Isolative double cooling electric surge tolerant resistor cabinet

A resistance cabinet and electric resistance technology, which is applied in the direction of resistors, resistor parts, spiral coil/screw disk resistance elements, etc., can solve the problems of volume increase, safety hazards, volume reduction, etc., and achieve simple and compact structure, occupying small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

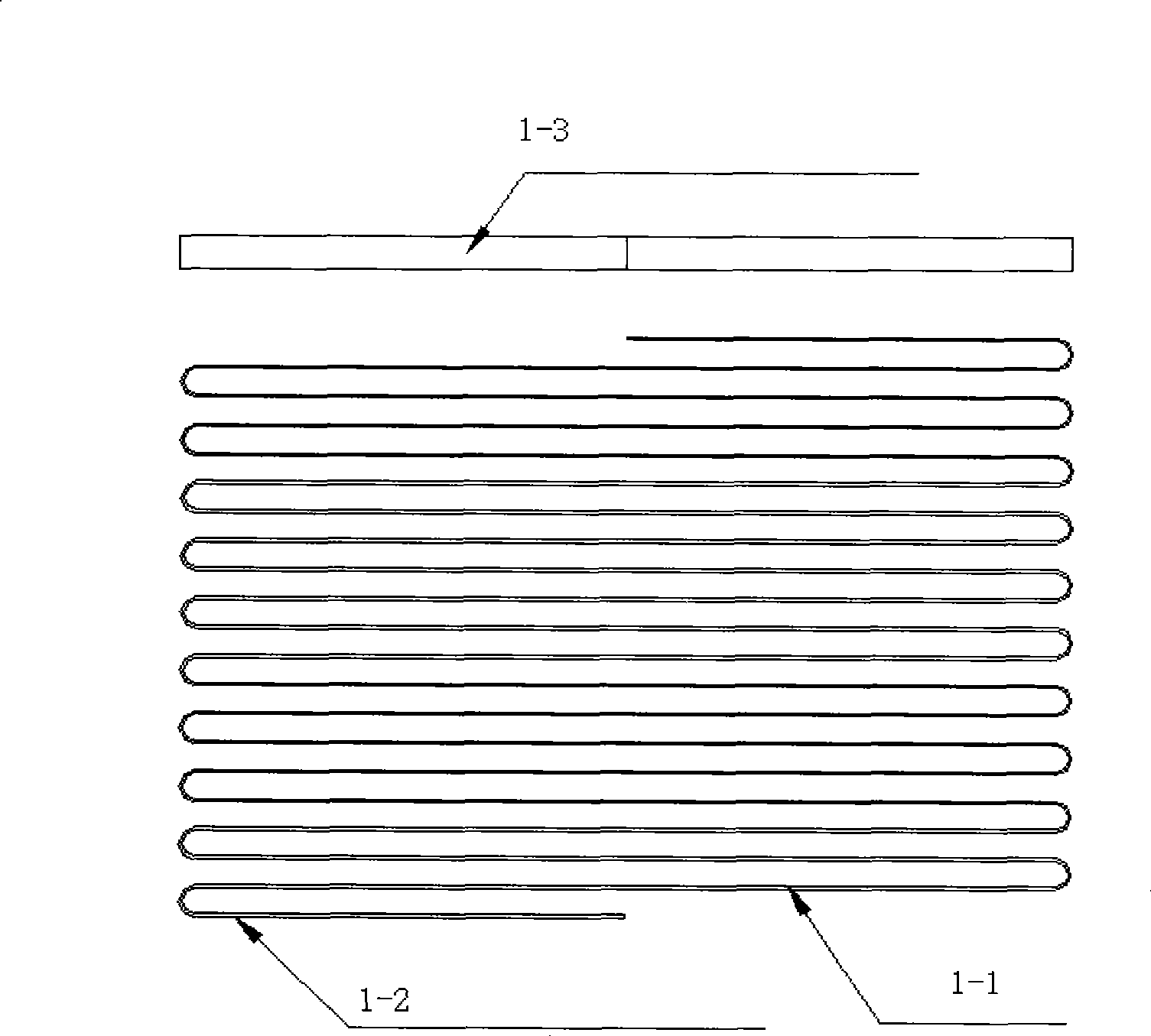

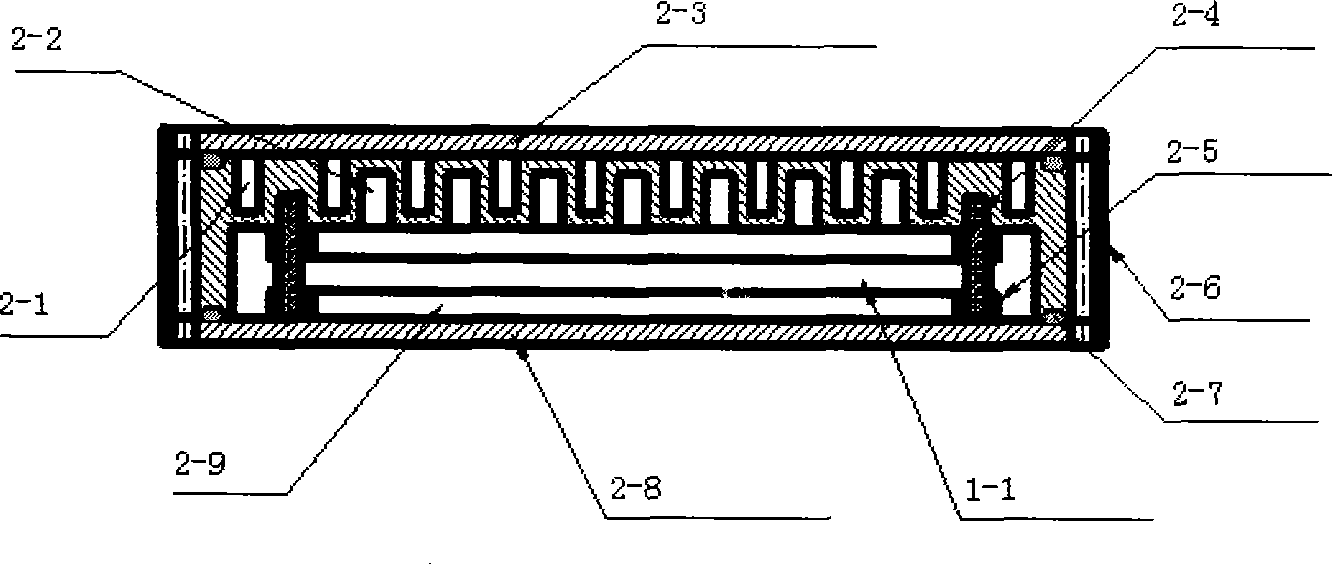

[0038] exist Figure II in, will 1-1 resistance core pass 2-4 insulating posts , 2-5 insulation ring fixed at 2-6 double cold boxes of 2-9 oil cavity inside, will 1-1 Resistor core and Figure three middle 3-1 electrode