Method for extracting peony seed oil

A technology of peony seed oil and peony seeds, applied in edible oil/fat, food preparation, food science, etc., can solve the problems of low extraction efficiency, cumbersome steps, and few researches on the extraction of peony seed oil, and achieve simple extraction and separation methods , The effect of extracting complete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

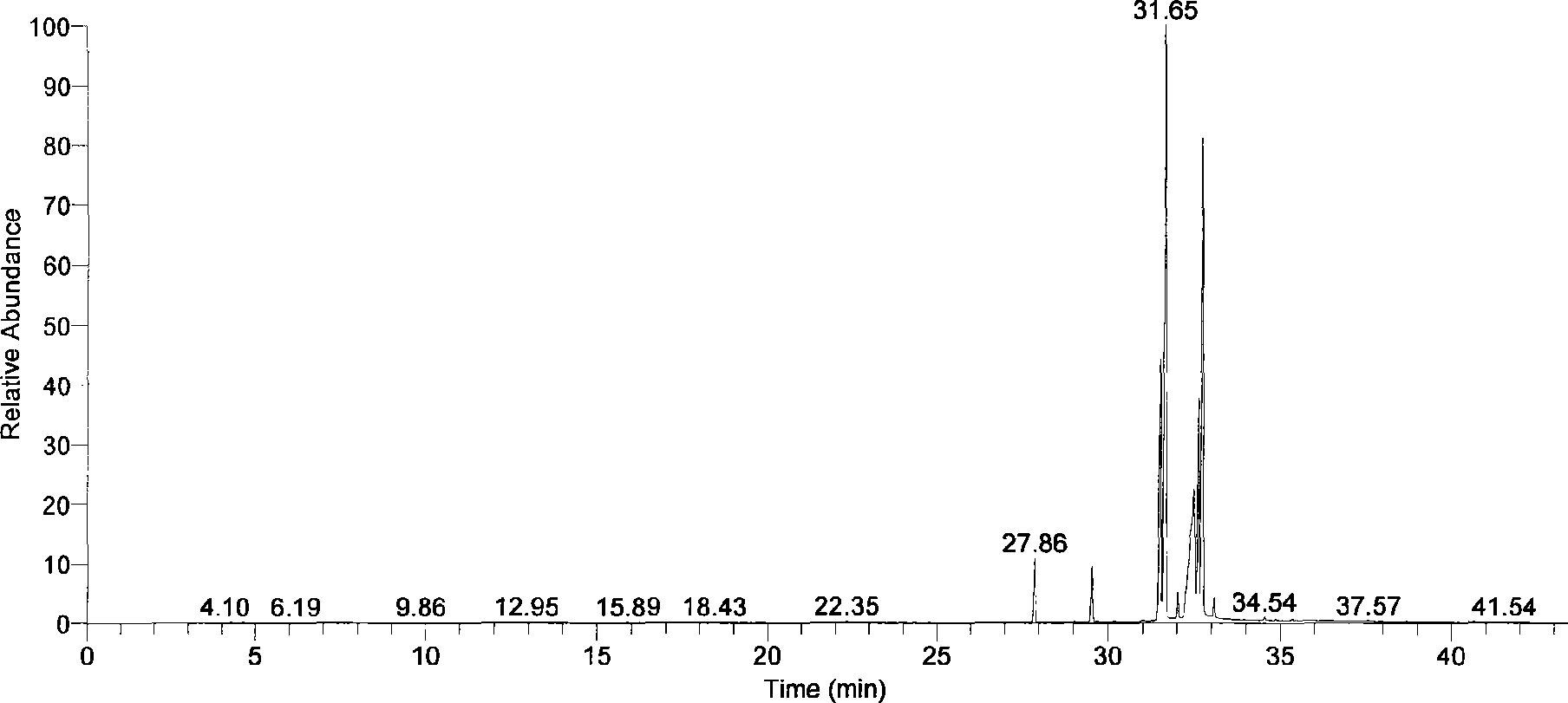

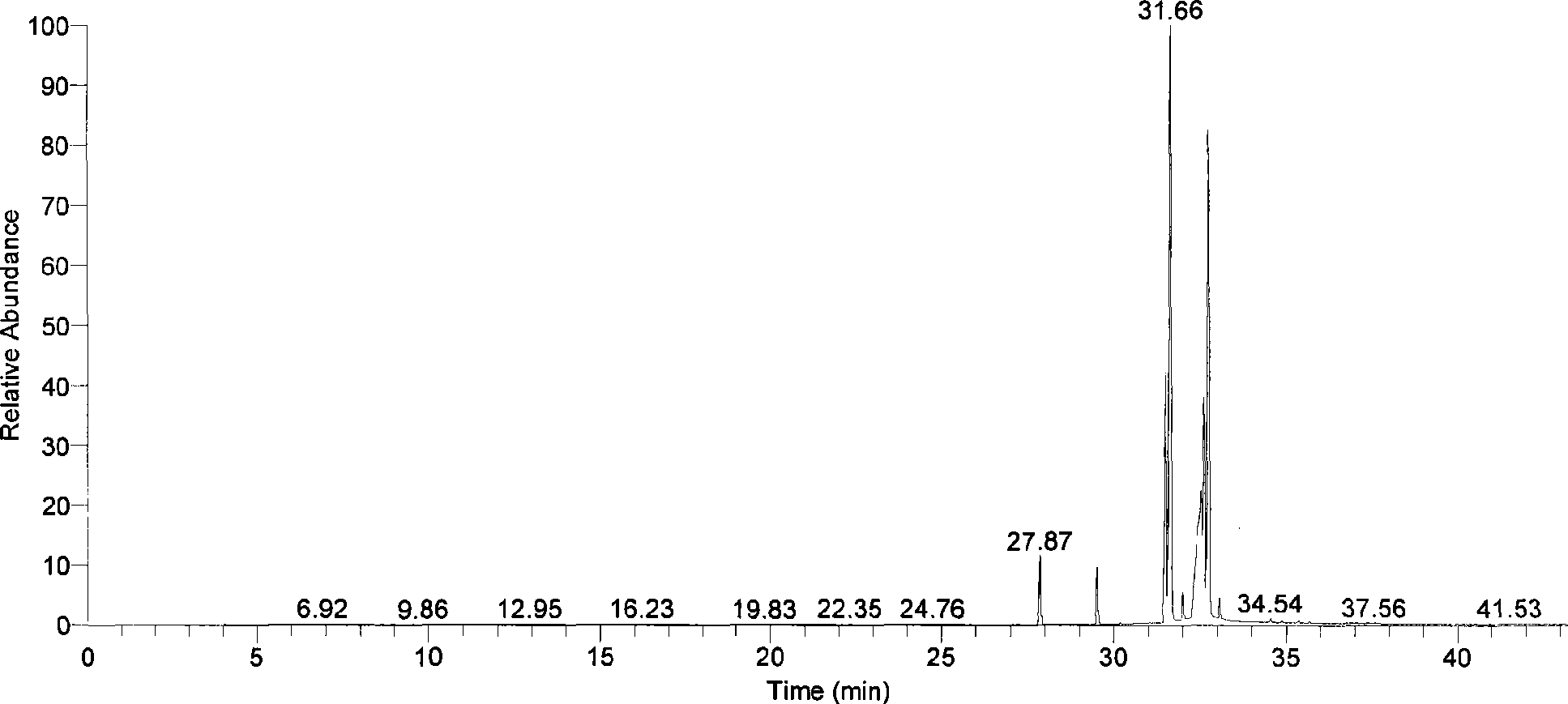

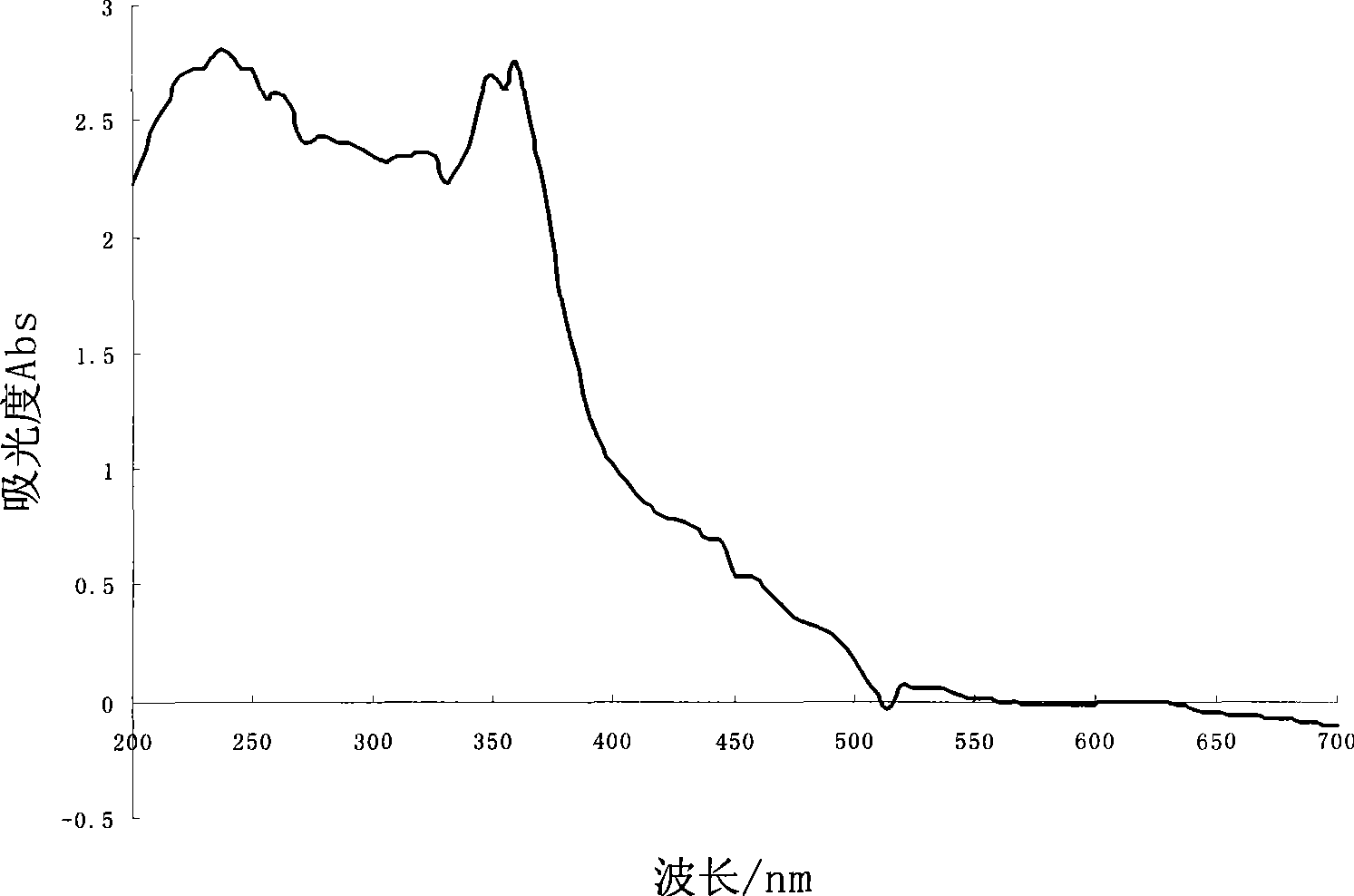

[0014] Embodiment 1, supercritical CO 2 Peony Seed Oil Extraction

[0015] The model of the supercritical extraction instrument used in the present invention is HA121-50-01, and its device diagram is as follows Figure 5 shown. The method for extracting peony seed oil provided by the invention specifically comprises the following steps:

[0016] 1) Dry the peony seeds in an oven at 60°C for 48 hours, put them into a grinder and grind them into powder, sieve peony seed powders with different particle sizes, and take 20-60 mesh particle sizes for later use.

[0017] 2) Weigh 200g of raw material, put it into the extraction kettle, turn on the cold cycle refrigeration, and open the air valve.

[0018] 3) Set the temperature of separation I and separation II in the extraction tank to 45°C, 40°C, and 35°C, respectively.

[0019] 4) When the refrigeration equipment stops working, turn on the high-pressure pump and open valves 1 and 3.

[0020] 5) When the pressure reaches 30MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com