Brake disc having high temper softening resistance

A brake disc and tempering treatment technology, applied in the direction of brake discs, manufacturing tools, furnace types, etc., can solve the problems of reduced hardness, insufficient resistance to temper softening, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

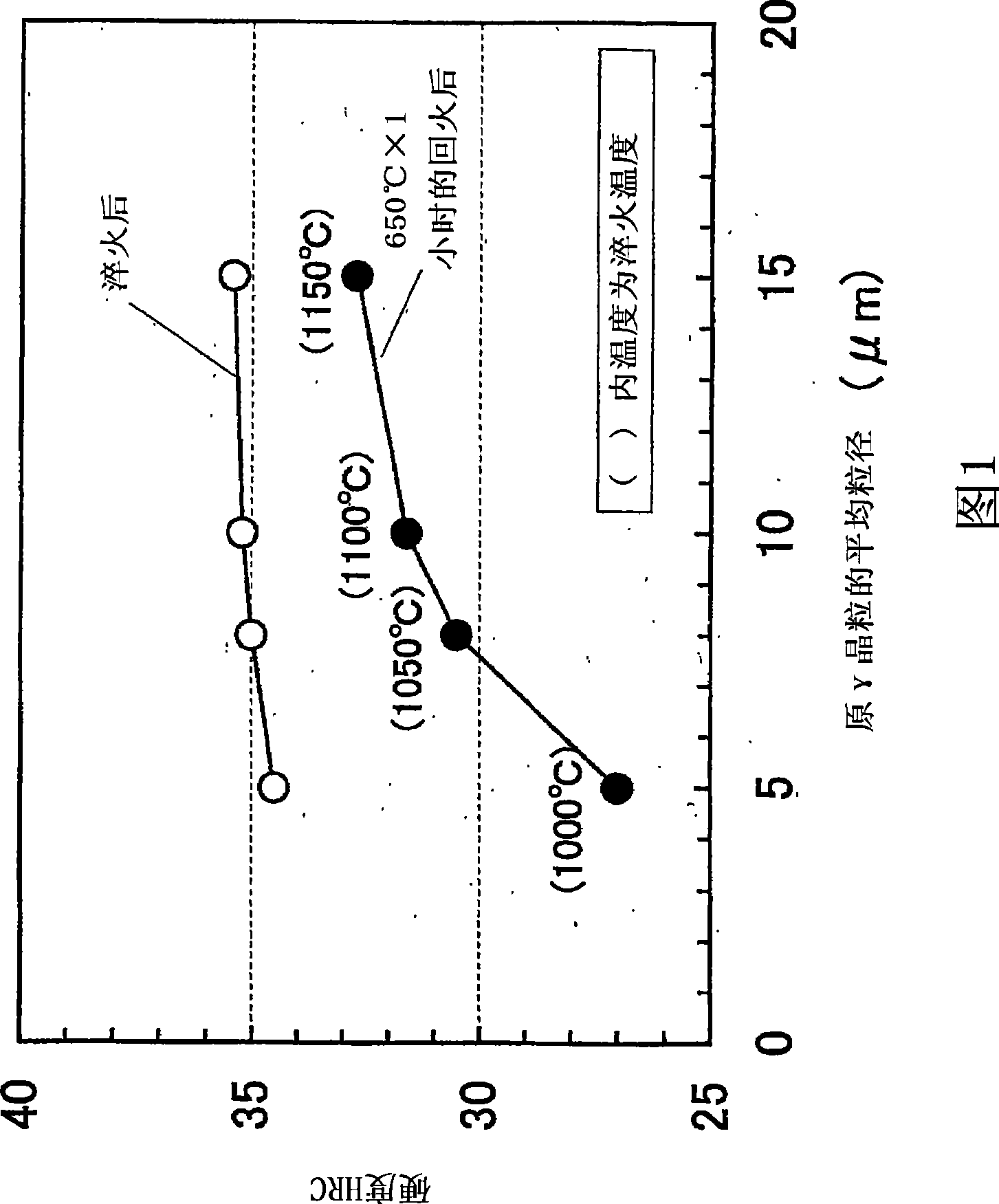

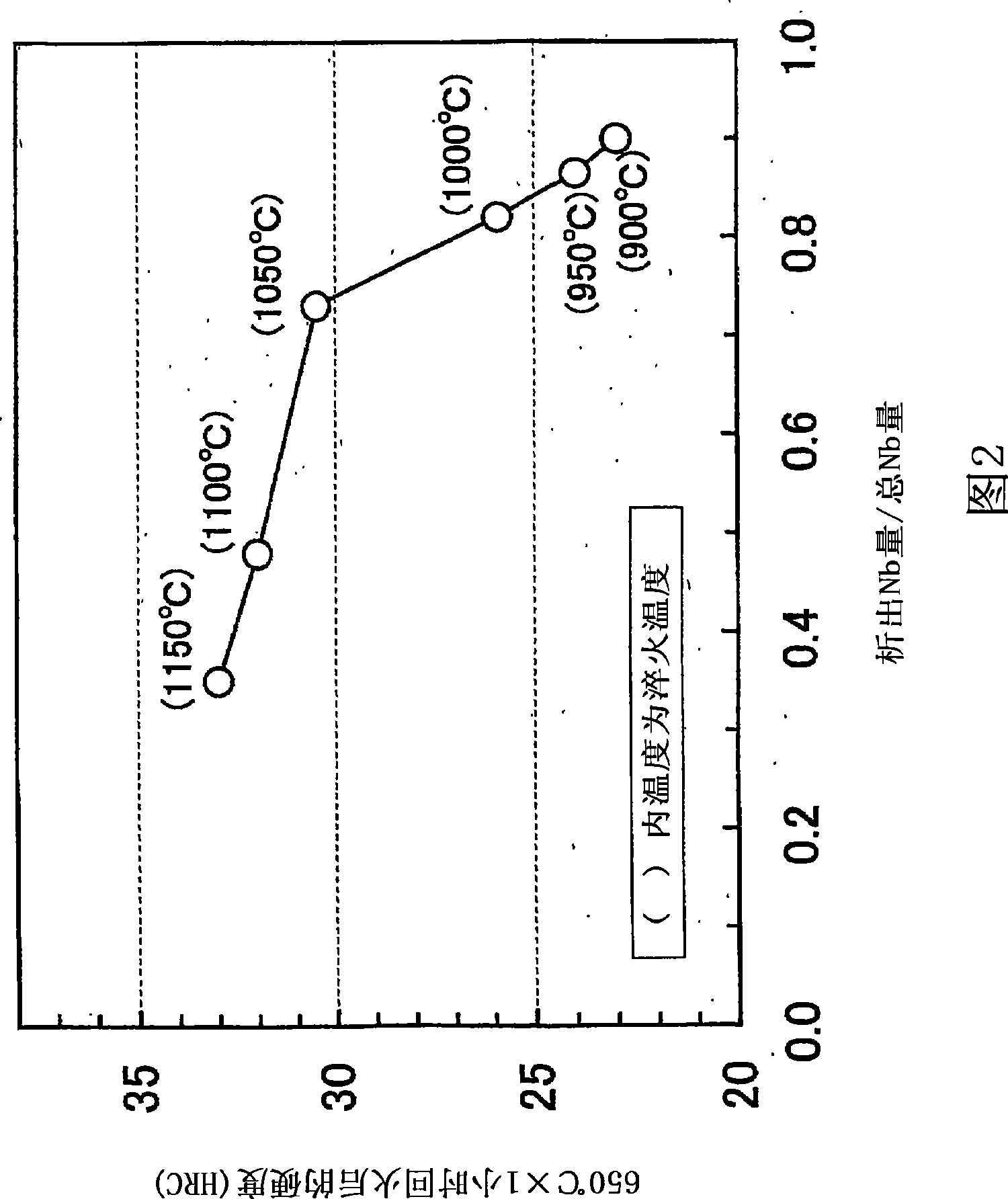

[0091] 19 kinds of martensitic stainless steels having different compositions of A to S shown in Table 1 were melted in a high-frequency melting furnace (high-frequency melting furnace), and cast into a 50 kg ingot, and then, under generally known conditions hot rolled steel sheets with a thickness of 5 mm, and then, these hot rolled steel sheets were annealed at 800°C for 8 hours in a reducing atmosphere, then cooled slowly, and removed by pickling. The scale on the surface is made of hot-rolled annealed sheet. From these hot-rolled annealed sheets, a test piece having a thickness of 30 mm×30 mm was taken, and the test piece was quenched under the conditions shown in Tables 2-1 to 3. For the quenched test piece, observation of the metal structure, measurement of the amount of precipitated Nb, quenching stability test, temper softening test, and measurement of the dislocation density after quenching and tempering were performed according to the following methods. In addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com