Alkene hydroformylation flow reactor

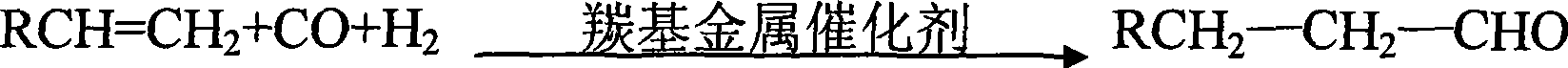

An olefin hydroformyl and reactor technology, which is applied to the preparation of carbon monoxide reaction, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of high maintenance costs, short service life and increased investment costs and other problems, to achieve the effect of reducing operating costs, production costs and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

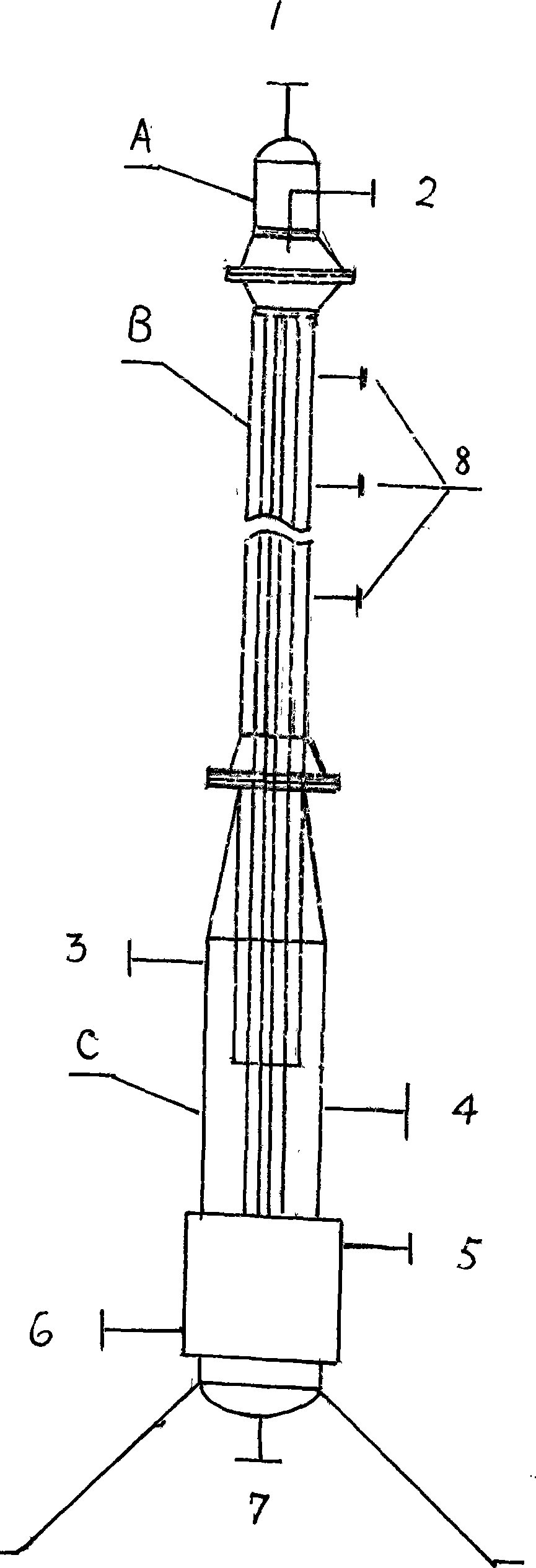

[0030]A continuous reactor for olefin hydroformylation, which consists of three parts: the upper gas-liquid distribution section A, the middle mass transfer reaction section B and the lower gas-liquid separation section C (see Figure 1), the upper gas-liquid The distribution section A has a mixed gas inlet pipe composed of hydrogen and carbon monoxide, a gas distributor 1, and a catalyst solution inlet pipe and a liquid distributor 2. The mass transfer reaction section B in the middle is cylindrical, with a diameter of 59 mm and a height of 2500 mm ( Excluding the part extending into the gas-liquid separation section C), the inside is filled with a hydrophilic fiber membrane (Cr Ni Ti alloy, provided by Nanjing Jinlian Technology Development Co., Ltd.) with a diameter of 0.01 to 0.2mm. There is a temperature sensor in section B, the mass transfer reaction section B is sealed with the gas-liquid distribution section A, the diameter of the gas-liquid separation section C is 159mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com