connect, cover 2-3 sink sealing plate and 2-8 oil tank sealing plate , assembled into Insulated double cold resistance Surge resistance box .

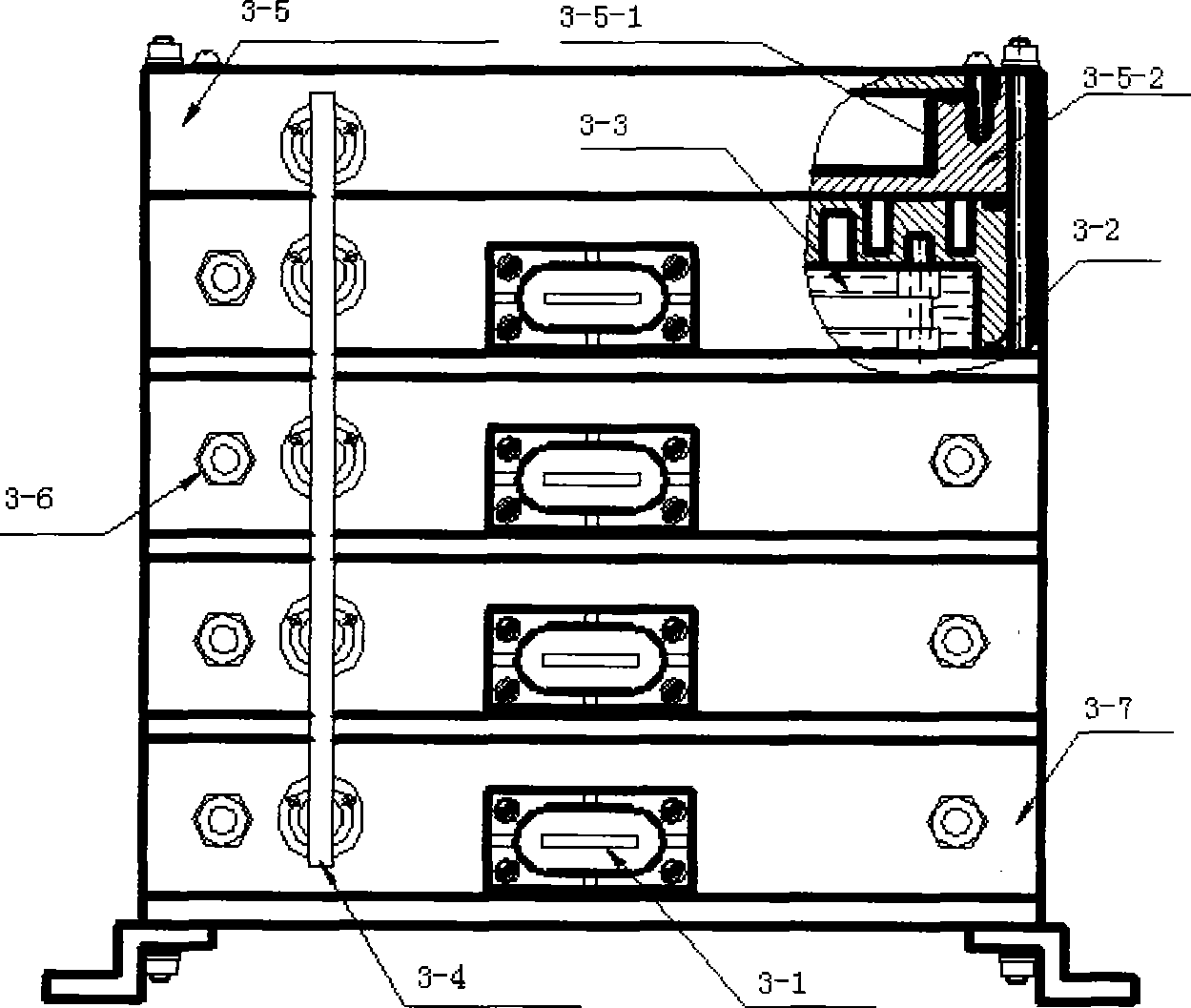

[0039] exist Figure three In, multiple groups Insulated double cold surge resistance box Stacked installation, and installed on top 3-5 half capsule oil storage tank , fixed with bolts, with 3-4 pressure relief pipe multiple Insulated double cold surge resistance box and 3-5 half capsule oil storage tank The oil circuit is connected. The external waterway and electric circuit just can work.

[0040] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Any person skilled in the art within the tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com