Method for producing square cross-section polyamide fibre and use thereof

A technology of polyamide fiber with square section, applied in fiber processing, textiles, papermaking, fabrics, etc., which can solve the problems of increased manufacturing cost, reduced cloth tear strength, and inability to fully meet the needs of airbags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

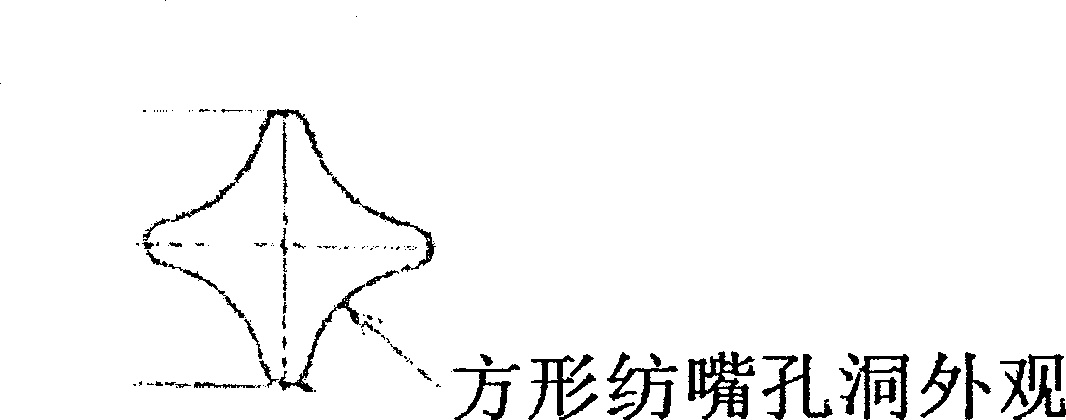

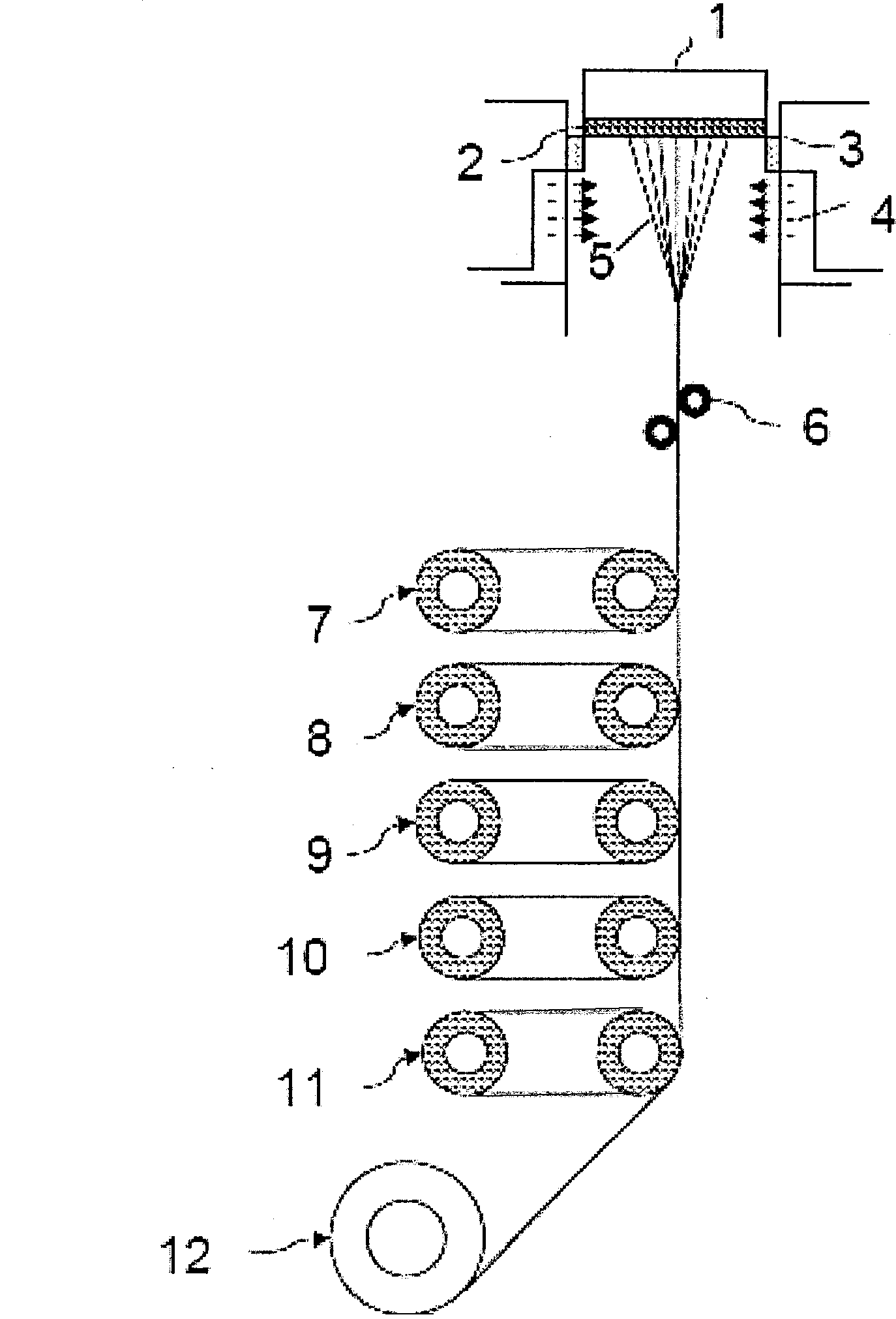

[0078] Such as image 3 As shown in the method flow, the polyamide 66 pellets with a relative viscosity (RV)=3.3 are melt-spun through the spinning assembly 1 at 292° C., and the molten polyamide 66 is passed through such as figure 2 The shown square spinning nozzle 2 is extruded, and after the filaments pass through the slow cooling zone 3 with a length (L) of 5 cm below the square spinning nozzle, cold air is supplied to the cooling zone 4 at a speed of 0.5 m / s The filaments are cooled and solidified, and after oiling the solidified spun yarn 5 passing through the cooling zone 4 through the oiling device 6, the total elongation ratio is 4.9 by 5 sets of continuous stretching rollers 7, 8, 9, 10 and 11. After double stretching and 7% relaxation treatment, the filaments are entangled by a blowing interlacer device (not marked), and the solidified spun filaments are coiled by a coiler at a speed of 2965m / min, and finally produced The polyamide fiber extended filament yarn 12 ...

Embodiment 2

[0081] According to the same method process and conditions as in Example 1, except that the length (L) used in Example 2 is a slow cooling zone of 10 cm, finally a polyamide fiber drawn filament yarn with a square cross-sectional shape is obtained.

[0082] Various physical property tests were carried out on the drawn drawn filament yarn, and the results are shown in Table 1.

Embodiment 3

[0084] According to the same method process and conditions as in Example 1, except that the slow cooling zone with a length (L) of 15 cm was used in Example 3, finally a polyamide fiber drawn filament yarn with a square cross-sectional shape was obtained.

[0085] Various physical property tests were carried out on the drawn drawn filament yarn, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com