Thermal technique device, method for cleaning translucent element thereof and technique for utilizing the device

A thermal process and component technology, applied in the field of semiconductor process and semiconductor devices, can solve problems such as affecting machine utilization time, increase maintenance cost, product scrap, etc., and achieve the effect of improving process yield, reducing process cost, and reducing replacement frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, examples will be given to further illustrate the present invention, but these examples are not intended to limit the scope of the present invention.

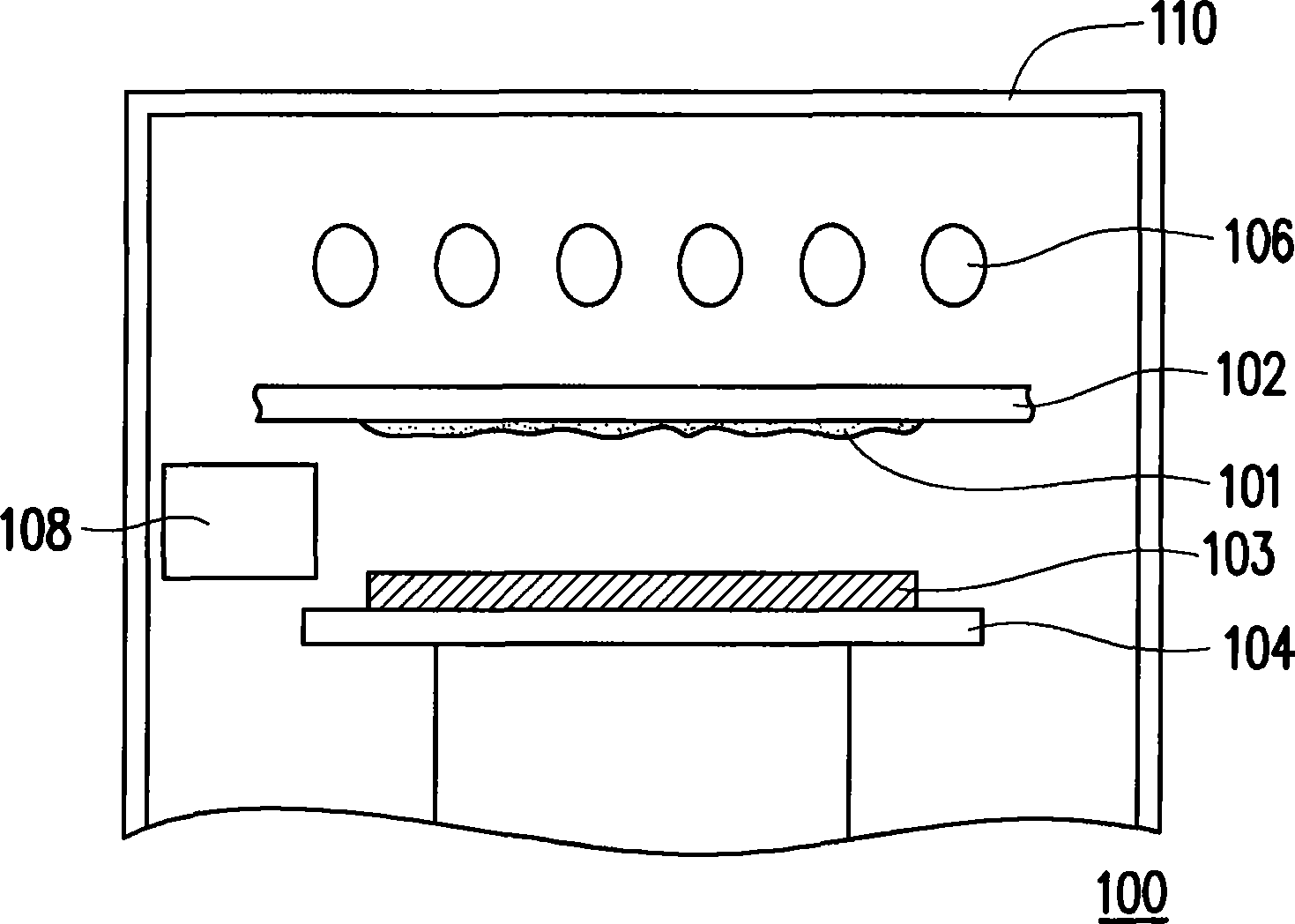

[0040] First, please refer to figure 1, which is a thermal process device according to an embodiment of the present invention. The thermal processing device 100 is suitable for thermal processing in general semiconductor processes, especially for rapid thermal processing (RTP). For example, it is suitable for metal silicide (salicide) process; deposition process for forming silicon oxide, silicon nitride and silicon oxynitride; treatment process for forming low dielectric material; and UV curing process. Of course, it can also be applied to rearrange the crystal lattice and eliminate stress concentration after performing multiple processes such as ion implantation and silicidation, or to form borophospho-silicate glass (Borophospho-silicate Glass, BPSG) and annealing processes such as nitriding.

[0041] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com