High intensity alloyed steel traction pin and welding process of foundation

A welding process and traction pin technology, which is applied in the field of base welding process between high-strength alloy steel traction pins and ordinary low-carbon steel, can solve the problems of low production efficiency, unsatisfactory impact toughness of welds, etc., and prolong the service life. , The effect of solving insufficient welding seam fusion and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

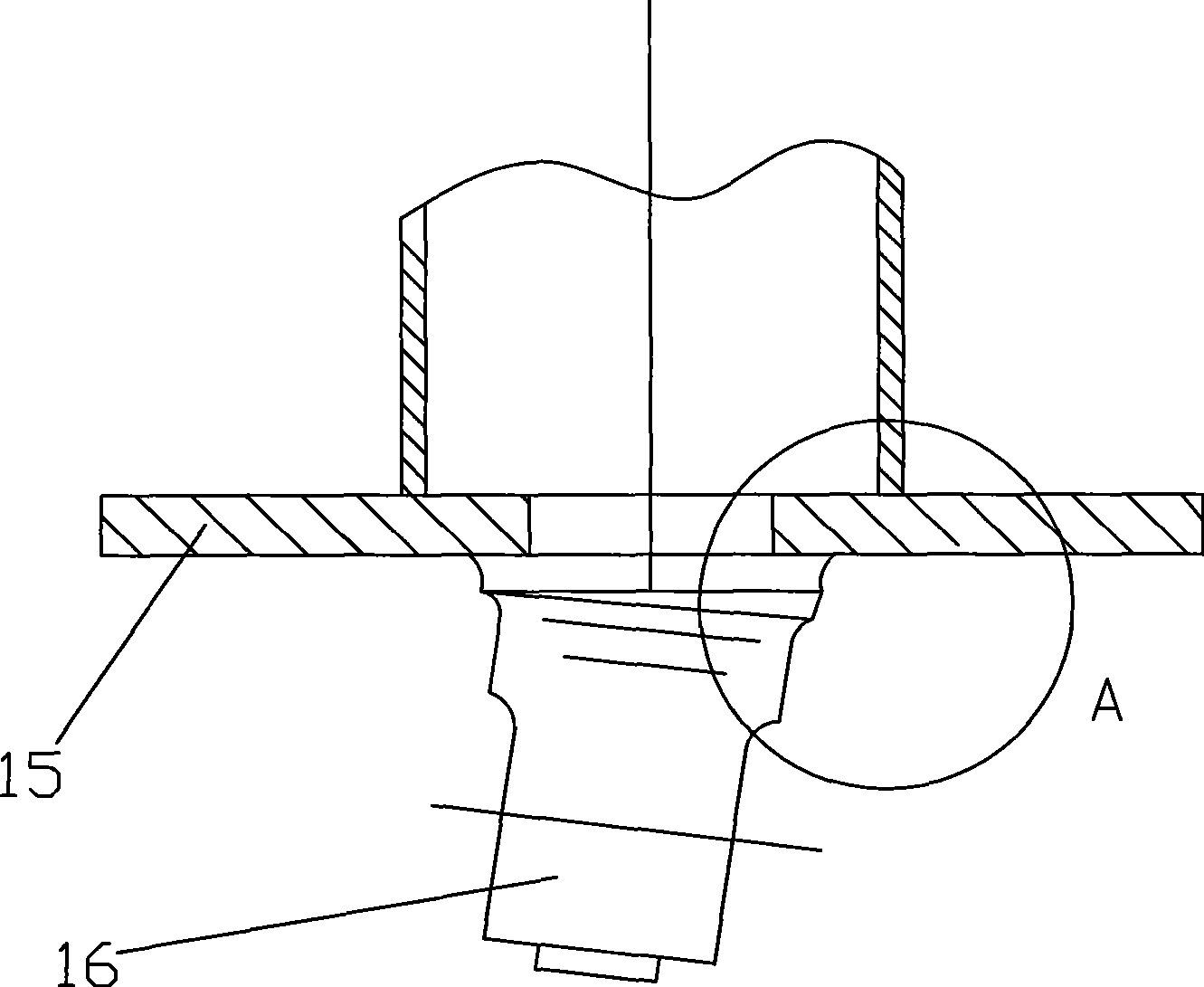

