A plastic multi-principal laves-based intermetallic compound and its preparation method

A base metal and compound technology, applied in the field of multi-principal Laves-based intermetallic compounds and their preparation, can solve the problems of easy softening, poor Laves phase room temperature plasticity, low solid solution hardness, etc., and achieves good high temperature aging strengthening effect, good high temperature The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

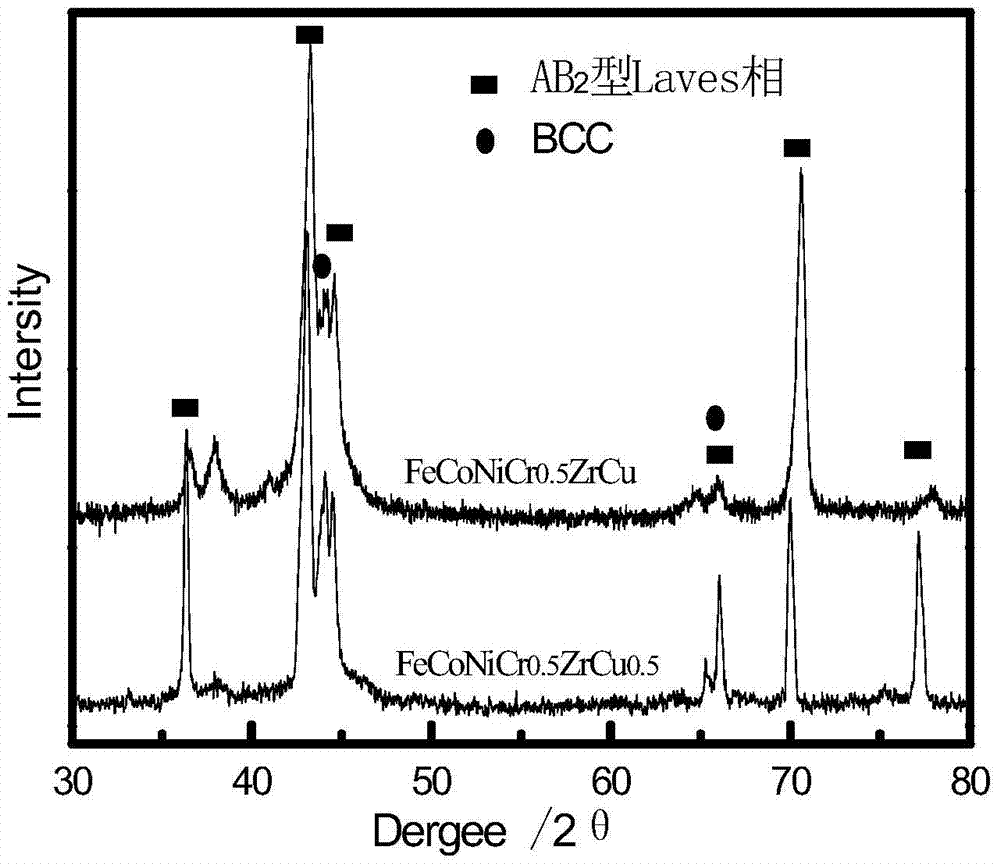

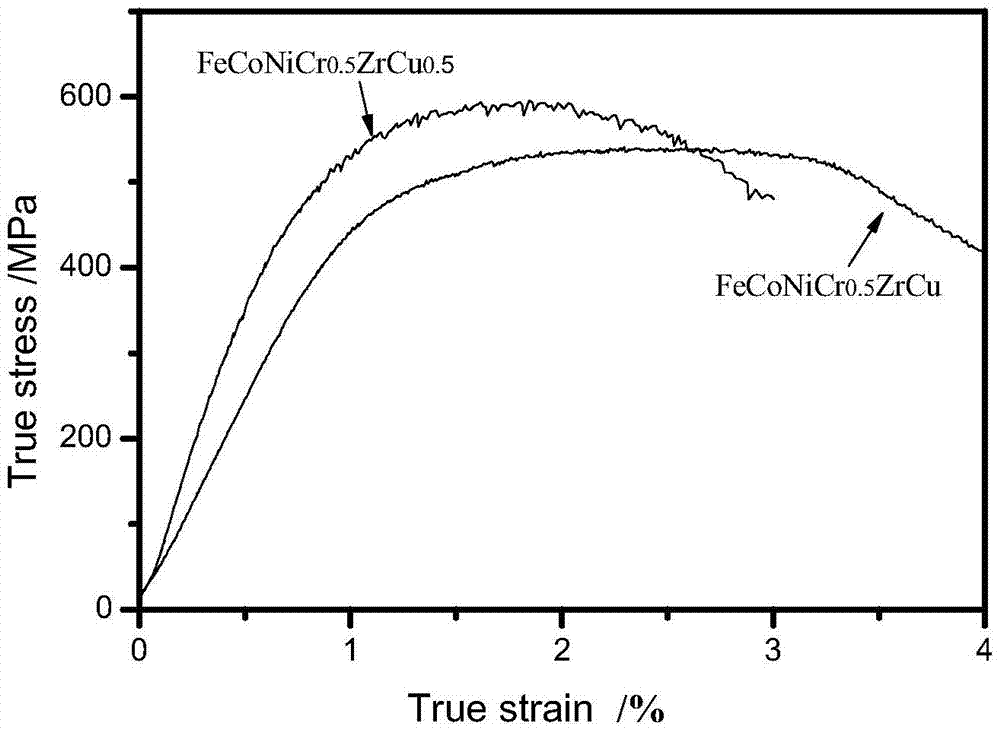

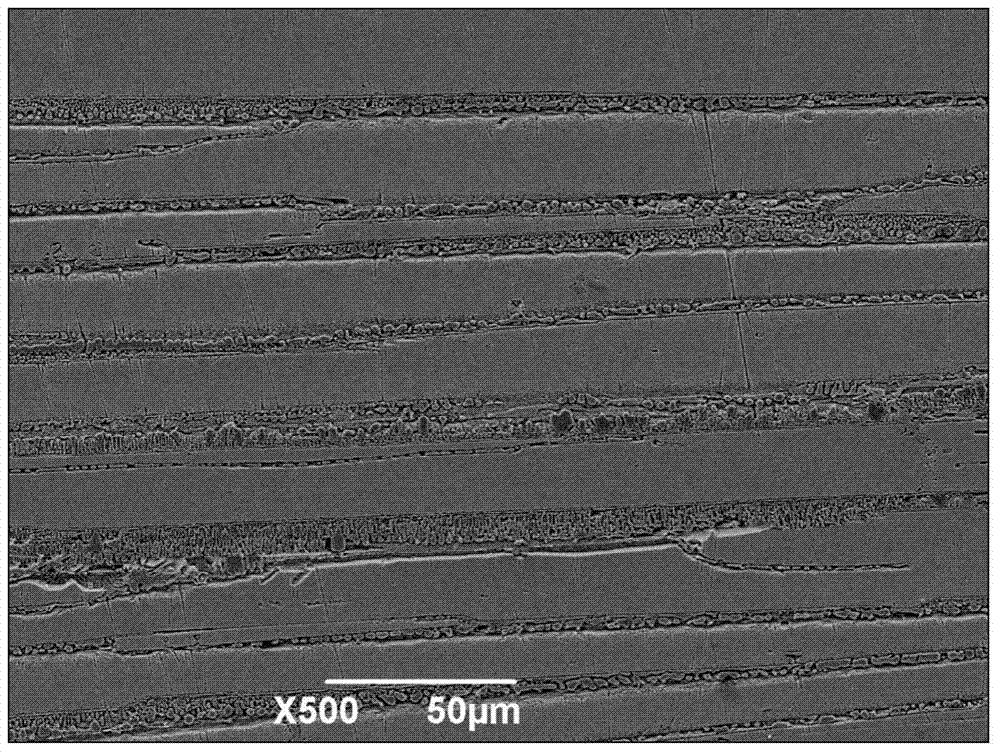

[0038] A plastic multi-principal Laves-based intermetallic compound whose main component is FeCoNiCr 0.5 ZrCu x , prefabricated two kinds of Laves-based intermetallic compounds in this embodiment, which are respectively denoted as FeCoNiCr 0.5 ZrCu 0.5 (Fe, Co, Ni, Cr, Zr and Cu molar ratio is 1:1:1::0.5:1:0.5), FeCoNiCr 0.5 ZrCu (Fe, Co, Ni, Cr, Zr and Cu molar ratio is 1:1:1::0.5:1:1), the intermetallic compound is prepared by electric arc furnace melting method, the selected Fe, Co, Ni, Cr, The purity of the Zr and Cu raw materials are all ≥ 99%. An appropriate amount of raw materials is taken from the base metal, and the oxide skin on the surface of the raw metal is removed by mechanical grinding, and then the two Laves-based intermetallic compounds in this embodiment are designed. The molar ratio is converted into a weight ratio, and the raw materials are weighed by an electronic balance with an induction capacity of 0.1 mg, and mixed uniformly. Subsequently, the mixe...

Embodiment 2

