Method for preparing novel carbon nano-fiber platinum catalyst

A technology of nano-carbon fiber and platinum catalyst, which is applied in the field of nano-composite materials and electrocatalysis, which can solve the problems of large raw materials, waste, and environmental pollution, and achieve the effects of fast response, avoiding environmental pollution, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

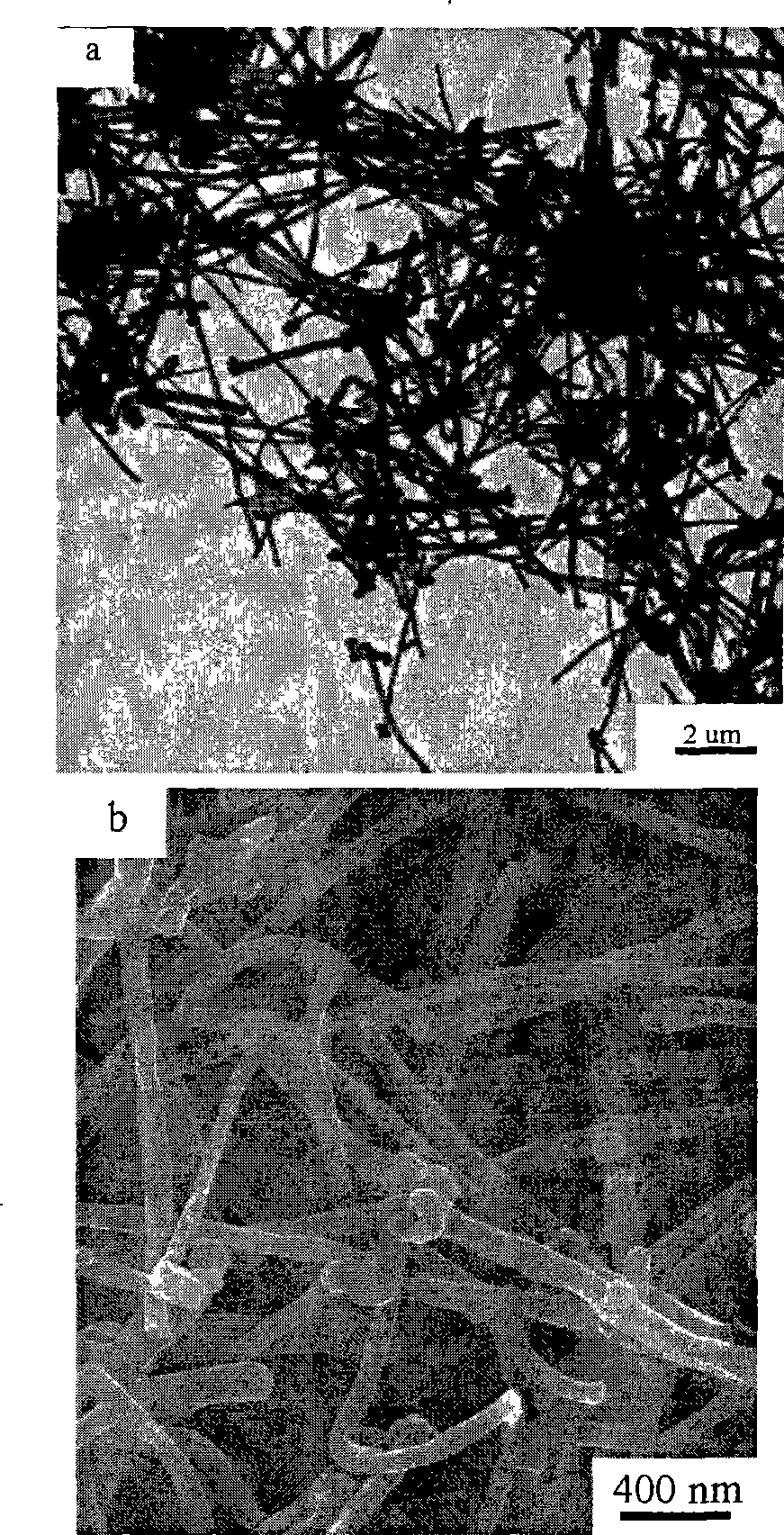

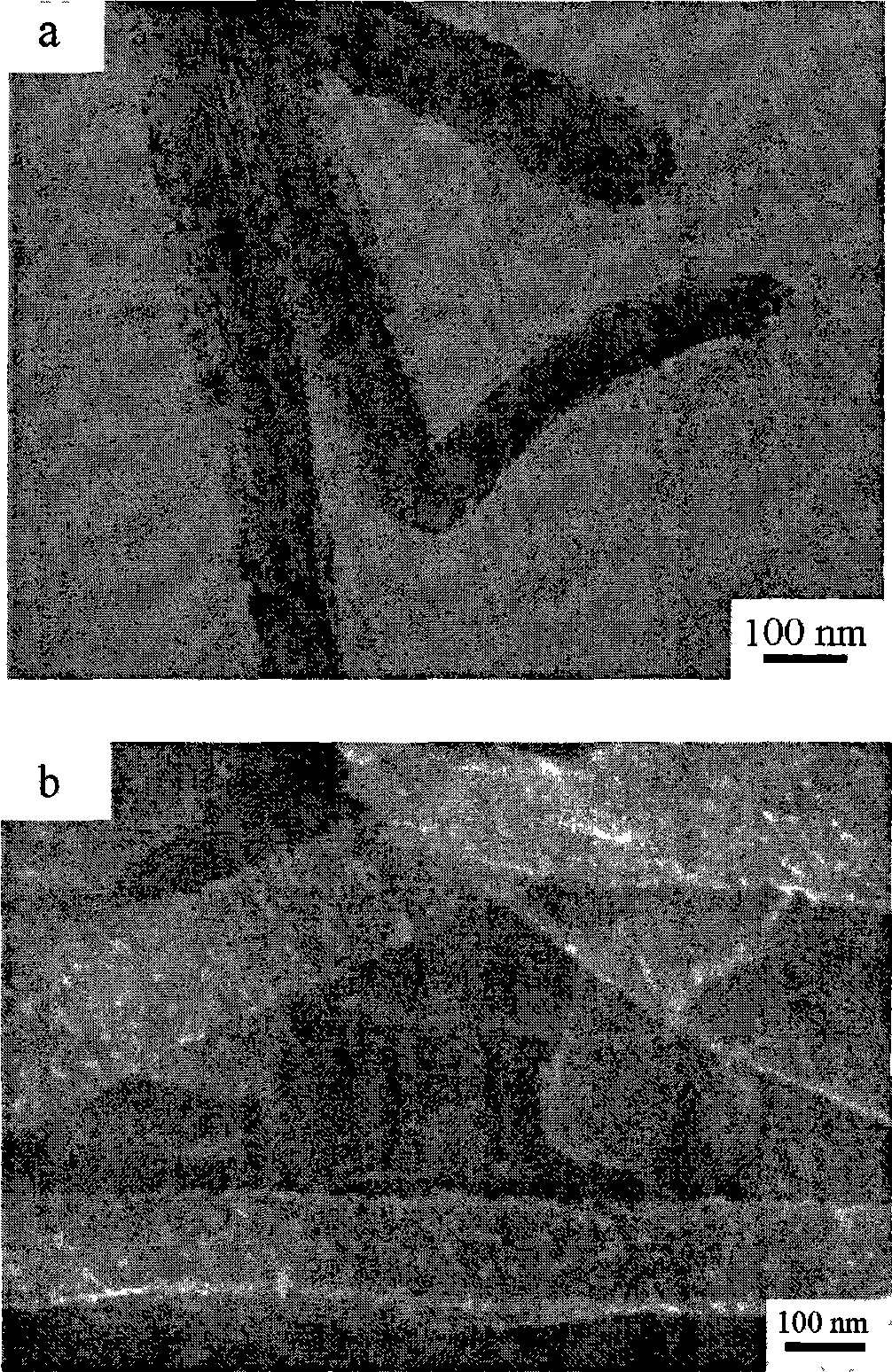

Image

Examples

Embodiment 1

[0013] 1. Surface pretreatment of carbon nanofibers (provided by Showa Denko Co.Ltd. in Japan): 2.02g of carbon nanofibers were added to a three-necked flask, and 180ml of H 2 SO 4 , and then slowly drop 60ml of HNO 3 ; Put the three-necked flask into an oil bath at 60°C, and subject it to acid reflux for 5 hours; cool the three-necked flask with carbon nanofibers and mixed acid at room temperature; repeatedly filter and wash for 3 to 5 times until the pH value reaches neutral. Vacuum drying to obtain modified carbon nanofibers with good surface hydrophilicity.

[0014] 2. Nano-carbon fiber-supported platinum catalyst: weigh 60 mg of treated nano-carbon fiber and dissolve it in 75 ml of ethylene glycol (EG); ultrasonically disperse the EG solution with nano-carbon fiber for 2 hours; take 308ul of H 2 PtCl 6 Standard solution, made into 5ml of H 2 PtCl 6 -EG solution; the H 2 PtCl 6 -EG 5ml solution was transferred into ultrasonically dispersed carbon nanofibers-EG; heat...

Embodiment 2