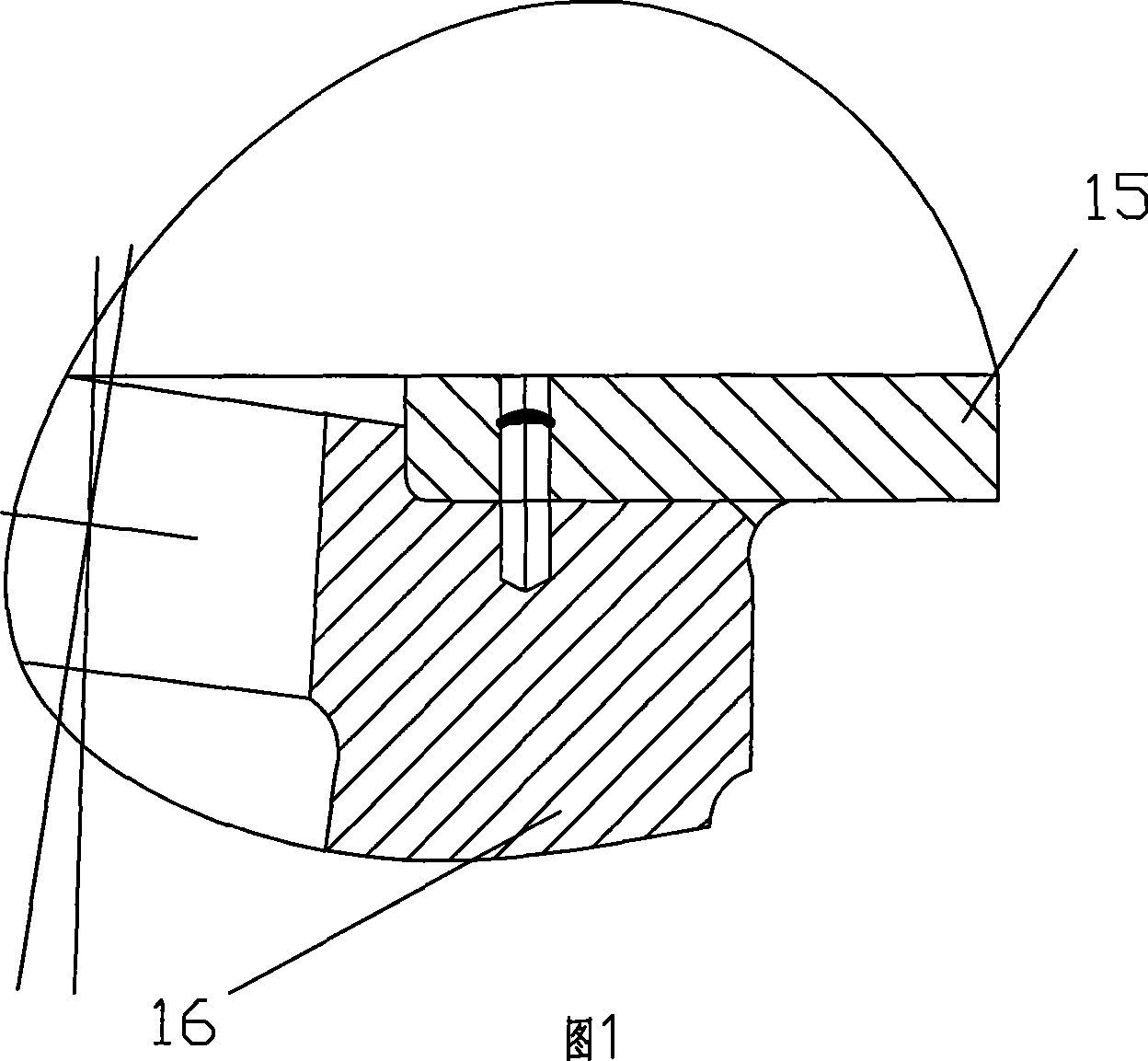

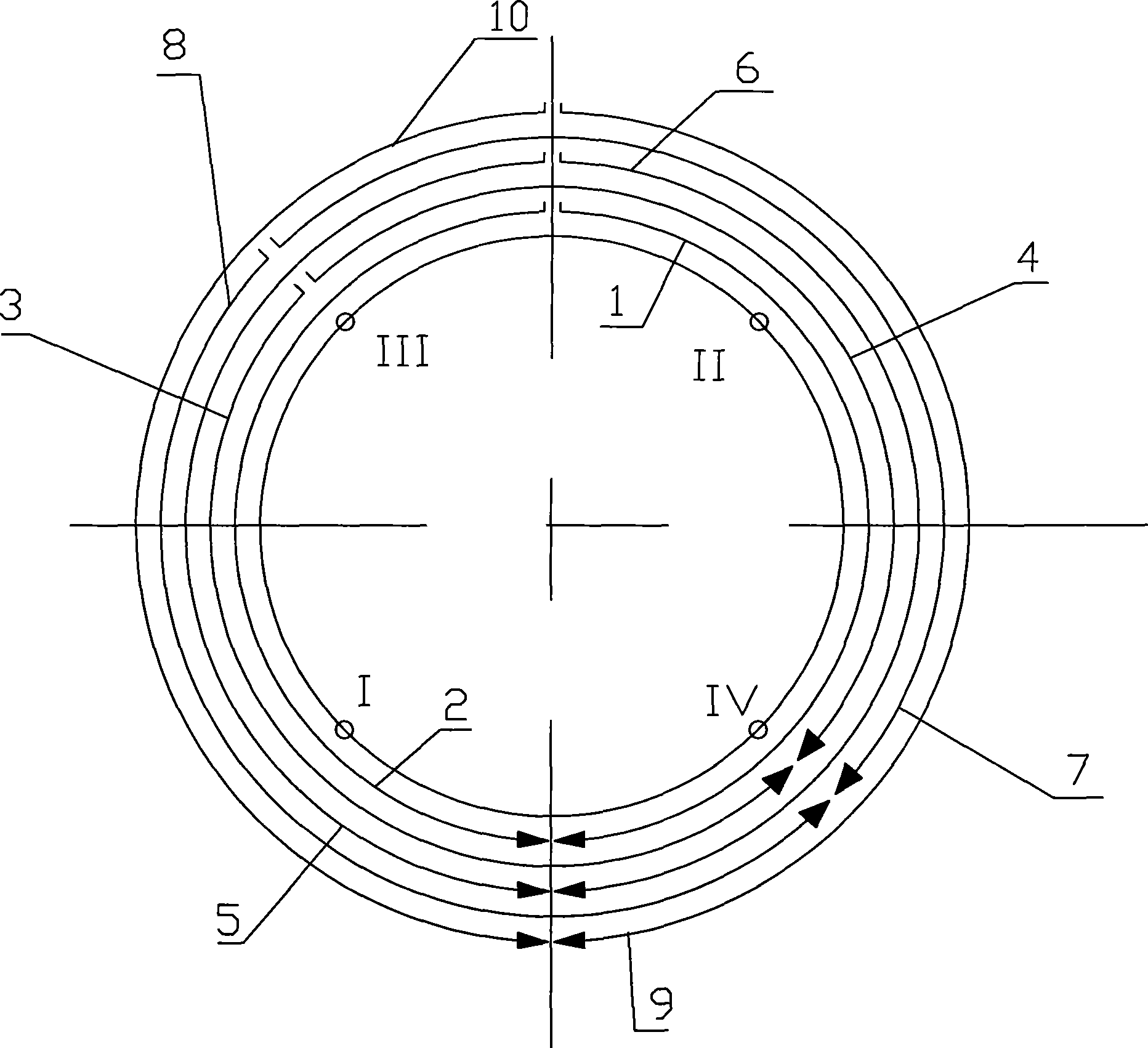

[0025] Such as figure 1 , shown in 2: 15 is a base, and 16 is a traction pin. Since the material of the traction pin contains elements such as Cr, Ni, Mo, etc., when selecting the filler metal, the chemical composition should be as close as possible to that of the base metal. In addition, the tensile strength of the tractor pin after heat treatment should reach 750-900MPa, and the tensile strength of the base connected to it should be 470-690MPa, so the strength of the filler metal should be as suitable as possible for the two different base materials, while ensuring that the weld seam impact toughness requirements. Therefore, the welding process proceeds as follows:

[0026] a. Determine the welding filler material according to the material of the traction pin and the base. The welding filler material is selected from alloy steel flux-cored welding wire AWS81T1-Ni, the diameter of the welding wire is Φ1.2mm, and the tensile strength is between 550MPa-690MPa;

[0027] b. Be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com