Composite building board and manufacturing method thereof

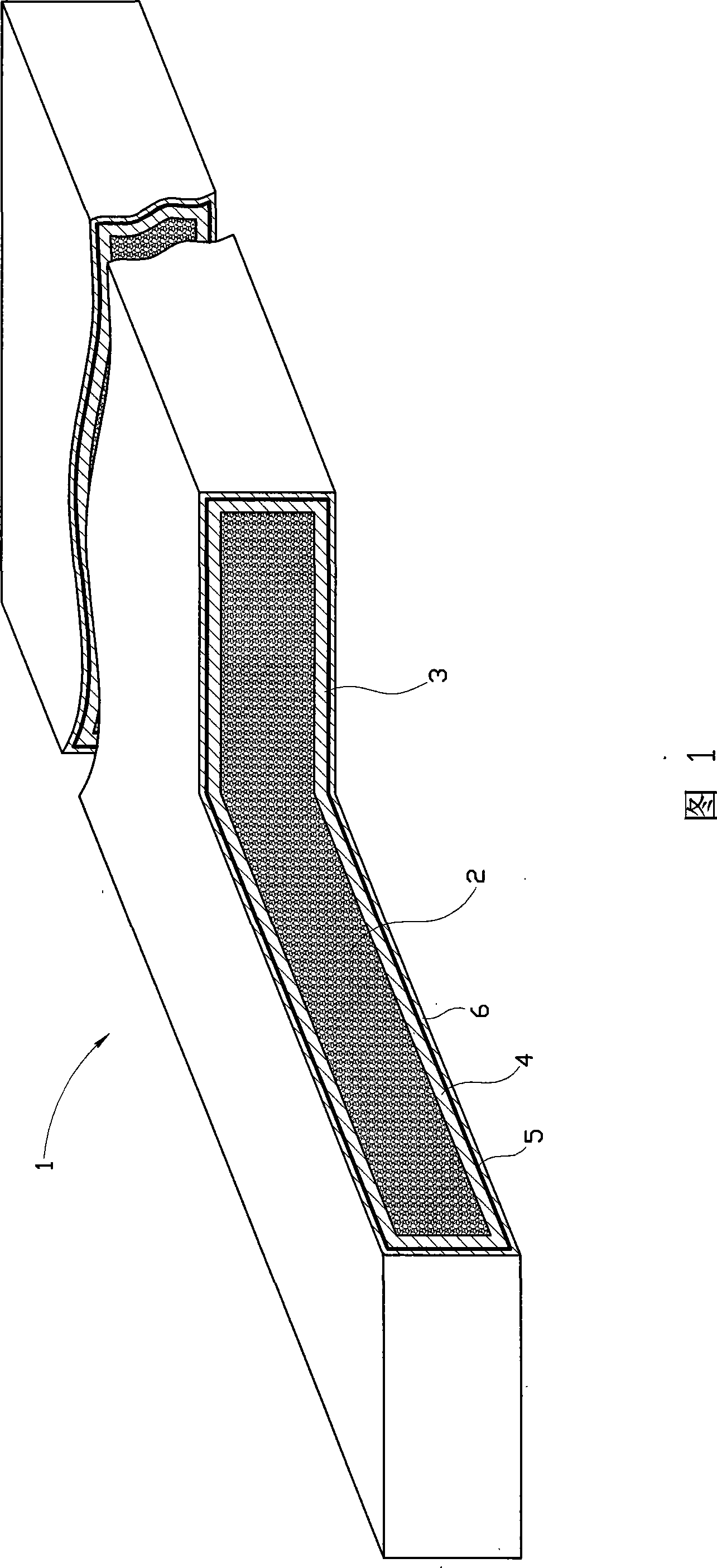

A technology for a building board and a manufacturing method, which is applied to building structures, buildings, building components, etc., can solve the problem that the cold protection and heat preservation performance of plastic greenhouses is not very good, the cold protection and heat preservation performance of livestock and poultry houses is not very good, and the overall strength of livestock and poultry houses is low. and other problems, to achieve the effect of light weight, good thermal insulation performance and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The manufacturing method of composite building board has the following steps:

[0030] (1) Lay plastic sheeting on a horizontal platform so that the plastic sheeting is flat without wrinkles;

[0031] (2) prepare magnesite concrete, the step of preparing magnesite concrete is:

[0032] ① Light-burned magnesia by weight: 100, brine: 65-80, glass short filament: 0.3-0.8, fly ash: 15-30, modifier: 1-1.5,

[0033] The above-mentioned light-burned magnesia is light-burned magnesia for magnesite products, and the brine is MgCl prepared with industrial magnesium chloride for magnesite products. 2 The weight concentration is 21%~25% MgCl 2 Aqueous solution, glass cloth is 4×4 medium-alkali or non-alkali glass cloth, glass short wire is medium-alkali or non-alkali glass short wire with a length of 10-30 mm and a diameter of 0.005-0.02 mm, and fly ash is pulverized coal discharged from thermal power plants Ash,

[0034] Above-mentioned modifying agent is composition, and the ...

Embodiment 2

[0048] In the step (2) in the above-mentioned embodiment 1, in the step (1) of preparing magnesite concrete, light-burned magnesia can be taken by weight: 100, brine: 70, modifier: 1.25, glass short filament: 0.5, fly ash : 20, other with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com