Mass flux control device

A technology of mass flow control and DC power supply, applied in flow control, non-electric variable control, control/regulation system, etc., can solve problems such as poor anti-interference ability, and achieve the effect of enhancing anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

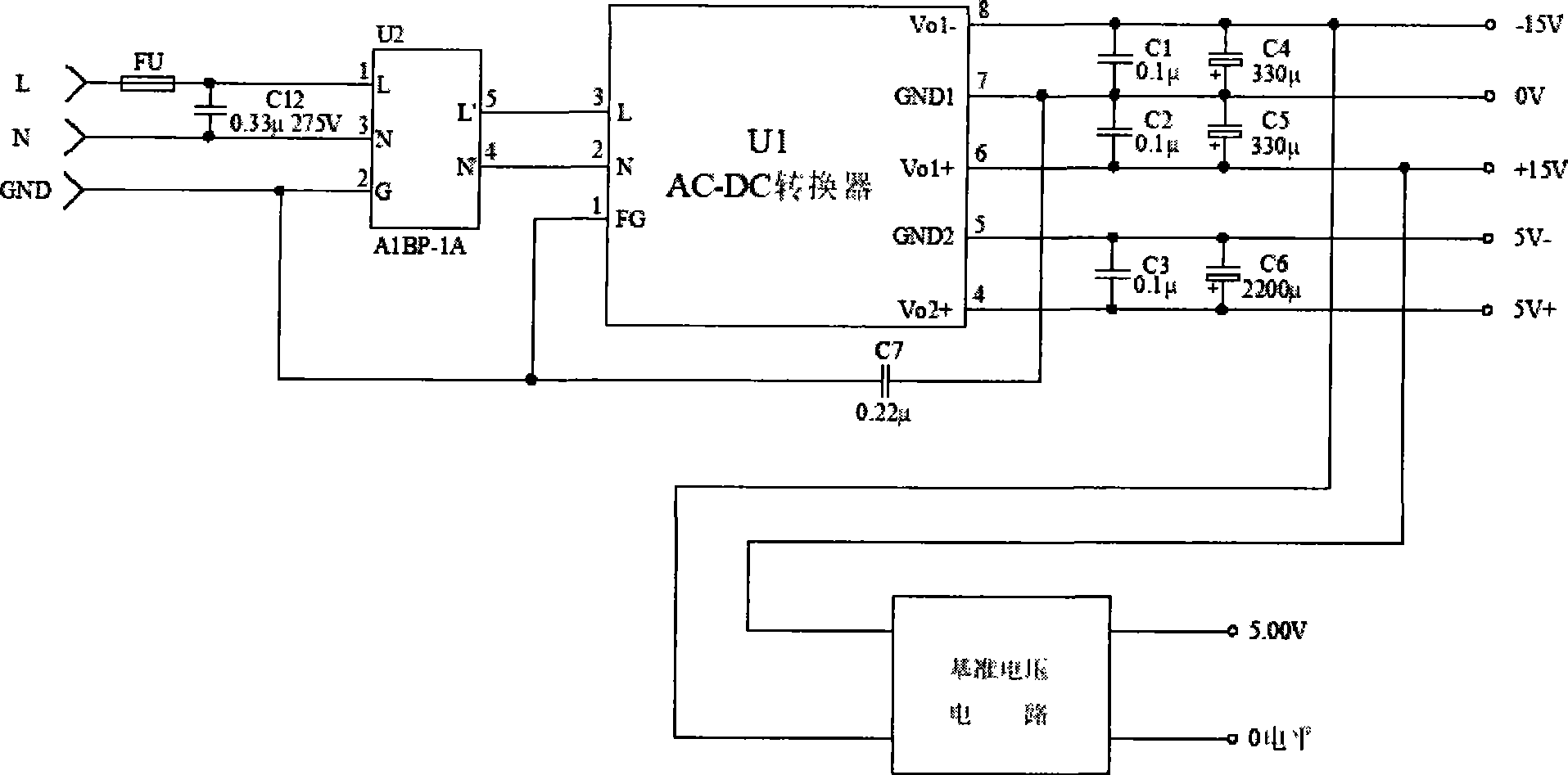

[0013] A preferred embodiment of the mass flow control device of the present invention includes a power supply and a display module, and the power supply and display module include a power supply circuit.

[0014] like figure 1 shown. The power circuit includes an anti-interference capacitor C12, and the anti-interference capacitor C12 is connected between the live line L and the neutral line N of the AC input end of the power circuit.

[0015] The anti-interference capacitor C12 is a metallized polypropylene film capacitor. Metallized capacitors are made by depositing a very thin metal film on the capacitor by vacuum evaporation. Its main feature is that it has a self-healing effect. When the capacitor breaks down due to dielectric short circuit, an arc current will be generated immediately at the breakdown point, and the current density is concentrated in the center of the breakdown point. The heat generated by this current is enough to volatilize the metal coating near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com