Coated glass pane

A glass plate, coating technology, applied in the direction of thin material handling, transportation and packaging, etc., can solve the problem of unsatisfactory resistance to mechanical and chemical influences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

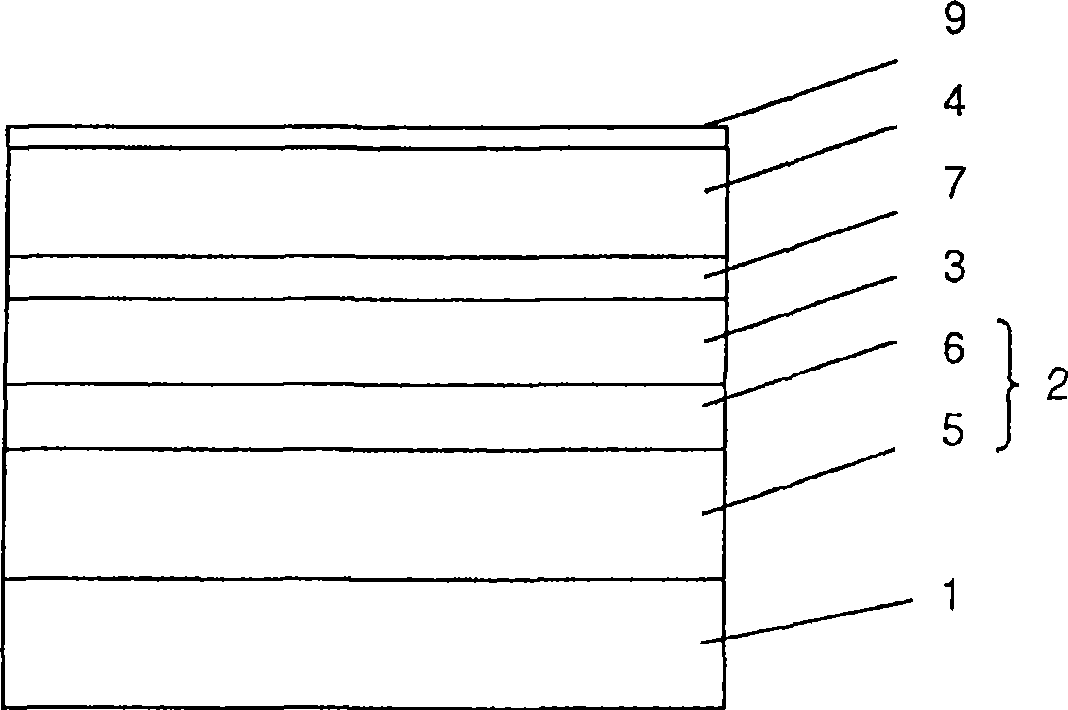

Embodiment 1

[0102] Coatings comprising the several layers indicated in Table 1 below were deposited onto glass plates in a sputtering apparatus with several separate sputtering chambers in which the following targets or pairs of targets were placed:

[0103] (1) The first target pair, including:

[0104] (a) metal-doped silicon target (in SISPA TM 10 commercially available from W.C. Heraeus), which contains about 10 wt.% of Al as the main dopant, and

[0105] (b) Ceramic aluminum-doped zinc oxide target (ZAO TM Commercially available from W.C. Heraeus), which contains about 2 wt.% Al 2 o 3 ;

[0106] (2) Zinc target;

[0107] (3) silver target;

[0108] (4) A second target pair, comprising

[0109] (a) Ceramic TiO x Target (xx CLATO TM Commercially available from W.C. Heraeus)

[0110] (b) Ceramic ZnO:Al target (ZAO TM Commercially available from W.C. Heraeus), which contains about 2 wt.% Al 2 o 3 .

[0111] The sputtering device allows moving the glass plate at a controlled...

