Radial multi-cylinder synchronous revolving compressor

A technology of rotary compressors and cylinders, applied in multi-stage pumps, mechanical equipment, machines/engines, etc., can solve problems such as large vibration or resonance amplitude, unfavorable compressor cylinder heat dissipation, easy wear of piston rings, etc., to achieve pulsation Short time, low power consumption, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

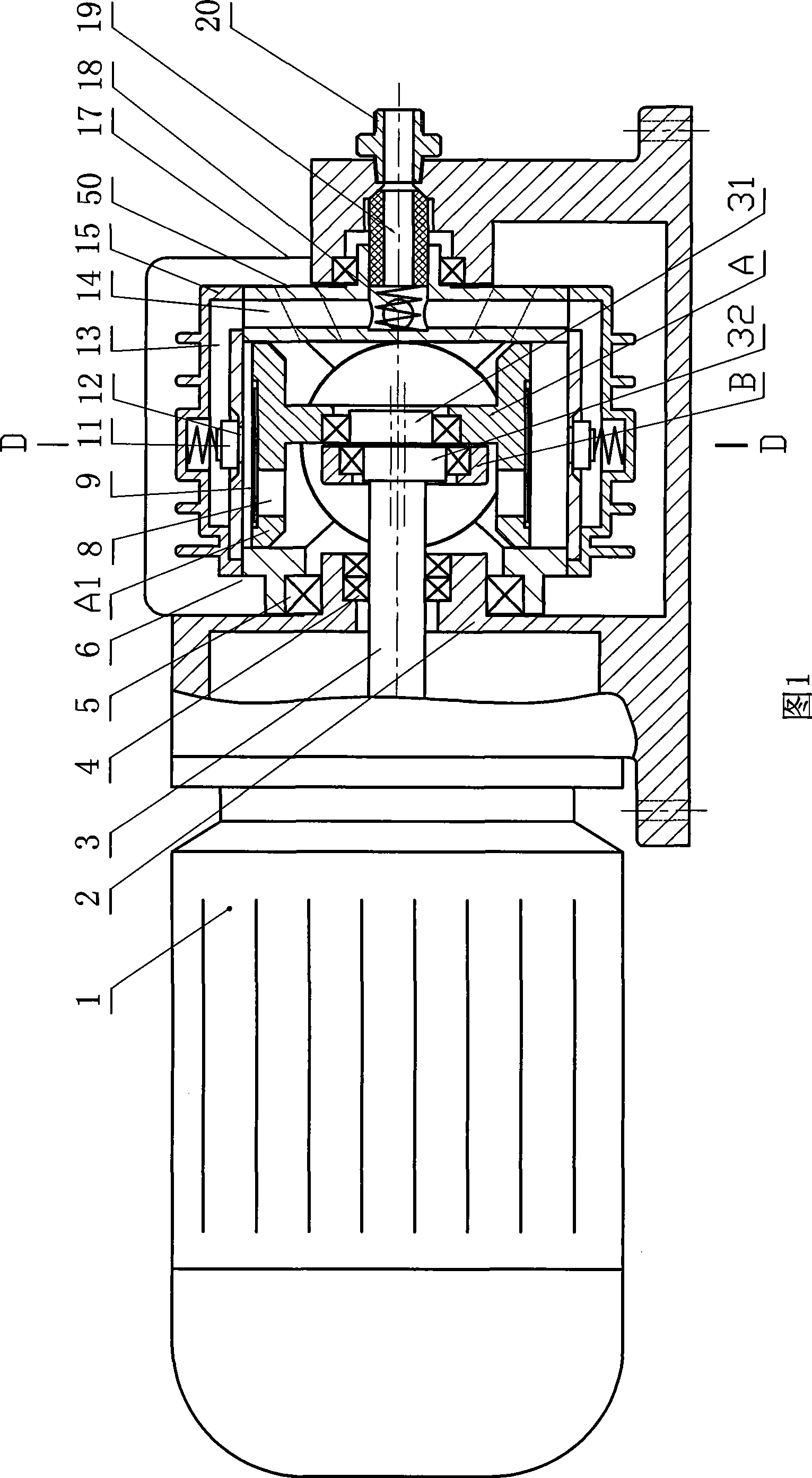

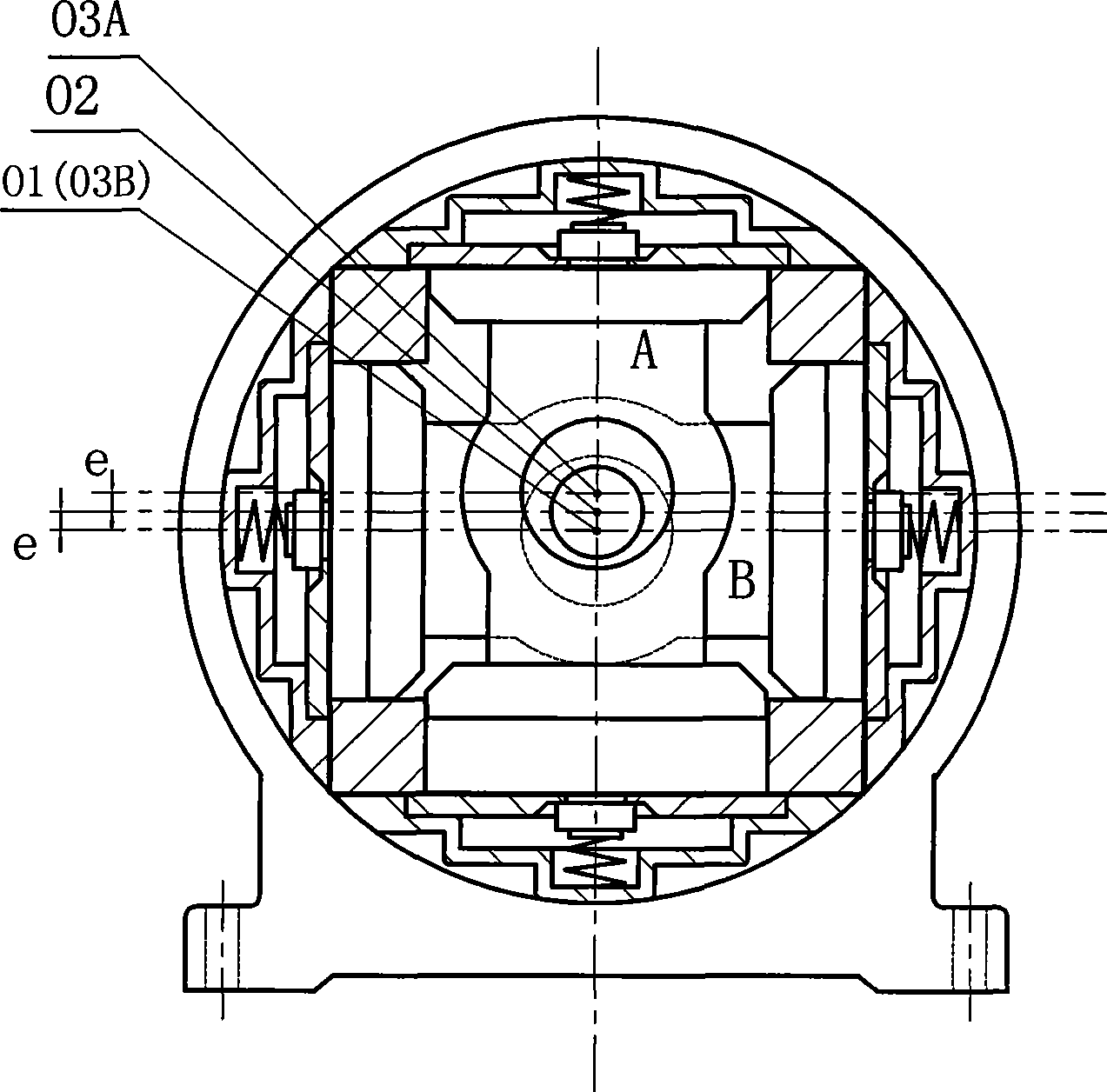

[0025] Embodiment 1: see Fig. 1-5:

