Electrophoretic display device, method for driving electrophoretic display device, and electronic apparatus

An electrophoretic display and electrophoresis technology, applied in static indicators, nonlinear optics, instruments, etc., can solve the problems of increased power consumption, high-precision correspondence difficulties, and panel current consumption cannot be ignored, etc., to achieve power saving, The effect of suppressing manufacturing variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

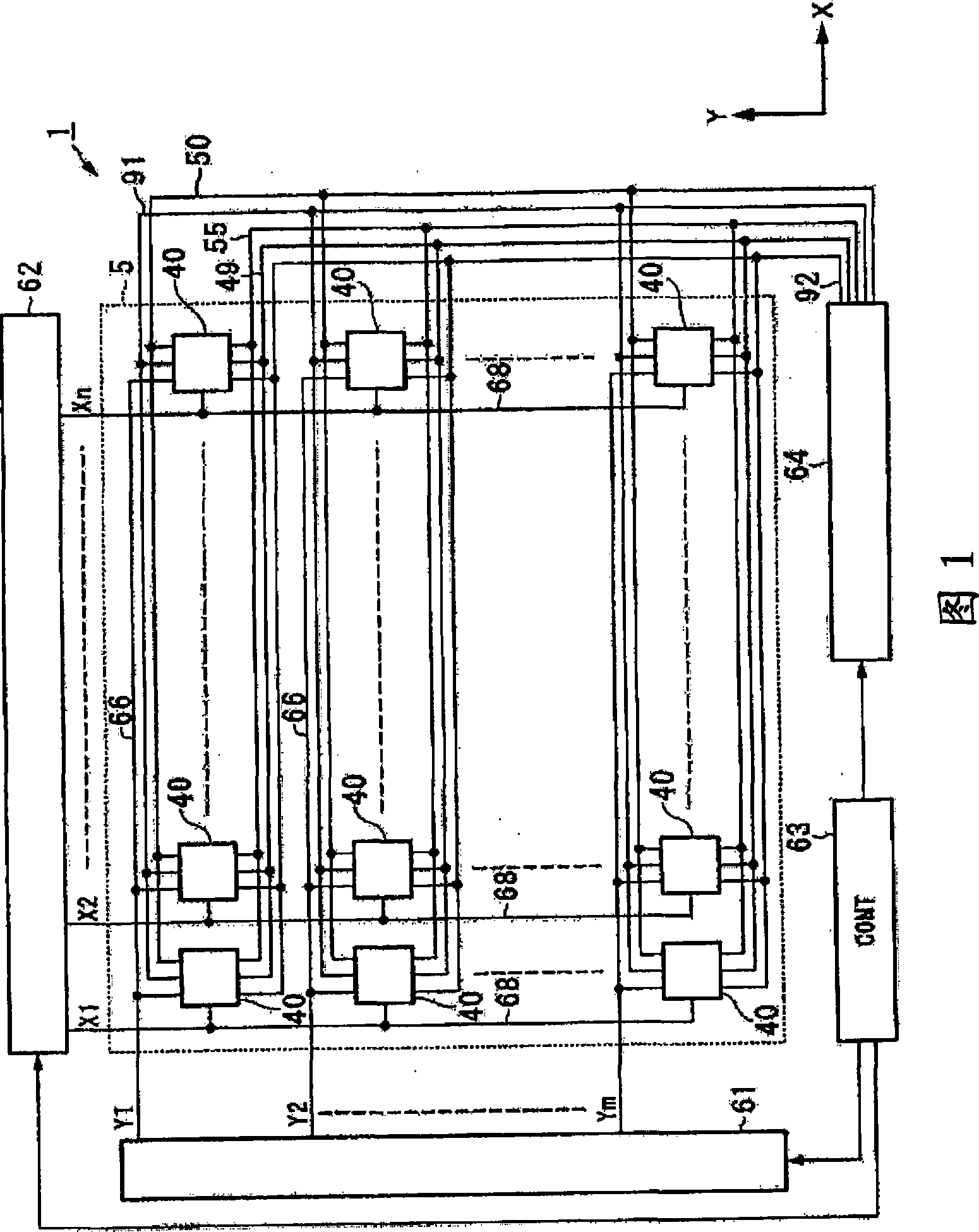

[0064] FIG. 1 is a schematic configuration diagram of an electrophoretic display device 1 of an active matrix driving method.