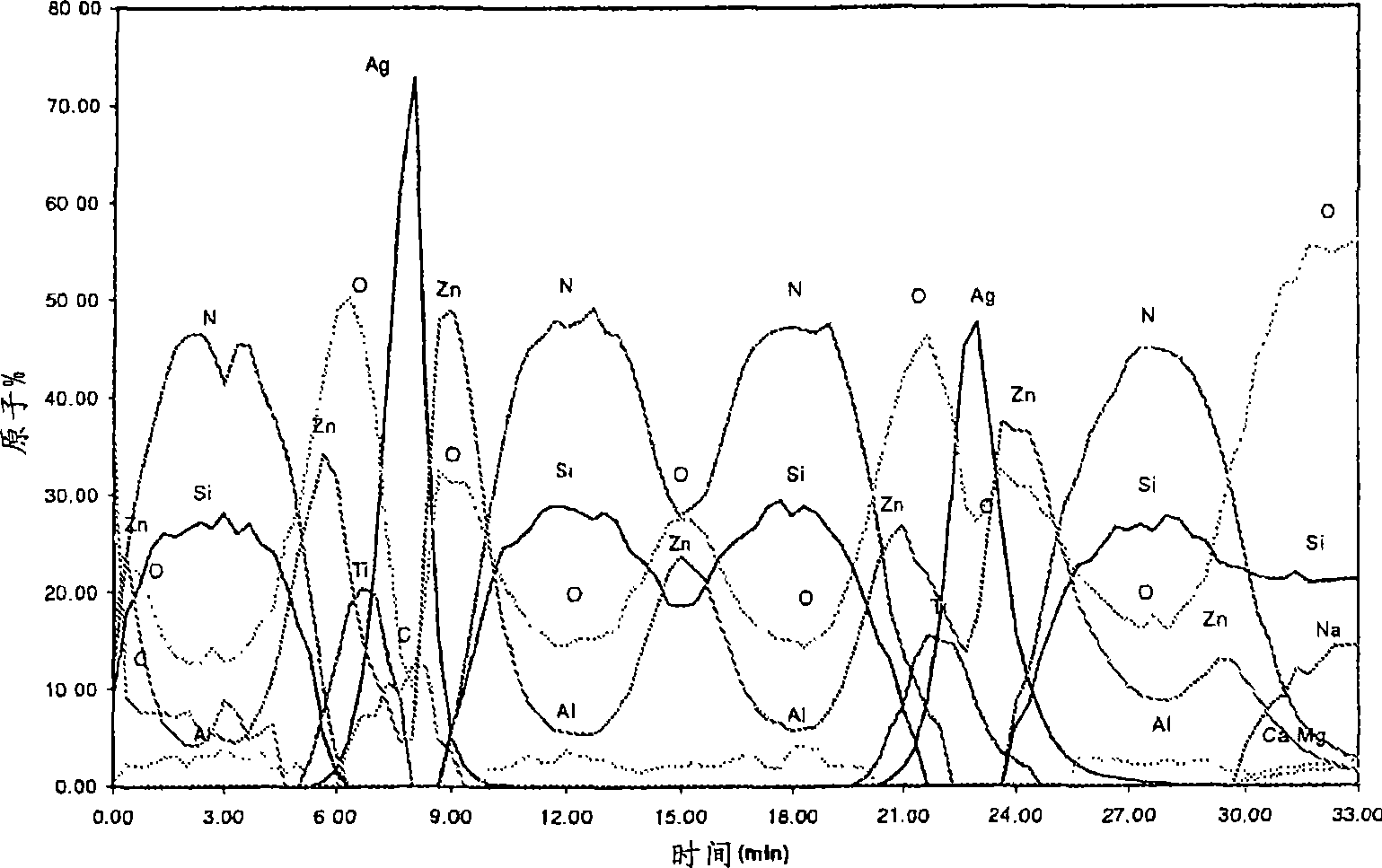

Embodiment 2

[0121] A coating with essentially the same layer sequence and thickness as in Example 1 was deposited. However, the difference from Example 1 is that the compound layer is deposited by moving the substrate about 4 times faster under the Al-doped Si(Si:Al) / Al-doped ZnO(ZnO:Al) target pair , and by correspondingly employing 8-16-8 moves to deposit 3 compound layers having substantially the same total thickness as in Example 1. Table 3 summarizes the deposition conditions:

[0122] table 3

[0123] Attached picture

mark

target composition

the power

[kW] the power

Types of Ar

[sccm] N 2

[sccm] o 2

[sccm] speed

[mm / min] move

frequency

15

Si:Al /

ZnO:Al

10 / 2

Pulse DC

200

150

-

3284

8

16 Zn 14 DC 140 - 450 5900 1 13 Ag 1.5 DC 250 - - 1875 1

17

TiO x /

ZnO:Al

3 / 3

Pulse DC

...

