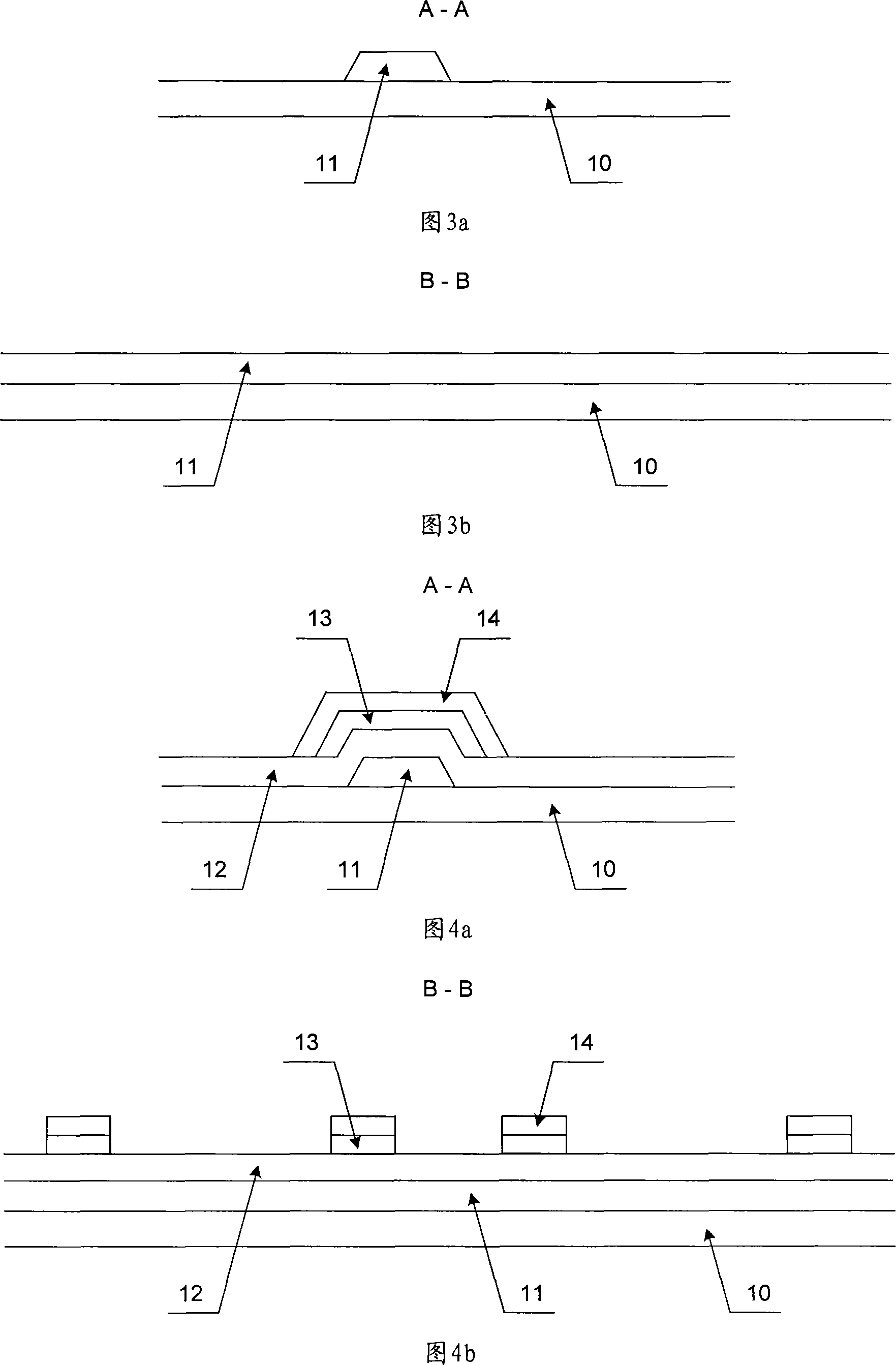

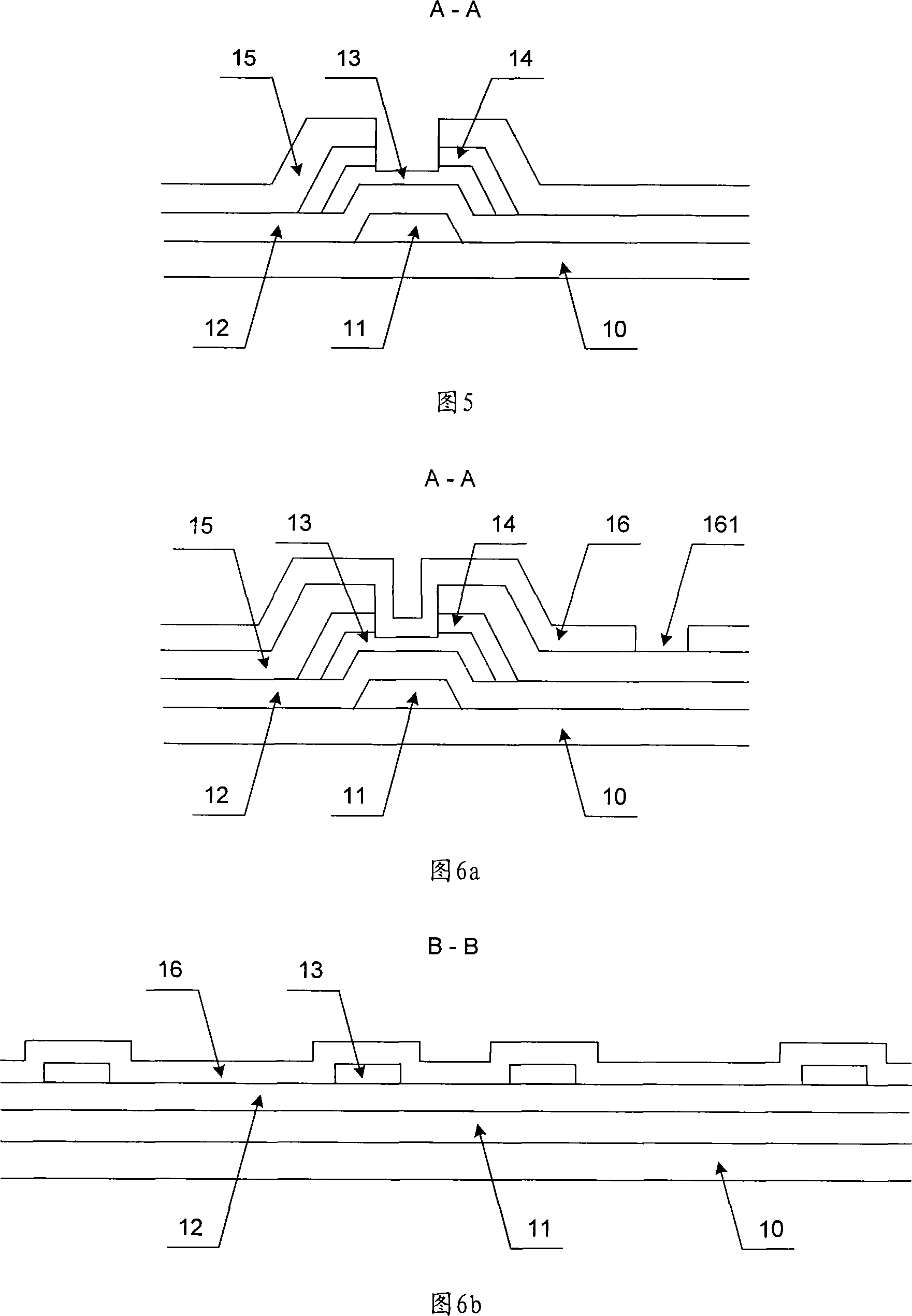

[0047] figure 1 It is a structural schematic diagram of the first embodiment of the TFT-LCD pixel structure of the present invention. Such as figure 1 As shown, the TFT-LCD pixel structure of this embodiment includes a thin film transistor 1, a gate line 2, a data line 3 and a pixel electrode 4, wherein the gate line 2 is arranged horizontally and is located in the middle of the pixel area, and the data line 3 is perpendicular to the gate line 2 set, and located outside the pixel area (such as figure 1 on the left side of the pixel area), several thin film transistors 1 are arranged outside the pixel area (such as figure 1The left side of the gate line) is connected to the pixel electrode 4 formed in the pixel area, and the overlapping part of the pixel electrode 4 and the gate line 2 forms a storage capacitor. Specifically, several thin film transistors 1 are arranged on the gate electrode line 11 outside the pixel area, and the gate electrode line 11 is vertically arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com