[0065] The electrophoretic display device 1 includes a display unit 5 in which a plurality of pixels 40 are arranged. Around the display unit 5, a scanning line driving circuit 61, a data line driving circuit 62, a controller (control unit) 63, and a common power modulation circuit 64 are arranged. The scanning line driving circuit 61 , the data line driving circuit 62 , and the common power modulation circuit 64 are respectively connected to the controller 63 . The controller 63 comprehensively controls them based on image data, synchronization signals, and the like supplied from a higher-level device.

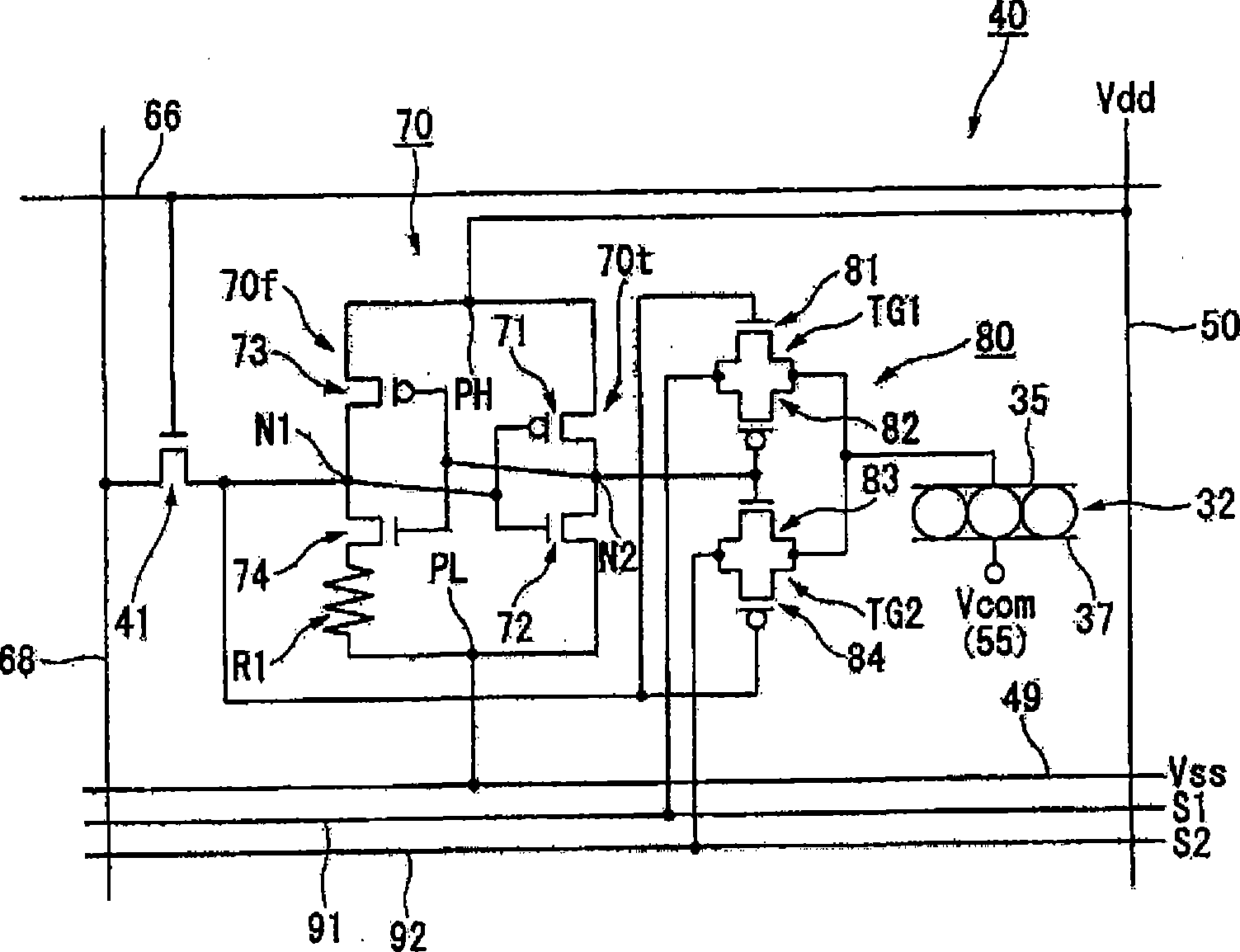

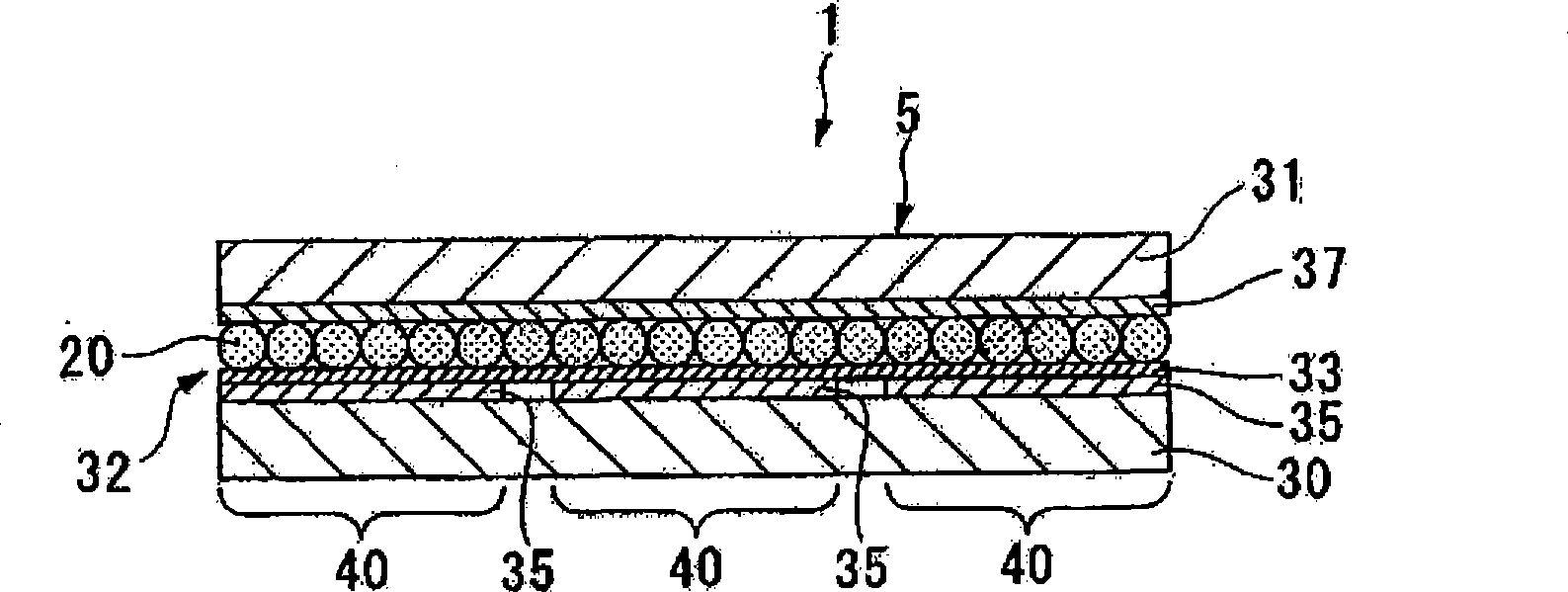

[0066] A plurality of scanning lines 66 extending from the scanning line driving circuit 61 and a plurality of data lines 68 extending from the data line driving circuit 62 are provided in the display unit 5 , and pixels 40 are provided correspondin...

no. 2 Embodiment approach

[0157] Next, a second embodiment of the present invention will be described.

[0158] FIG. 10 is a circuit configuration diagram of a pixel 240 included in the electrophoretic display device in the second embodiment. Also, in Figure 10, with figure 2 The same symbols are attached to the same constituent elements, and their detailed descriptions are appropriately omitted.

[0159] A pixel 240 shown in FIG. 10 includes a driving TFT 41 , a latch circuit (storage circuit) 270 , a switch circuit 80 , a pixel electrode 35 , an electrophoretic element 32 , and a common electrode 37 . In addition, because the configuration other than the latch circuit 270 (the driving TFT 41, the switch circuit 80, etc.) is the same as that shown in figure 2 The pixel 40 is the same, so the latch circuit 270 will be mainly described below.

[0160] The latch circuit 270 includes a transfer inverter 270 t , a feedback inverter 270 f , and a switching transistor 75 .

[0161] transfer inverter 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com