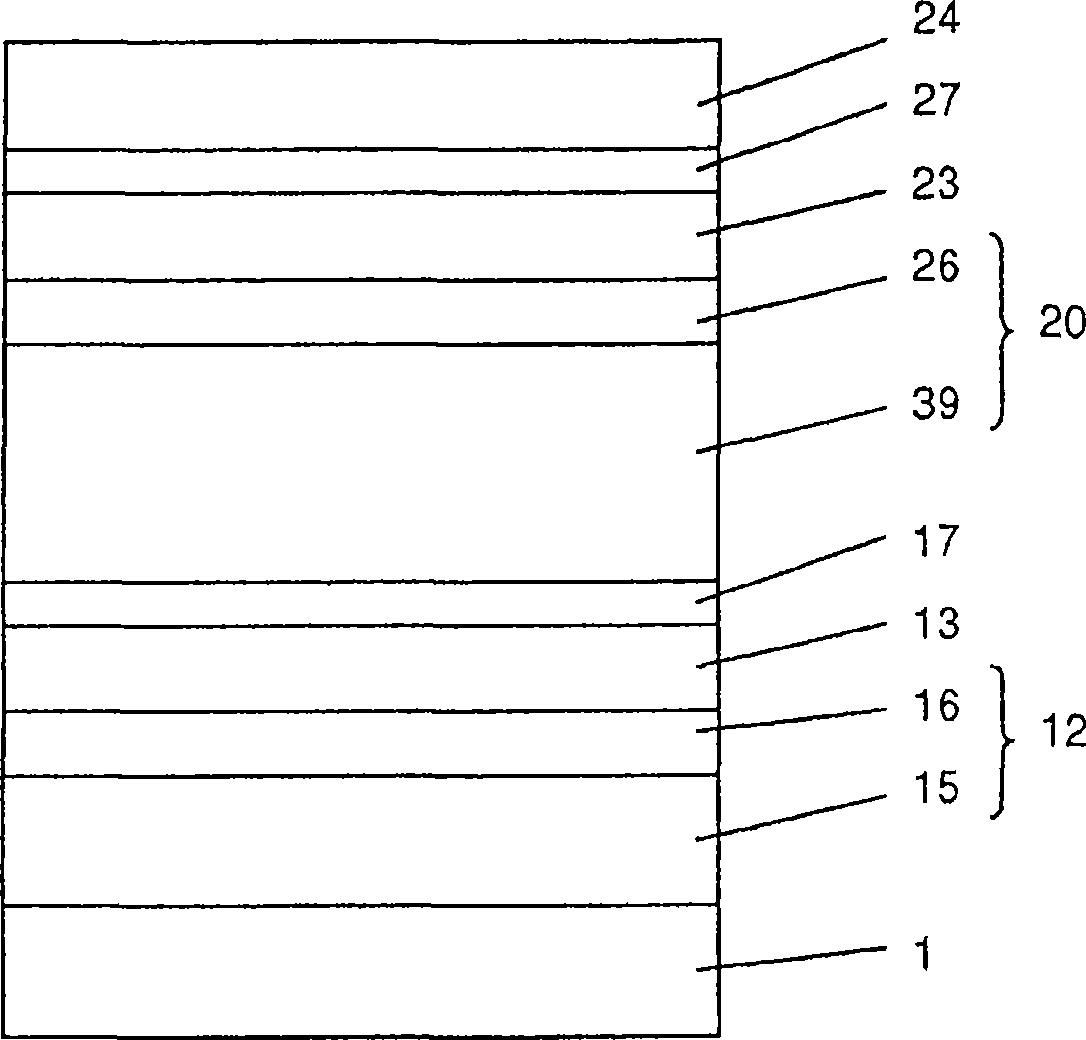

Embodiment 4-9 and comparative example 10

[0139] In another series of experiments, the Si:Zn atomic ratio in the compound layer of a coating with a layer sequence similar to that of Example 1 was varied, with the following differences in addition:

[0140] - set the thicknesses of the compound layers 15, 39 and 24 in the coating of the invention and the (aluminum-doped) silicon nitride layer in the comparative coating of Comparative Example 10 to 40, 80 and 40 nm, respectively (as in Example 1 and 35, 70 and 35 nm in Comparative Example 3), a 2-4-2 movement was achieved under the target at a slightly reduced rate.

[0141] - The power ratio of the Si:Al / ZnO:Al target used to deposit the compound layers 15, 39 and 24 of a further embodiment of the invention was varied between 15:2 (Example 4) and 15:8 (Example 9) , thus achieving in these layers the Si:Zn atomic ratio shown in the second column of Table 5 below (from XPS analysis) (compared to about 2:1 in Examples 1 and 2).

[0142] All coated glass panels were heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com