Multi-level depressurization collector for traveling wave tube

A technology of traveling wave tubes and collectors, which is applied in the field of multi-stage step-down collectors, can solve the problems of poor adaptability of insulating materials, hindering the application of traveling wave tubes, and increasing the volume of collectors, and achieves light weight, easy processing and assembly. The effect of simple process and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

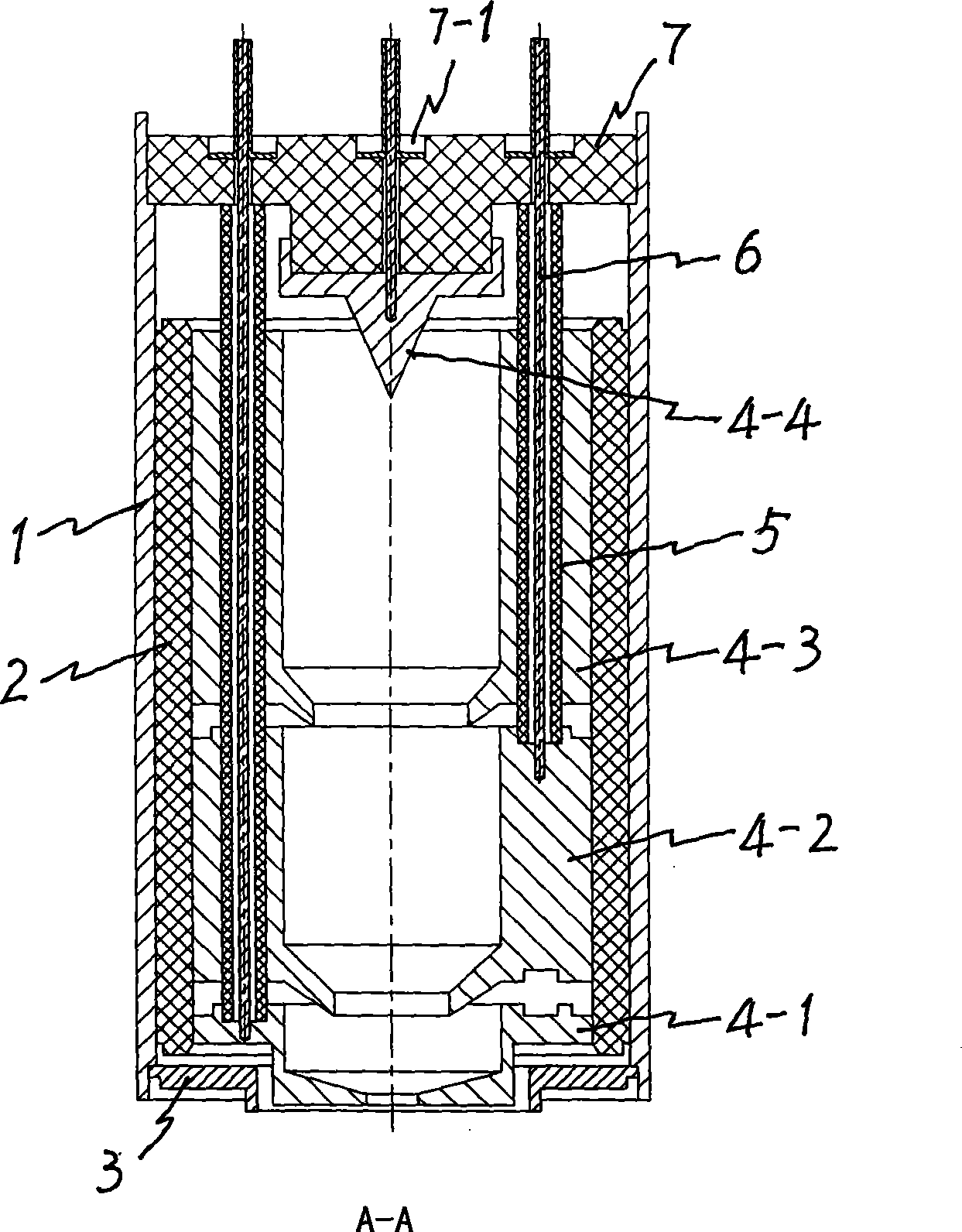

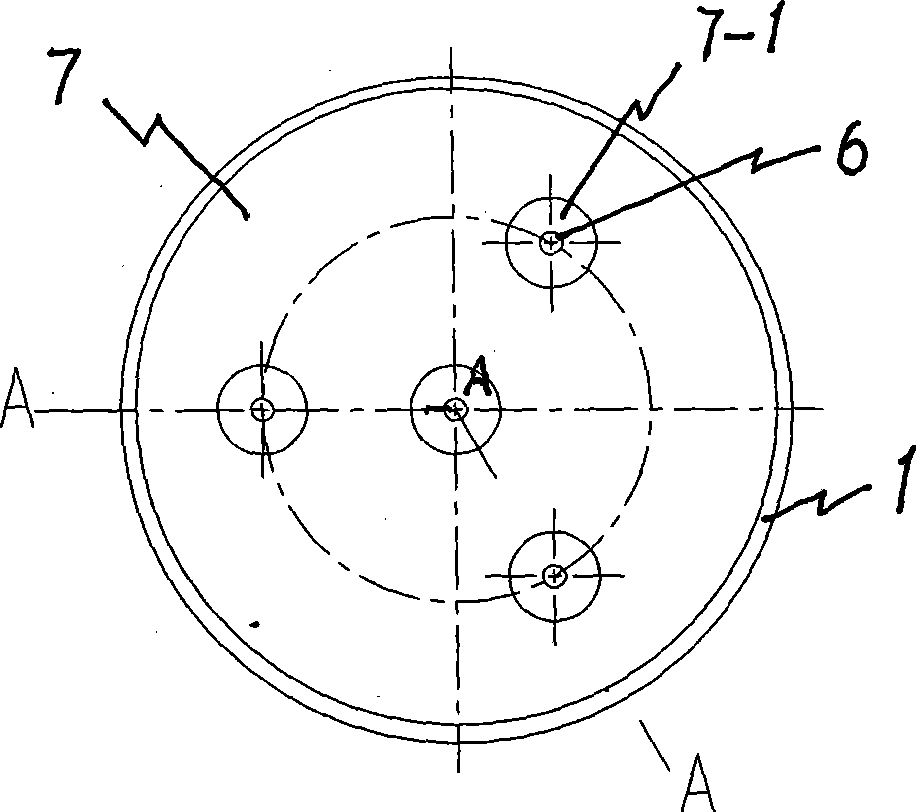

[0012] Embodiment 1: Taking the 4-stage step-down collector pole for a traveling wave tube as an example, the inner and outer diameters of the collector shell 1 are φ42mm and φ45mm respectively, and the length is 90mm; the insulating cylinder 2, the insulating back cover 7 and the insulating conduit 5 are all Using conventional ceramic insulators, the inner and outer diameters of the insulating cylinder 2 are φ36mm and φ42mm respectively, the axial length is 65mm, the outer diameter of the insulating back cover 7 is φ43mm, the total thickness is 12mm, and the center hole of the power line lead-out hole 7-1 is located at the axis , The remaining 3 holes are set according to the distance of 120° and the radius R13.5mm. The electrode holder 7-2 has a diameter of φ18mm and a height of 6mm; the outer diameter of the insulating conduit 5 is φ5mm and the tube wall thickness is 2mm; the first-level electrodes 4-1, 4-2, 4-3 main bodies have an inner diameter of φ19mm, an outer diameter ...

