Voltage orienting frequency conversion controller for open loop non-speed sensor

A technology without speed sensor and frequency conversion controller, which is applied in the direction of electronic commutation motor control, motor generator control, electromechanical brake control, etc., can solve the problems of poor load capacity of the motor, light-load oscillation, etc., and achieve stable operation and low cost. Low, the effect of suppressing light load oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

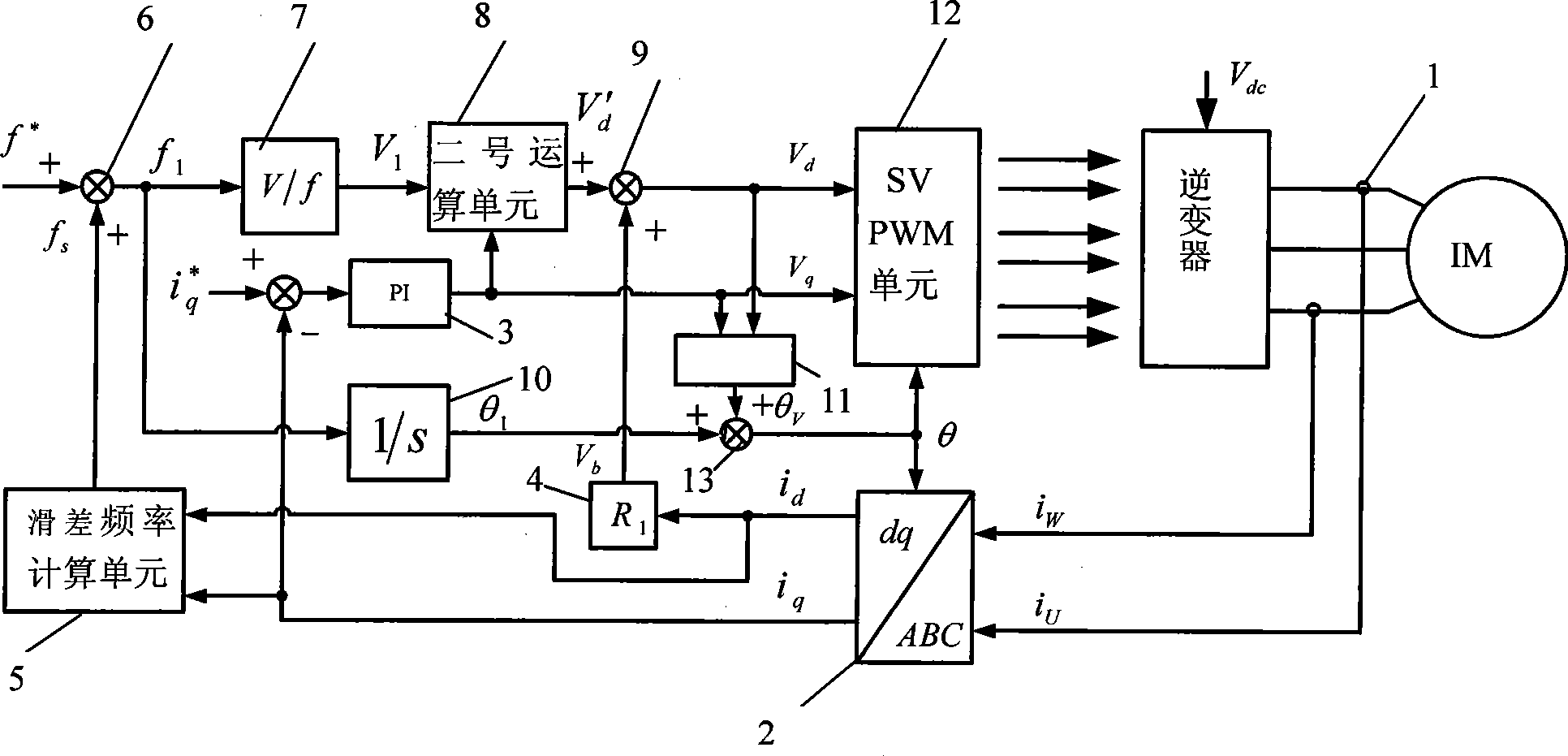

[0023] Specific implementation mode one: the following combination Figure 1 to Figure 3 This embodiment will be specifically described. The controller of the present invention is made up of the following units;

[0024] Current sensor 1: to detect the phase current on the stator of the induction motor IM through the current sensor 1;

