A refining device for mineral slurry

A technology for minerals and slurry, which is applied in the field of refining devices for mineral slurry, can solve the problems of poor controllability of crushing particle size, large loss of steel balls, large volume, etc., and achieves compact structure, high work efficiency, and large volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

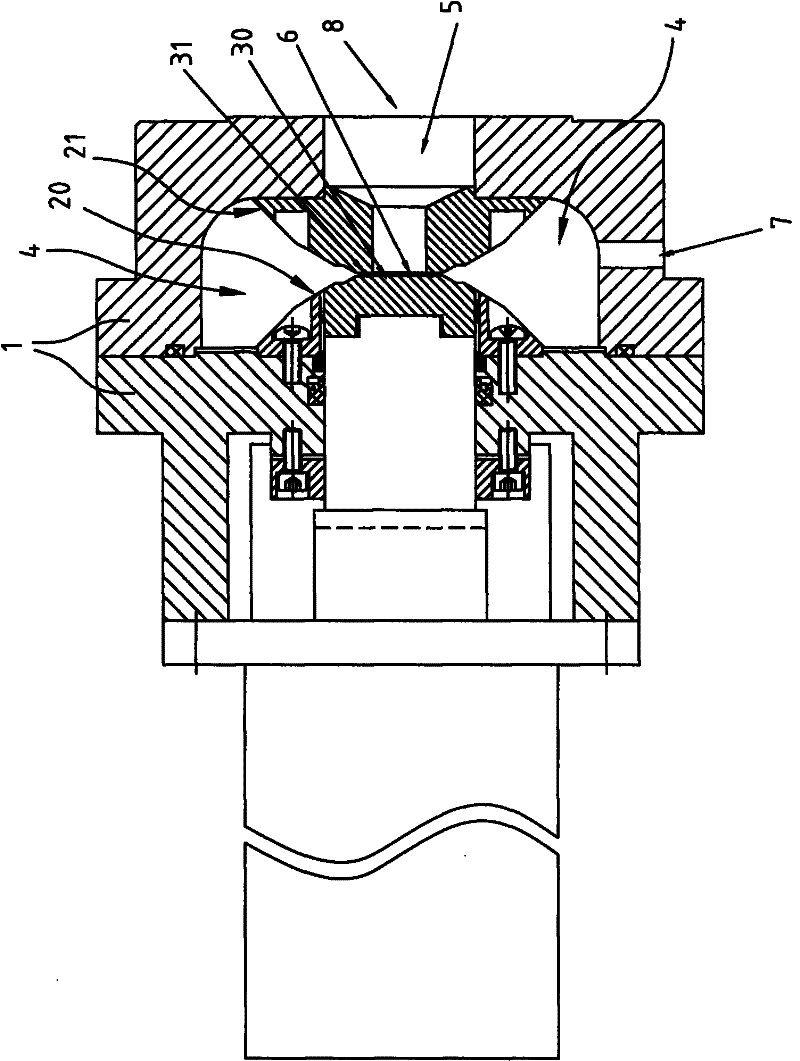

[0025] Embodiment 1: a kind of thinning device of mineral slurry, such as figure 1 As shown, it includes a housing 1 with a material inlet 7 and a material outlet 8. Two deflector plates 20, 21 are arranged in the housing 1. The edges of the guide discs 20, 21 are arc-shaped, and the There are valve bodies 30, 31 with high wear resistance on the top of the surface, and the outer surfaces of the valve bodies 30, 31 form frictional impact surfaces; the deflector plates 20, 21 and the surfaces of the valve bodies 30, 31 arranged oppositely form mineral slurry The jet cavity 4; a guide plate 21 and its valve body 31 have a through hole, the through hole forms a slurry channel 5; the area where the slurry channel 5 communicates with the jet cavity 4 forms an impact cavity 6.

[0026] The first valve body 30 on the first deflector plate 20 is connected to the driving mechanism, and the first valve body 31 on the second deflector plate 21 is fixed to the second deflector plate 21 . ...

