Glass substrate laser cutting apparatus

A glass substrate and cutting technology, which is applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve the problems of uneven cutting surface and increase the cost of consumables, so as to reduce the operation cycle, increase the workload, and prevent cutting Cutting precision and safety reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

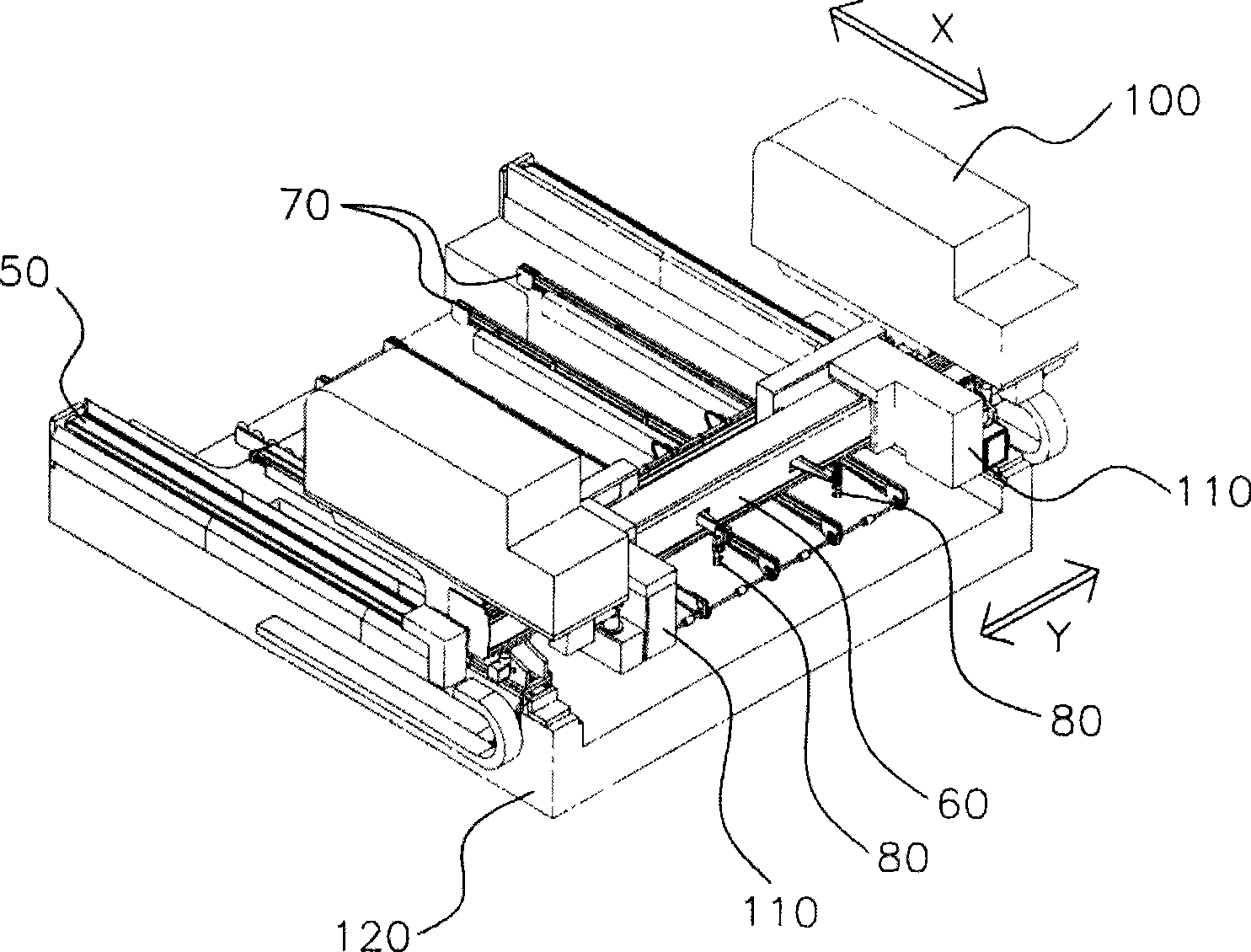

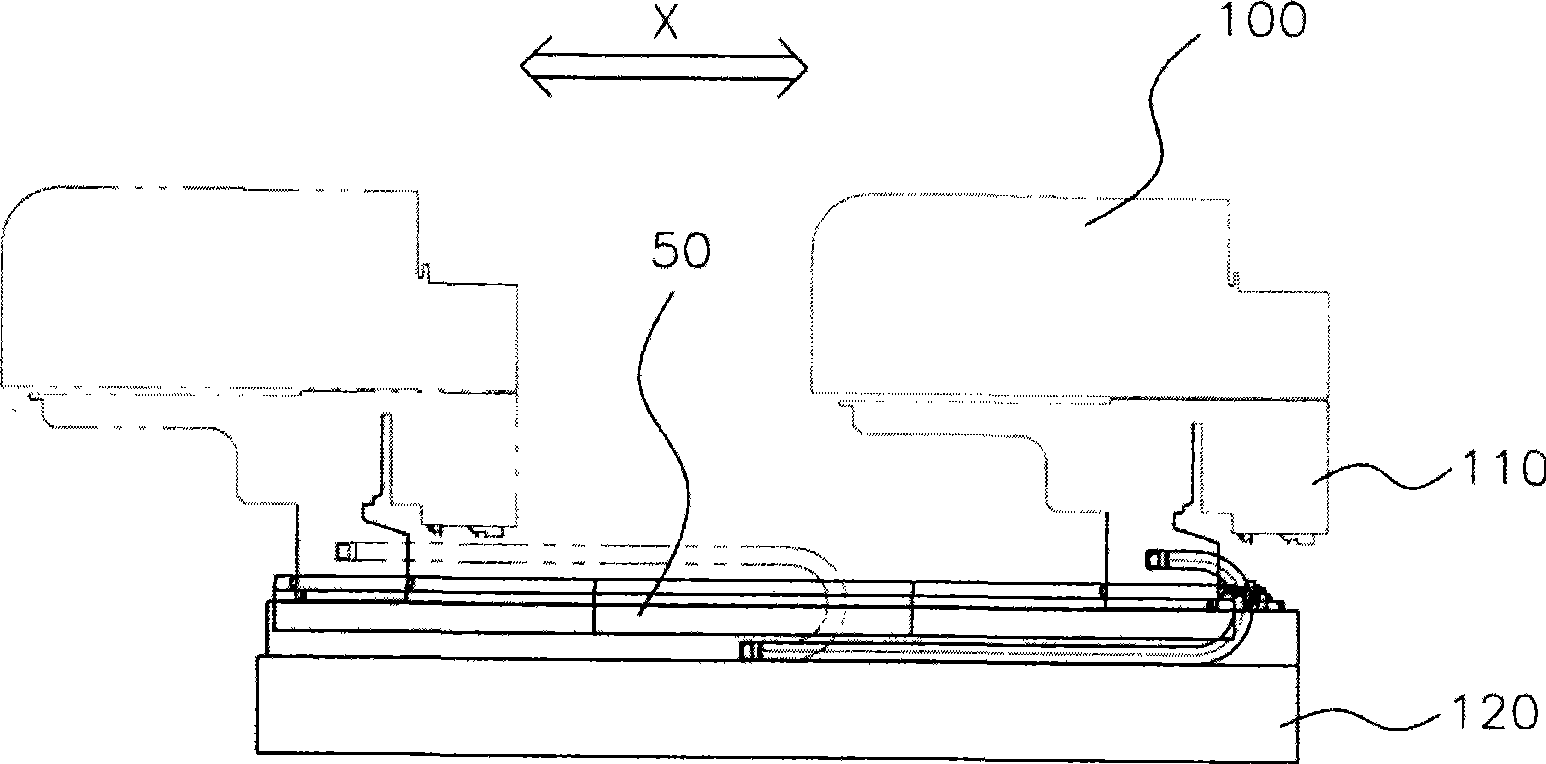

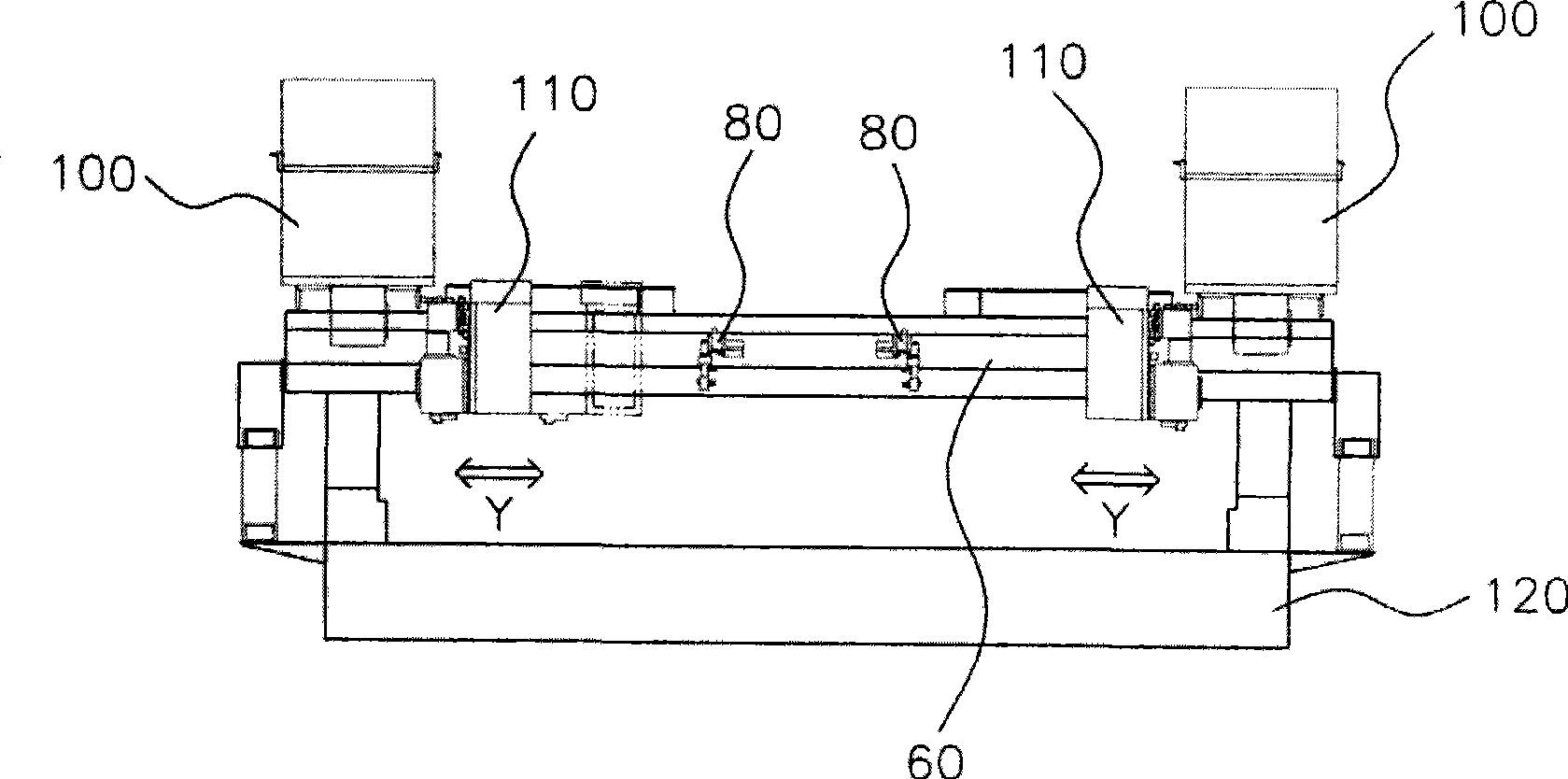

[0040] figure 1 It is a three-dimensional view of the overall structure of the glass substrate laser cutting device of the present invention, Figure 2a and 2b They are the side view of the glass substrate laser cutting device showing the stage structure moving along the stage platform, and the front view of the glass substrate laser cutting device showing the laser irradiation head moving along the stage structure.

[0041] refer to figure 1 and Figure 2a , 2b , the glass substrate laser cutting device of the present invention has:

[0042] The cutting table 120 keeps the glass substrate to be cut in a horizontal state;

[0043] A pair of stand platforms 50 are assembled in parallel at both ends of the cutting table 120 in order to move the stand structure 60;

[0044] The platform structure 60 is vertically arranged on the top of the platform 50 and perpendicular to the platform 50, and can move along the platform 50;

[0045] The laser emitting part 100 is fixedly arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com