Spiral trumpet shaped microwave energy reclaiming antenna and array microwave heating apparatus thereof

A technology of energy-feeding antenna and horn antenna, which is applied in the field of industrial microwave heating, can solve the problems of shortening the working life of magnetron, single mode, and poor effect, so as to reduce the mutual coupling phenomenon of electromagnetic waves at ports, improve life and reliability, The effect of reducing equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

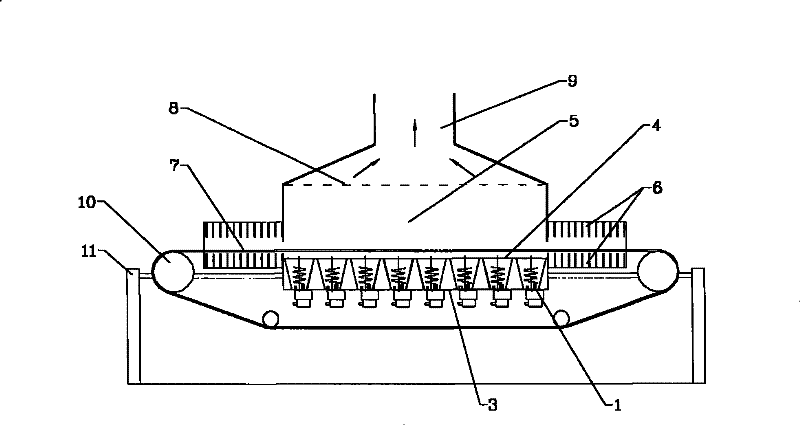

[0018] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described

[0019] The specific parameters and dimensions of each part of this implementation case are as follows:

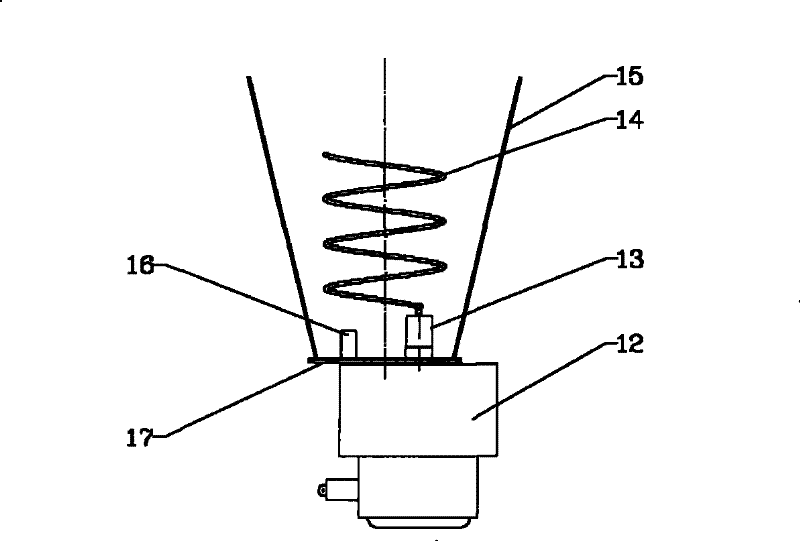

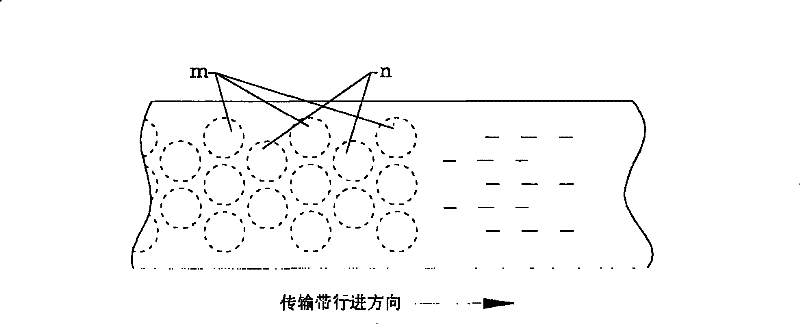

[0020] This implementation case is designed according to the operating frequency of the microwave source is 2450MHz, the helical horn antenna (see figure 2 The shell in ) is made of aluminum or stainless steel, the radius of the horn antenna base plate 17 is 42mm, the horn mouth radius at the top of the tapered horn cylinder body 15 is 80mm, and the height of the cone horn cylinder 15 is 170mm; the spiral radius of the helical antenna 14 is 32mm, The helical wire radius of the helical antenna 14 is 2 mm, the pitch is 40 mm, and the number of turns is 3.5; the diameter of the magnetron output antenna head 13 is 17 mm, the height from the bottom plate is 6 mm, and the distance from the center to the horn axis is 21 mm; the radius of the matching pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com