Embodiment 2

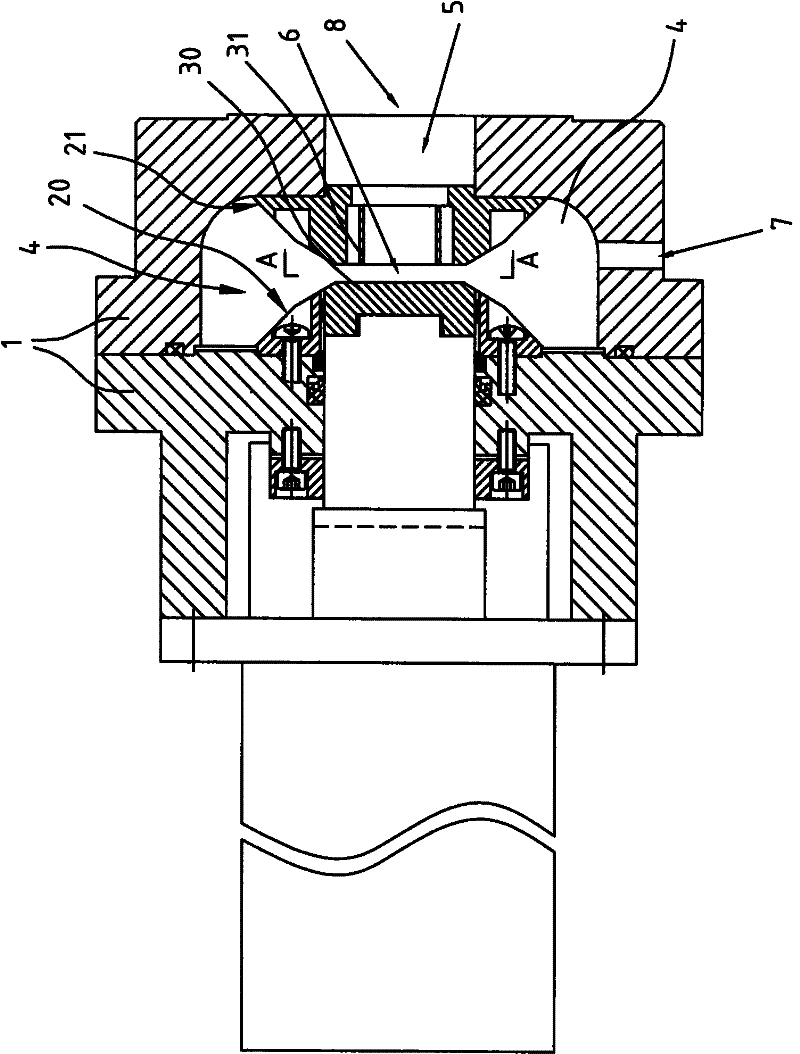

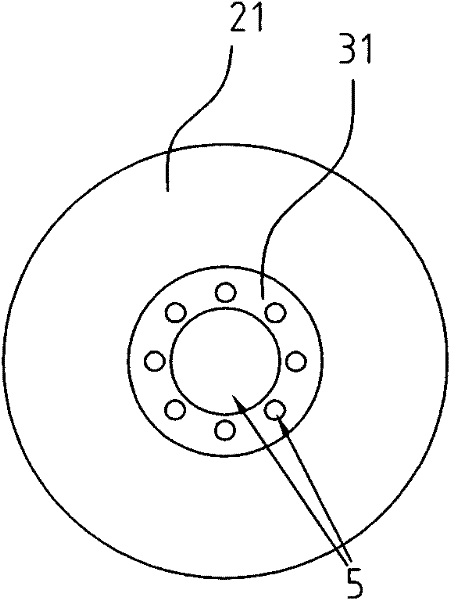

[0031] Embodiment 2: a kind of thinning device of mineral slurry, such as figure 2 and image 3 As shown, a guide plate 21 and its valve body 31 are provided with a plurality of through holes, and the plurality of through holes form a plurality of slurry channels 5 . All the other structures are the same as in Embodiment 1

Embodiment 3

[0032] Embodiment 3: a kind of thinning device of mineral slurry, such as figure 1 , figure 2 , Figure 4 , Figure 6 , Figure 8 and Figure 10 As shown, the valve body on the guide plate and the main body of the corresponding guide plate are separate structures. All the other structures are with embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com