Embodiment 2

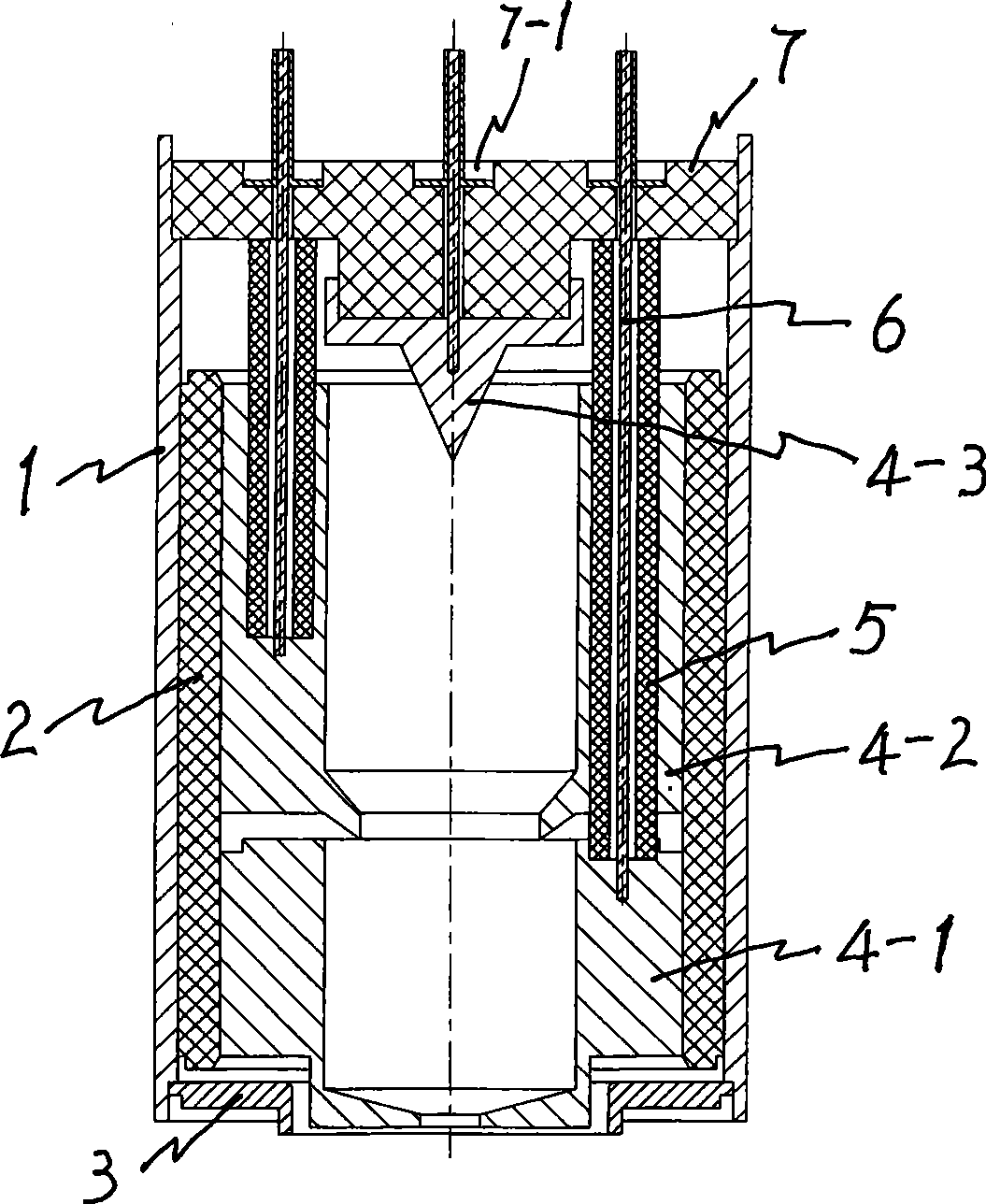

[0013] Embodiment 2; image 3 It is a schematic diagram of the structure of the 3-stage step-down collector of this embodiment; the inner and outer diameters of the collector shell 1 and the insulating cylinder 2 are the same as those of the embodiment 1, and the axial lengths are 76mm and 51mm respectively, and the insulating cylinder 2 is used in this embodiment. Beryllium oxide (BeO) ceramics; the second level electrode 4-2 and the third level electrode 4-3 are respectively the same as the third level electrode 4-3 and the fourth level electrode 4-4 in embodiment 1, and the first level electrode 4-1 The inner diameter of the main body is φ19mm, the outer diameter is also φ36mm, and the axial length is 20mm; the outer diameter and wall thickness of the front cover 3, the insulating conduit 5, the outer diameter and total thickness of the insulating back cover 7, and the middle electrode seat 7 The diameter of -2 is also all identical with embodiment 1, and 3 power line lead-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com