Adsorbent thermal desorption regeneration method and device thereof

A regeneration device and adsorbent technology, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of poor regeneration performance of adsorbents, high purification operation costs, secondary pollution, etc., to simplify operations and save money. Operating costs and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

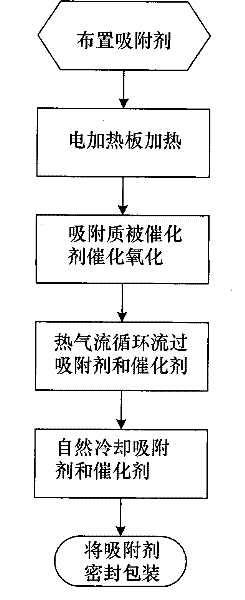

[0036] (1) Arrange the adsorbent containing the adsorbate on a porous electric heating plate.

[0037] Granular activated carbon impregnated with manganese oxide was selected as the adsorbent, the manganese oxide load was 2%, and the adsorbent was in bulk, that is, in the form of the adsorbent packaging bag structure commonly used in households. Arrange the adsorbent on the electric heating plate of the thermal desorption regeneration device of the present invention.

[0038] (2) Turn on the electric heating plate and keep the temperature at 270° C. to desorb the adsorbate on the surface of the adsorbent.

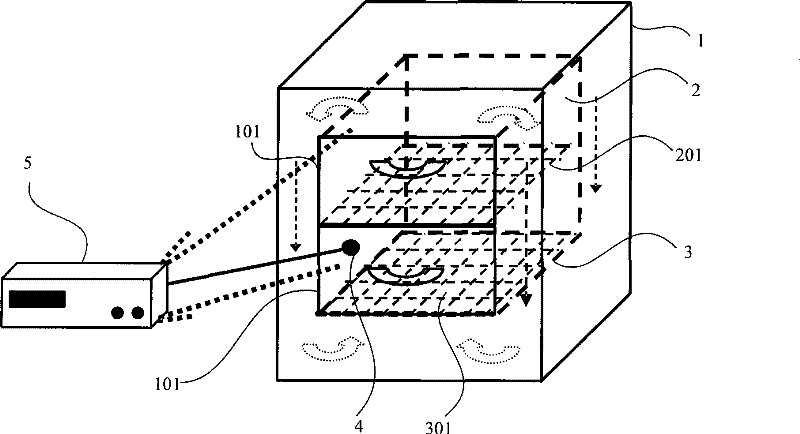

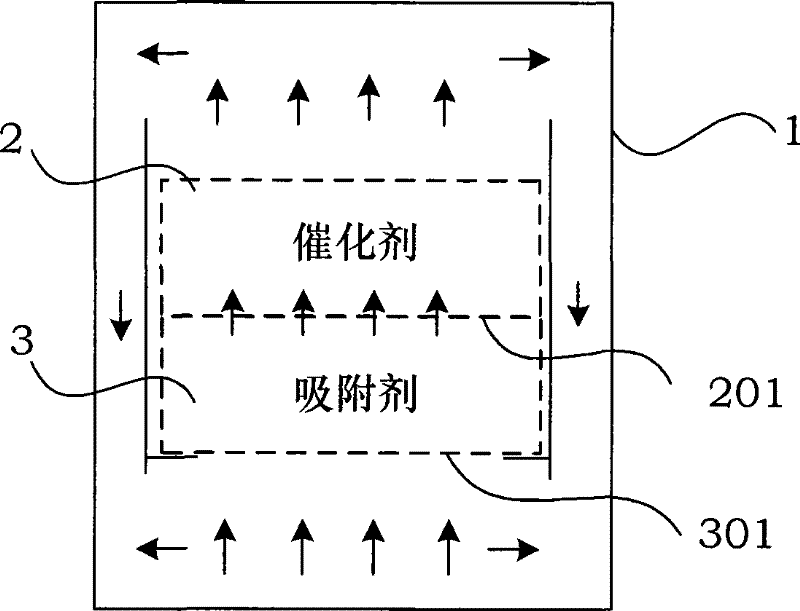

[0039]Use the temperature controller 5 installed outside the box 1 to heat the porous electric heating plate of the lower cavity 3 to increase the temperature of the adsorbent to 270°C. The thermocouple 4 is used to monitor the temperature in the lower cavity 3 and feedback Give the temperature controller 5 to keep the temperature in the lower chamber 3 at 270°C.

[0040]...

Embodiment 2

[0047] (1) Arrange the adsorbent containing the adsorbate on a porous electric heating plate.

[0048] Granular activated carbon impregnated with manganese oxide was selected as the adsorbent, the manganese oxide load was 9%, and the adsorbent was in bulk, that is, the adsorbent packaging bag structure commonly used in households. Arrange the adsorbent on the electric heating plate of the thermal desorption regeneration device of the present invention.

[0049] (2) Turn on the electric heating plate and keep the temperature at 200° C. to desorb the adsorbate on the surface of the adsorbent.

[0050] Use the temperature controller 5 installed outside the box 1 to heat the porous electric heating plate of the lower chamber 3 to raise the temperature of the adsorbent to 200°C. The thermocouple 4 is used to monitor the temperature in the lower chamber 3 and feed back Give the temperature controller 5 to keep the temperature in the lower chamber 3 at 200°C.

[0051] (3) The desor...

Embodiment 3

[0058] (1) Arrange the adsorbent containing the adsorbate on a porous electric heating plate.

[0059] Granular activated carbon impregnated with manganese oxide was selected as the adsorbent, the manganese oxide load was 5%, and the adsorbent was in bulk, that is, in the form of the adsorbent packaging bag structure commonly used in households. Arrange the adsorbent on the electric heating plate of the thermal desorption regeneration device of the present invention.

[0060] (2) Turn on the electric heating plate and keep the temperature at 230°C to desorb the adsorbate on the surface of the adsorbent.

[0061] Use the temperature controller 5 installed outside the box 1 to heat the porous electric heating plate of the lower cavity 3 to raise the temperature of the adsorbent to 230°C. The thermocouple 4 is used to monitor the temperature in the lower cavity 3 and feedback Give the temperature controller 5 to keep the temperature in the lower chamber 3 at 230°C.

[0062] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com