Friction-resistant titanium alloy steam turbine vane and production method thereof

A steam turbine blade and titanium alloy technology, which is applied in mechanical equipment, blade support elements, engine elements, etc., can solve the problems of steam turbine blade damage, high temperature, steam turbine blade breakage, etc., to improve friction resistance and high temperature resistance. , Increase hardness and prevent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

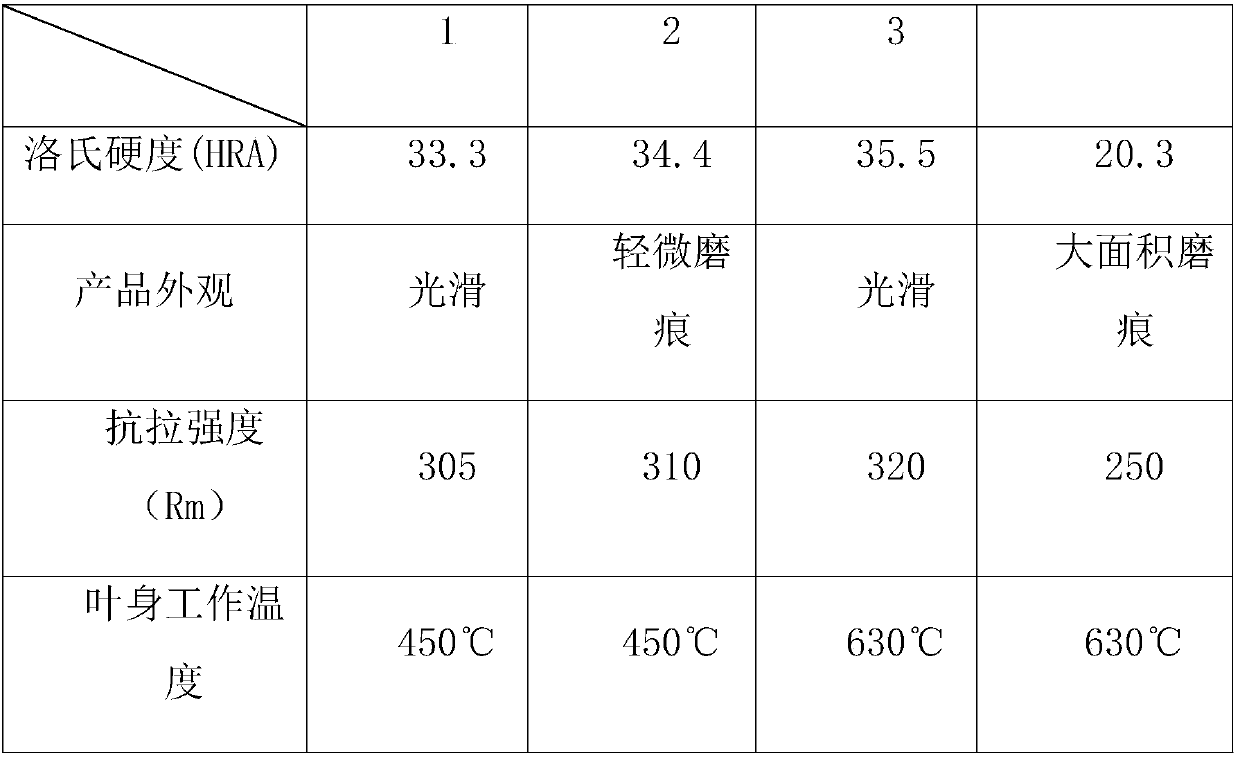

Embodiment 1

[0032] Embodiment 1: A friction-resistant titanium alloy steam turbine blade provided in this embodiment includes a blade root, a blade body and a blade crown, and the blade root, blade body and blade crown are fixedly connected in sequence, and the blade body includes an inner arc side and an outer arc side , the chemical composition and mass percentage content of the steam turbine blade are as follows:

[0033] The chemical composition and mass percentage content of the steam turbine blade are as follows:

[0034] C: 2.3%, Si: 0.1%, Mn: 0.3%, P: 0.01%, S: 0.01%, Ni: 0.2%, N: 2.2%, V: 0.2%, Ti: 0.14%, TiC: 0.15%, TiCN: 0.1%, ZrN: 0.1%, Cr: 1.2%, the total amount is 0.1% trace elements Cr and Co, the total amount is 0.01% β-NiAl intermetallic compound as the main phase alloy powder, and the balance is Fe .

[0035] A preparation method for a friction-resistant titanium alloy steam turbine blade, comprising the following steps:

[0036] a. Add C, Si, Mn, P, S, Ni, V, Ti, TiC...

Embodiment 2

[0052] Embodiment 2: A friction-resistant titanium alloy steam turbine blade provided in this embodiment includes a blade root, a blade body and a blade crown, and the blade root, blade body and blade crown are fixedly connected in sequence, and the blade body includes an inner arc side and an outer arc side , the chemical composition and mass percentage content of the steam turbine blade are as follows:

[0053] The chemical composition and mass percentage content of the steam turbine blade are as follows:

[0054] C: 3.2%, Si: 2.6%, Mn: 1.0%, P: 0.1%, S: 0.05%, Ni: 3.0%, N: 3.5%, V: 2.5%, Ti: 0.6%, TiC: 2.5%, TiCN: 1.9%, ZrN: 2.5%, Cr: 1.5%, the total amount is 0.5% trace elements Cr and Co, the total amount is 0.7% β-NiAl intermetallic compound as the main phase alloy powder, and the balance is Fe .

[0055] A preparation method for a friction-resistant titanium alloy steam turbine blade, comprising the following steps:

[0056] a. Add C, Si, Mn, P, S, Ni, V, Ti, TiC, Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com