Low temperature drying technique of ebullience hatch type fishmeal

A drying process and low-temperature technology, applied in the field of low-temperature drying process of fish meal, can solve the problems of low cost performance, waste of steam, large heat energy consumption, etc., and achieve the effects of improving heating efficiency, not polluting the environment, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

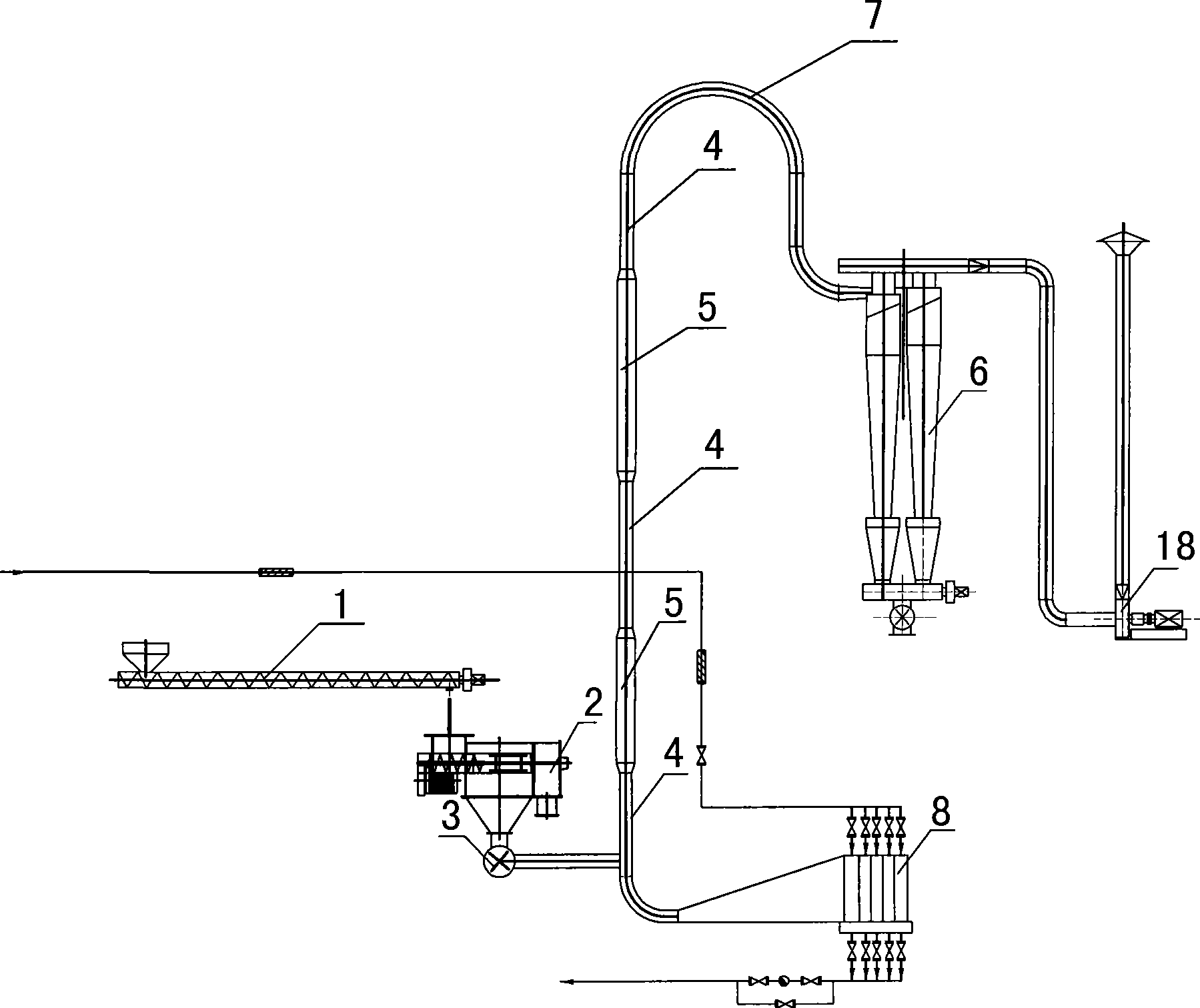

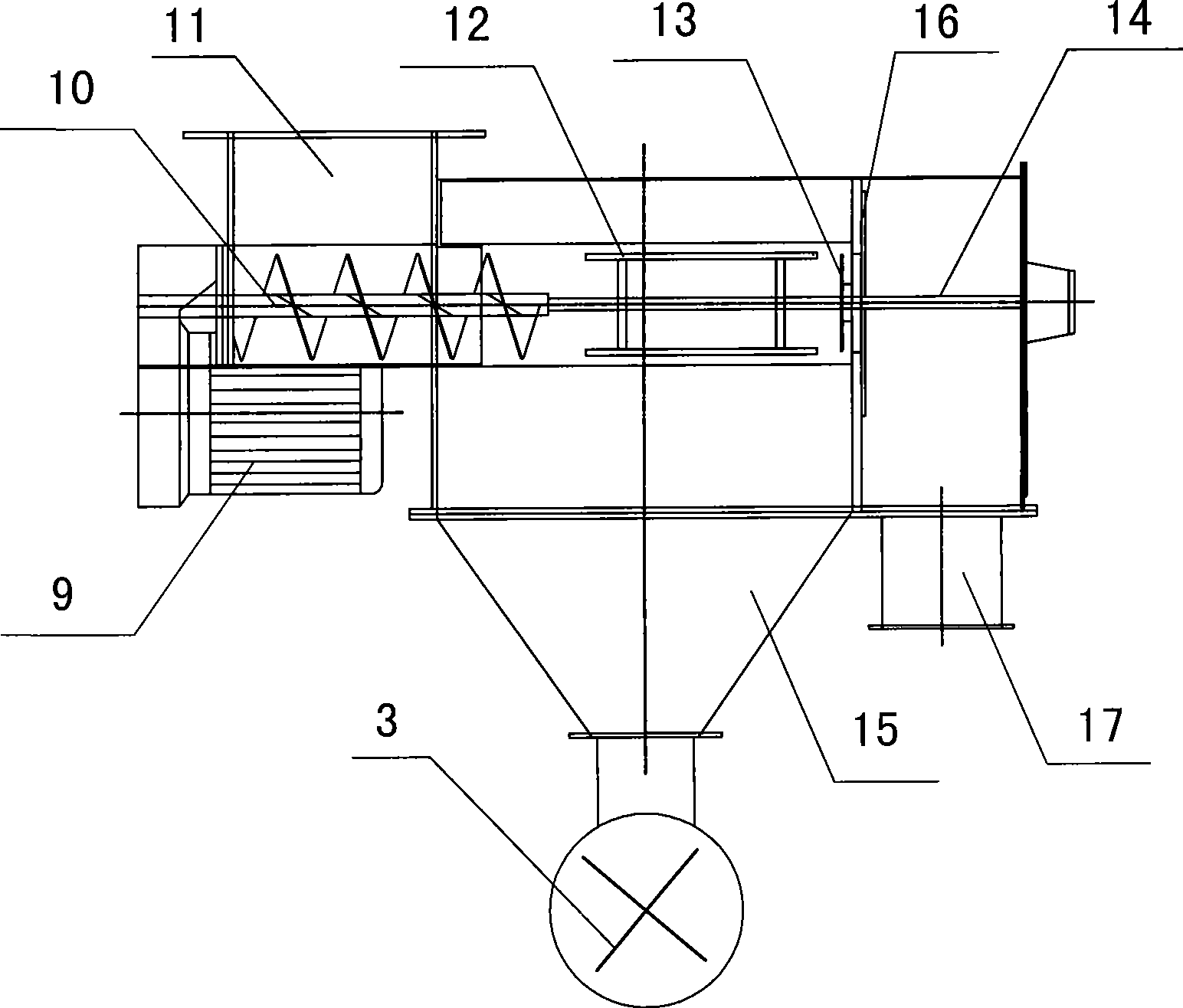

[0029] The water content of the wet fishmeal entering the boiling hatch type low-temperature dryer from the feeder 3 is 45%, the feed rate is 1500kg / h, the hot air wind speed through the heat exchanger 8 is 15-20m / s, and the temperature is 120°C. The inner diameter of the tube is 400mm, the inner diameter of the boiling tube is 500mm, and the total height is 22m. The heights of the rising material tube and the boiling tube from the bottom are respectively: the initial lifting tube 5m, the boiling tube 1.5m, the lifting tube 8m, and the boiling tube 1.5m m, lifting pipe 6m. The qualified fish meal discharged by the centrifugal unloader 6 has a water content of 10%, and the economic and technical indicators meet the requirements of the above-mentioned Table 1.

Embodiment 2