[0016] 1. Surface pretreatment of carbon nanofibers (provided by Showa Denko Co.Ltd. in Japan): 1g of carbon nanofibers was added to a three-necked flask, and 90ml of H 2 SO 4 ; put the three-necked flask into an oil bath at 100°C, and subject it to acid reflux for 6 hours; cool the three-necked flask with nano-carbon fibers and strong acid at room temperature; repeatedly filter and wash for 3 to 5 times until the pH value reaches neutral. Vacuum drying to obtain modified carbon nanofibers with good surface hydrophilicity.

[0017] 2. Carbon nanofiber supported platinum catalyst: Weigh 80mg of treated nanocarbon fiber and dissolve it in 90ml propylene glycol; ultrasonically disperse the propylene glycol solution in which nanocarbon fiber is dissolved for 2h; take 350ul of H 2 PtCl 6 Standard solution, made into 5ml of H 2 PtCl 6 - propylene glycol solution; H 2 PtCl 6 - 5ml of propylene glycol solution was transferred into ultrasonically dispersed nano-carbon fiber-propy...

Embodiment 3

[0019] 1. Surface pretreatment of carbon nanofibers (provided by Showa Denko Co.Ltd. in Japan): 1g of carbon nanofibers was added to a three-necked flask, and 60ml of H 2 SO 4 , and then slowly drop 60ml of HNO 3 ;Put the three-necked flask in an 80°C oil bath, and subject it to acid reflux for 6 hours; cool the three-necked flask with carbon nanofibers and mixed acid at room temperature; repeatedly filter and wash for 3 to 5 times until the pH value reaches neutral. Vacuum drying to obtain modified carbon nanofibers with good surface hydrophilicity.

[0020] 2. Nano-carbon fiber supported platinum catalyst: Weigh 100mg of treated nano-carbon fiber and dissolve it in 90ml ethylene glycol; ultrasonically disperse the ethylene glycol solution with nano-carbon fiber dissolved in it for 2 hours; take 400ul of dinitrosodiammine platinum standard Solution, made into 5ml of dinitrosodiammine platinum-ethylene glycol solution; transfer 5ml of dinitrosodiammine platinum-ethylene glyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com