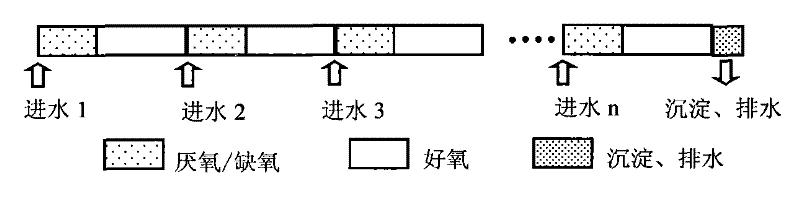

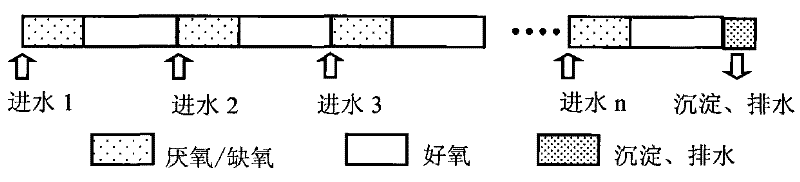

Method for Cultivating Granular Sludge in Anaerobic/Anoxic-Aerobic Sequencing Batch Reactor

A sequencing batch reactor and granular sludge technology, which is applied in the field of wastewater biological treatment, can solve the problems of high risk of failure, disintegration of granular sludge, etc., and achieve the effect of improving the settling performance and increasing the biological denitrification efficiency of the reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The residual sludge from the secondary settling tank of Waseca domestic sewage treatment plant (A / O biological nitrogen removal process) in Minnesota, USA was used as the inoculation sludge for the anaerobic / anoxic-aerobic sequencing batch reactor. The anaerobic / anoxic-aerobic sequencing batch reactor is a plexiglass column with an inner diameter of 19.5 cm, a height of 40 cm, and an effective volume of 8 L. The air is supplied by the air pump through 5 sintered sand core aeration heads evenly distributed at the bottom of the reactor, the air flow of each aeration head is controlled by 5 independent glass rotameters, and the aeration volume of each aeration head is 0.6L / min, the total aeration rate of the reactor is 3L / min, and the corresponding air volume per unit reactor effective volume per unit time, that is, the aeration intensity is 6.3L / (m 3 s). The stirring paddle is connected to the bottom of the stirring shaft of the mixer, and it is stirred for 0.5h before ...

Embodiment 2

[0024] The residual sludge from the secondary sedimentation tank of Hangzhou Sibao Sewage Treatment Plant (A / O biological denitrification process) was used as the inoculation sludge for the anaerobic / anoxic-aerobic sequencing batch reactor. The reactor is a plexiglass column with an inner diameter of 20 cm, a height of 40 cm, and an effective volume of 8 L. The air is supplied by the air pump through 5 sintered sand core aeration heads evenly distributed at the bottom of the reactor, the air flow of each aeration head is controlled by 5 independent glass rotameters, and the aeration volume of each aeration head is 0.5L / min, the total aeration rate of the reactor is 2.5L / min, the air volume per effective volume of the unit reactor per unit time, that is, the aeration intensity is 5.2L / (m 3 s). The stirring paddle is connected to the bottom of the stirring shaft of the mixer, and it is stirred during the air pump aeration process and the first 50% of the anaerobic / anoxic stage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com