Method for processing electromagnetic wave isolation function of plastic material surface

A technology of plastic materials and processing methods, which is applied to the device for coating liquid on the surface, the metal material coating process, ion implantation plating, etc., and can solve the problems of increased production costs, increased computer weight, and many holes and cracks in the shielding cover, etc. problem, achieve the effect of increasing adhesion and avoiding harm to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

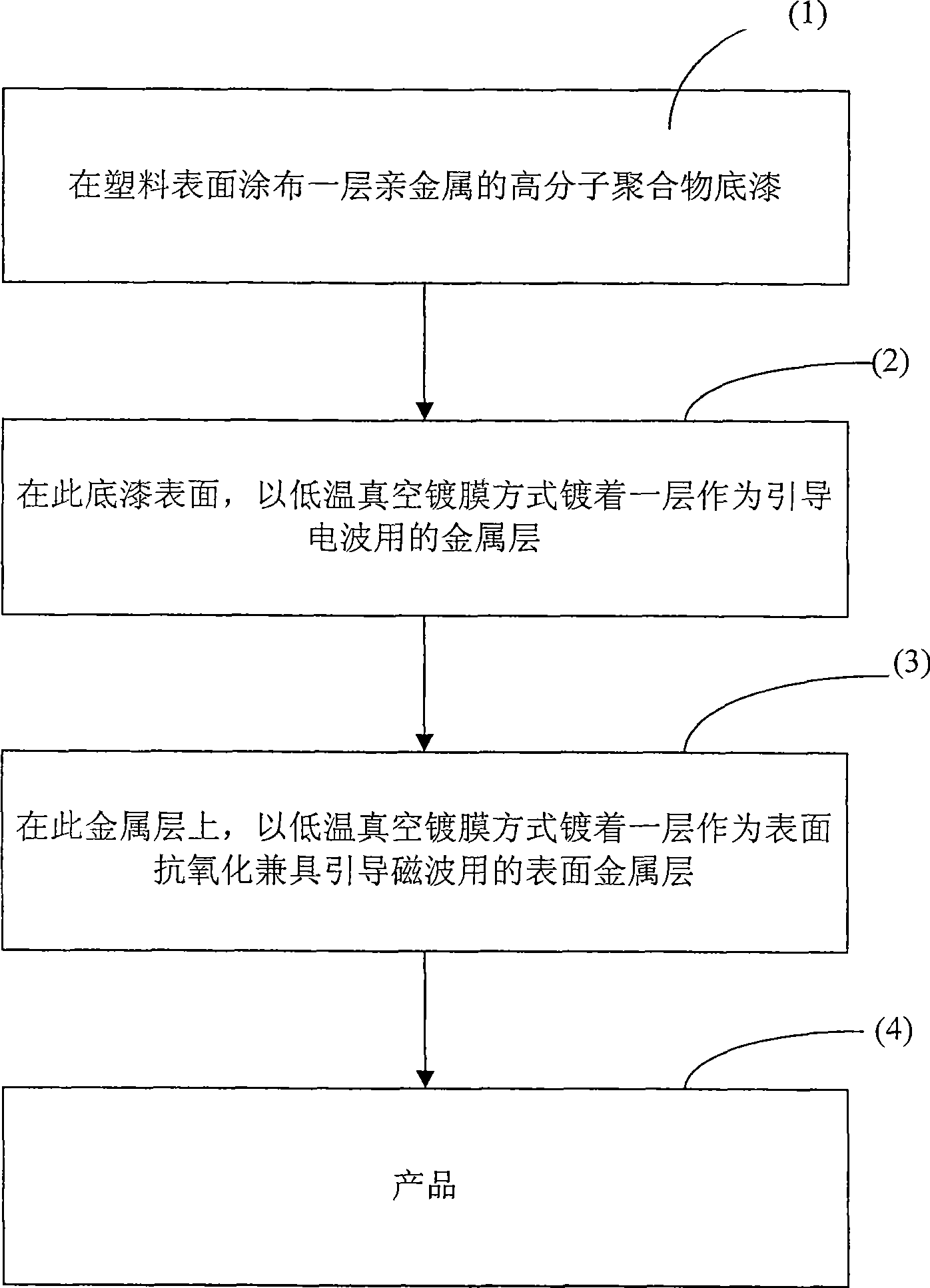

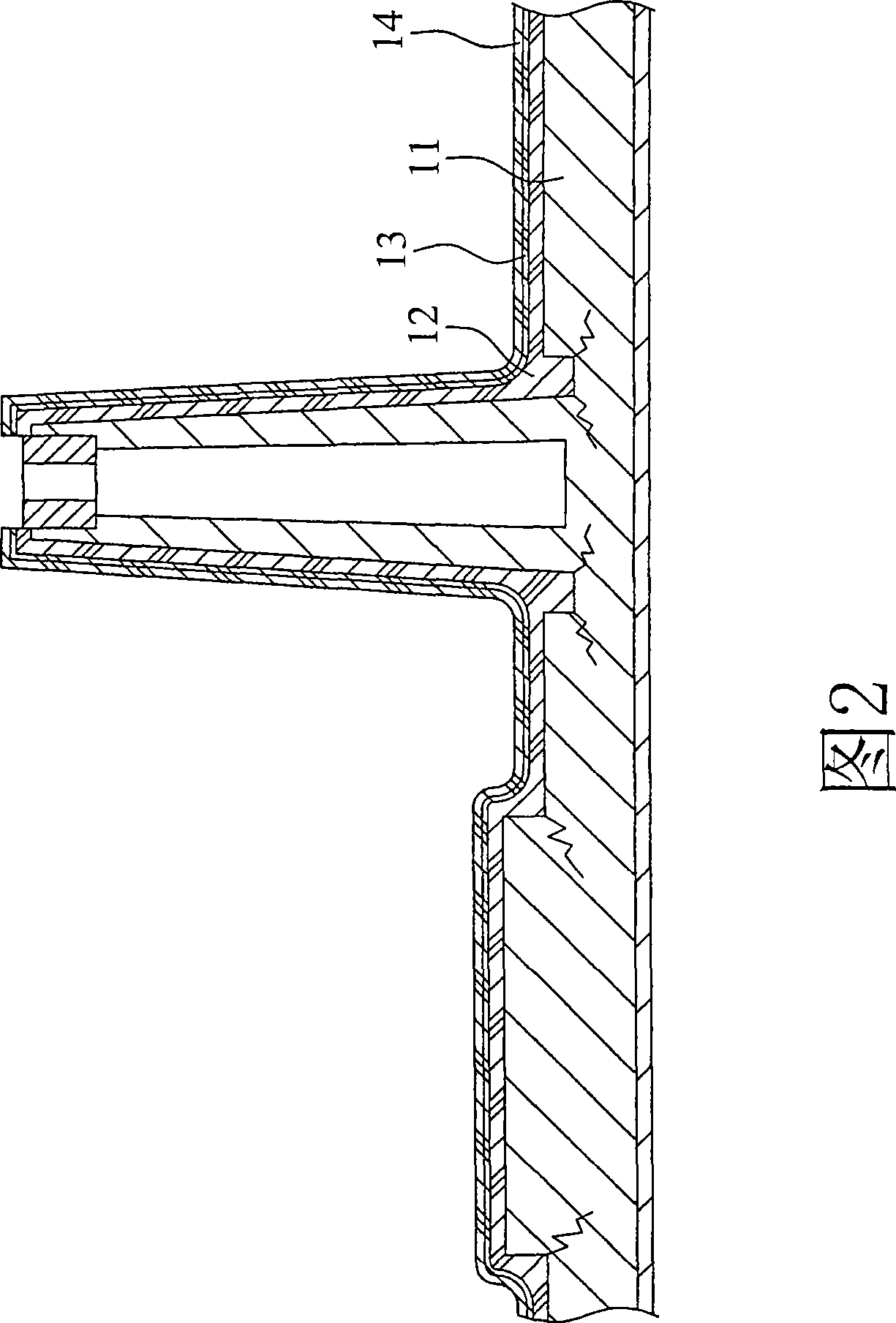

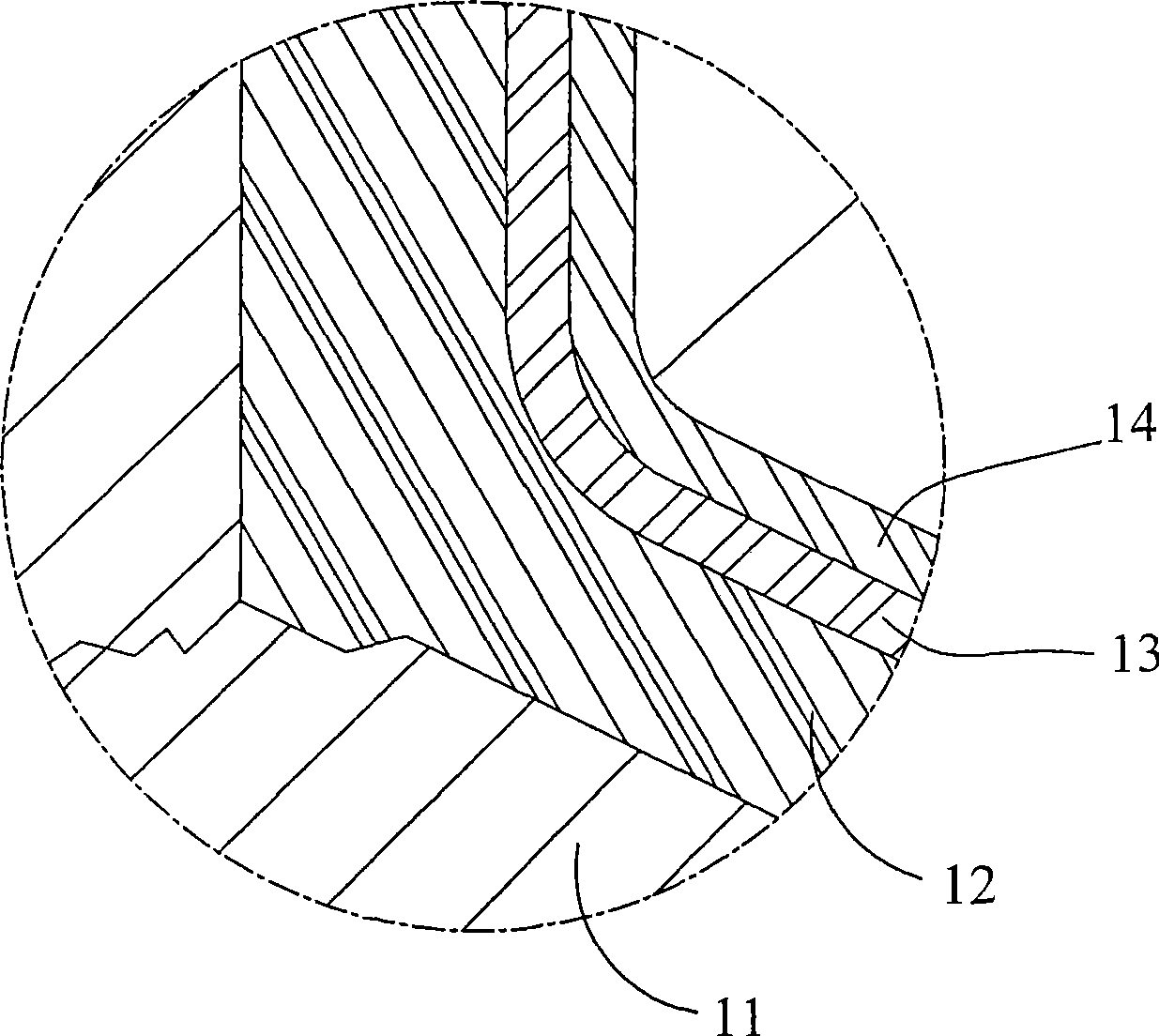

[0018] A treatment method of the electromagnetic wave isolation function on the surface of a plastic material of the present invention, please refer to figure 1 ,figure 2, image 3 As shown, in this method, a metal-friendly polymer primer 12(1) is coated on the surface of a plastic casing 11 of an electronic device by spraying paint, and then, after the primer 12 is dry, the The surface of the primer 12 is coated with a layer of metal film 13(2) as a guide for radio waves by low-temperature vacuum coating, and then coated with a layer of metal film 13(2) as a surface for anti-oxidation and guiding magnetic waves by the same low-temperature vacuum coating. The metal film 14 (3) and finally the finished product (4).

[0019] Through the sealing effect of the metal-friendly polymer primer 12, a film that strengthens the plastic surface of the casing 11 can be obt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap