Multiple-domain vertical orientating type liquid crystal display device and its manufacture method

A liquid crystal display device and vertical alignment technology, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of rising manufacturing costs, reducing pixel aperture ratio, and reducing the light-transmitting part of the pixel area, so as not to affect The effect of aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

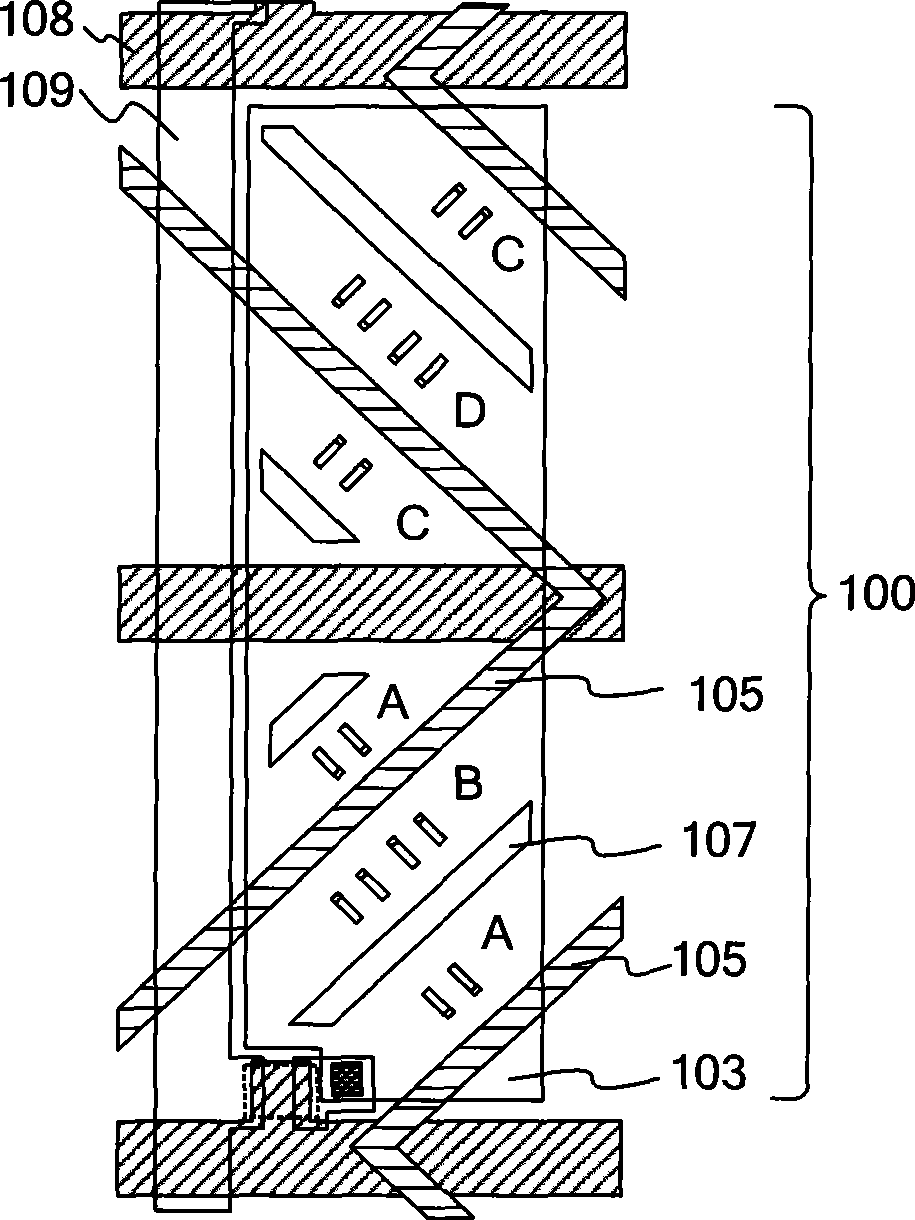

[0048] Figure 4A is a top view of the array substrate of the present invention, Figure 4B for along Figure 4A A cross-sectional view in the direction of A-A'.

[0049] See Figure 4A , the liquid crystal display device of the present invention includes: a first substrate (also known as an array substrate, not shown in the figure) and a second substrate (also known as a color filter substrate, not shown in the figure); Liquid crystal layer (not shown); scanning electrode lines 401 and signal electrode lines 406 intersecting each other on the first substrate and defining sub-pixel areas; controlled by scanning electrode lines 401 to open a thin film transistor switch 407, and signal electrode lines 406 pass through The switch charges the first pixel electrode 402; a second pixel electrode 405 is formed on the first substrate at the same time, and this electrode is not directly connected to the first pixel electrode 402 electrically, and is not connected to the thin film tr...

Embodiment 2

[0052] Figure 5 is a cross-sectional view of the array substrate in the second embodiment of the present invention.

[0053] See Figure 5 After the gate electrode, the gate insulating layer 408, the semiconductor layer, the drain / source electrode, and the passivation layer 410 are sequentially formed on the transparent substrate 408 in this embodiment, a layer of transparent electrode is made first, and a pattern is engraved as the first Pixel electrode 402; then apply insulating film 411, etch the insulating film 411 above the first pixel electrode 402 in the non-coupling region to expose the first pixel electrode 402; make a layer of transparent electrode, and carve a pattern as the second Pixel electrode 405 . The advantage of this method is that there is one less insulating film above the first pixel electrode 402, which improves the light transmittance.

Embodiment 3

[0055] Image 6 It is the production flowchart of the third embodiment of the present invention.

[0056] See Image 6 , this embodiment is a further improvement on the second embodiment. After the gate, gate insulating layer 408, semiconductor layer, drain / source, and passivation layer 410 are sequentially formed on the transparent substrate 408, a layer of transparent electrode is made first, and a pattern is carved as the first pixel electrode 402; then Coating the insulating film 411, and then making the second transparent electrode layer, etching out the pattern as the second pixel electrode 405 through the dry etching process; and then etching the insulating film 411 not covered by the second pixel electrode 405 through the wet etching process , exposing the first pixel electrode 402 . The advantage of this method is that it can save a photolithography process and reduce the cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com