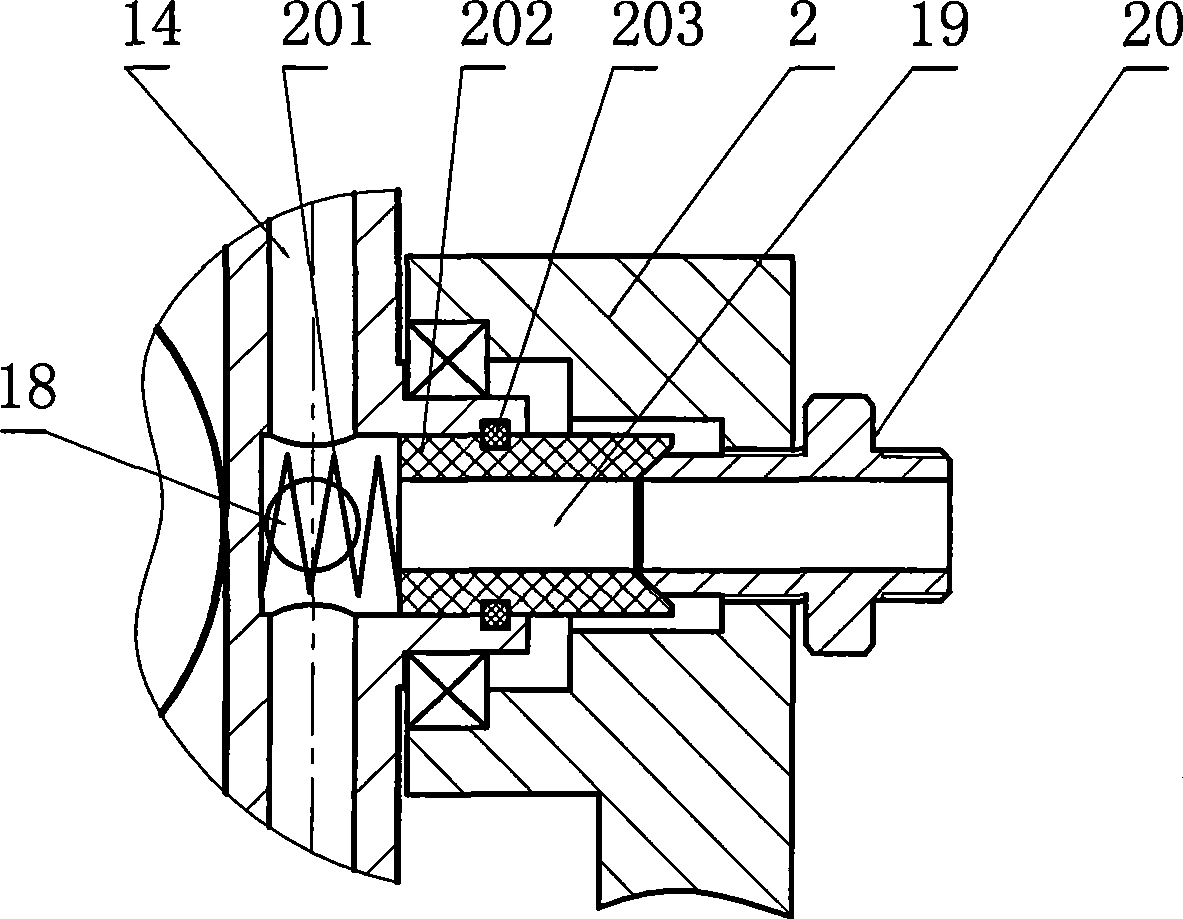

[0026] Radial multi-cylinder synchronous rotary compressor, including crankshaft 3 driven by motor 1, cylinders 50, 51 and cylinder head 15 forming cylinder body 6, bearing 4 supporting crankshaft 3, frame 2, reciprocating in cylinder body 6 The moving piston is characterized in that two symmetrically arranged eccentric journals 31, 32 are arranged on the crankshaft 3 driven by the motor 1, and cylinders 50 and 51 uniformly distributed along the circumference are arranged on the same plane perpendicular to the crankshaft 3, Two-way working pistons A and B are arranged in the cylinders 50 and 51. The crankshaft 3, the cylinder body 6, and the two-way pistons A and B can rotate synchronously around their respective centers of rotation O2 and O1. The exhaust port 12 and the exhaust valve 11 that the cylinder body 6 inner cavity communicates, the exhaust port 12 is introduced into the central hole 18,19 on the frame by the passage 13,14 that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com