[0046] A plastic multi-principal Laves-based intermetallic compound whose main component is FeCoNiCr 0.5 ZrCu 0.75 (Fe, Co, Ni, Cr, Zr and Cu molar ratio is 1:1:1::0.5:1:0.75), prepared by medium frequency induction furnace smelting method, selected Fe, Co, Ni, Cr, Zr and Cu The purity of the raw materials is ≥99%. An appropriate amount of raw materials is taken from the base metal, and the oxide skin on the surface of the raw metal is removed by mechanical grinding, and then the two Laves-based intermetallic compounds in this example are converted by the designed molar ratio For the weight ratio, use an electronic balance with an induction capacity of 0.1 mg to weigh the raw materials and mix them evenly. Subsequently, the mixed raw materials were placed in the copper crucible in the WK non-consumable vacuum electric arc furnace developed by Shenyang Vacuum Technology Research Institute, and the furnace body was evacuated. When the vacuum degree reached 5×10 -3 Argon (high-...

Embodiment 3

[0049] Same as Example 1, the difference is: the melting current is set to 250±30A, and the melting time is 30s. After the melting is uniformly cooled, the alloy block is turned over and repeated for smelting, and this is repeated 8 times to ensure that all elements of the alloy are evenly smelted. Finally, vacuum suction casting equipment is used to cast the smelted raw materials into ingots solidified on water-cooled copper molds to obtain solidified samples. The solidified samples were respectively kept in a vacuum resistance furnace at 750°C, 950°C and 1050°C for 2 hours and then air-cooled. Subsequently, X-ray diffractometer, optical microscope, scanning electron microscope and microhardness tester are used to detect the metallographic phase and properties of the material. The XRD results show that the Laves phase diffraction peak intensity of the material prepared under the conditions of this example is significantly higher than that of the bcc solid solution phase, indic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com