[0031] The water content of the wet fishmeal entering the boiling hatch type low-temperature dryer from the feeder 3 is 53%, the feed rate is 3000kg / h, the hot air wind speed through the heat exchanger 8 is 15-20m / s, and the temperature is 130°C. The inner diameter of the tube is 500mm, the inner diameter of the boiling tube is 630mm, and the total height is 25m. The heights of the rising material tube and the boiling tube from the bottom are set as follows: initial lifting tube 6m, boiling tube 2.5m, lifting tube 8m, boiling tube 2.5m m, lifting pipe 6m. The qualified fish meal discharged by the centrifugal unloader 6 has a water content of 10%, and the economic and technical indicators meet the requirements of the above-mentioned Table 1.

Embodiment 3

[0033] The water content of the wet fishmeal entering the boiling hatch type low-temperature dryer from the feeder 3 is 40%, the feed rate is 6000kg / h, the hot air velocity through the heat exchanger 8 is 15-20m / s, and the temperature is 130°C. The inner diameter of the pipe is 600mm, the inner diameter of the boiling pipe is 800mm, and the total height is 28m. m, lifting pipe 8m. The qualified fish meal discharged by the centrifugal unloader 6 has a water content of 10%, and the economic and technical indicators meet the requirements of the above-mentioned Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com