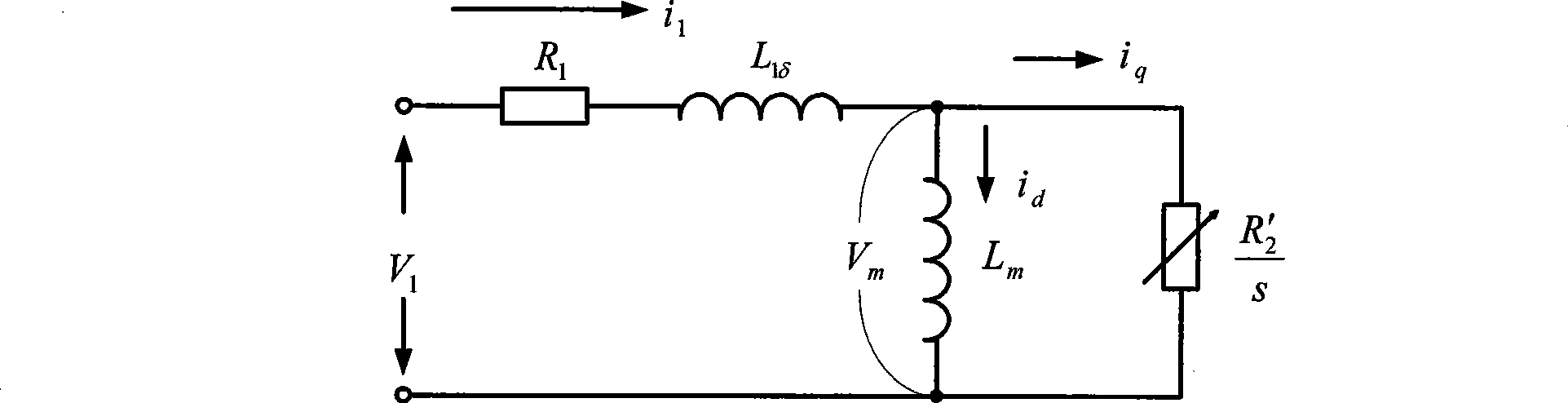

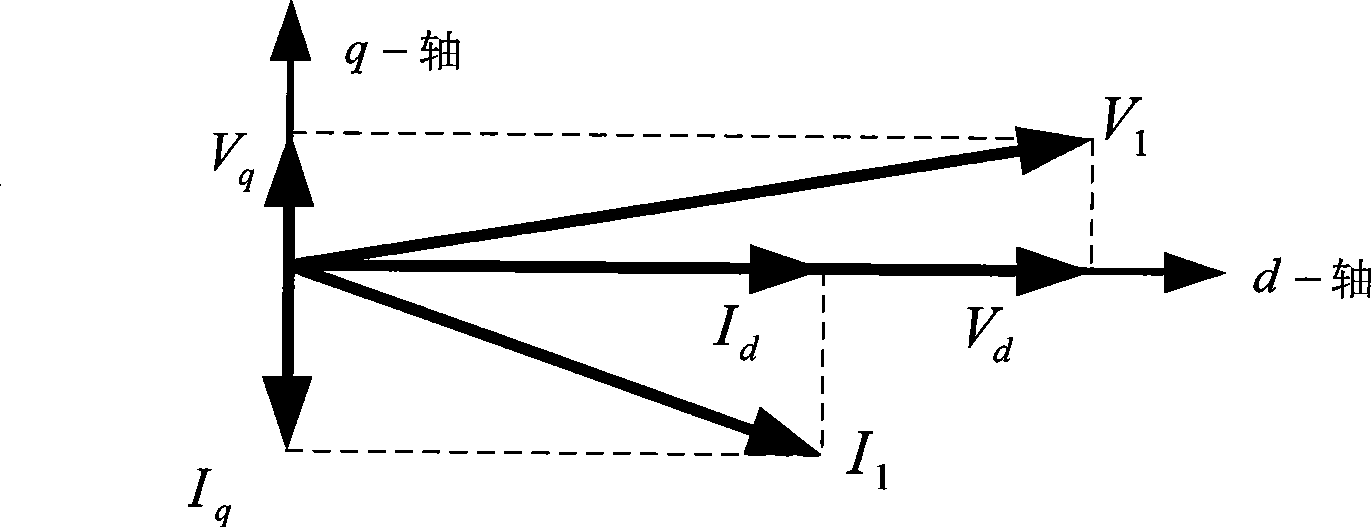

[0025] Vector coordinate transformation unit 2: to realize the directional coordinate transformation of the induction motor IM stator voltage, and decompose the detected stator current into instantaneous active current i d and instantaneous reactive current i q ;

[0026] PI regulator 3: set the given reactive current i q * and instantaneous reactive current i q subtracted as the input of PI regulator 3, the output of the PI regulator V q As the q-axis voltage given value of SVPWM unit 12, to utilize PI regulator 3 to instantaneous reactive current i q Feedback control is performed so that the reactive current on the stator of the induc...

specific Embodiment approach 2

[0061] Specific implementation mode two: the following combination Figure 4 to Figure 9 A specific example is given. This embodiment adopts controller of the present invention and an inverter and an induction motor, and the parameter of this motor is as follows: rated voltage: 380V, rated current 15.4A, rated power is 7.5Kw, rated speed is 1440r / min, rated frequency It is 50Hz, the stator resistance is 0.611Ω, the rotor resistance is 0.434Ω, the excitation inductance is 105.6mH, and the stator leakage inductance is 2.32mH. Figure 4 It is the current waveform of the motor when it is no-load. From the figure, it can be seen that the motor current is stable and there is no oscillation phenomenon when it is no-load. Figure 5 It is the motor current waveform when starting with full load. It can be seen from the figure that the motor has a strong load capacity and quick response, and the current in the second cycle reaches a stable operating current. Image 6 It is the motor cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com