Method and apparatus for preparing synthesis gas by natural gas-carbon dioxide reforming

A carbon dioxide and natural gas technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of complicated equipment, difficult heating of the reactor, and carbon deposition on catalysts, and achieve the effect of avoiding potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

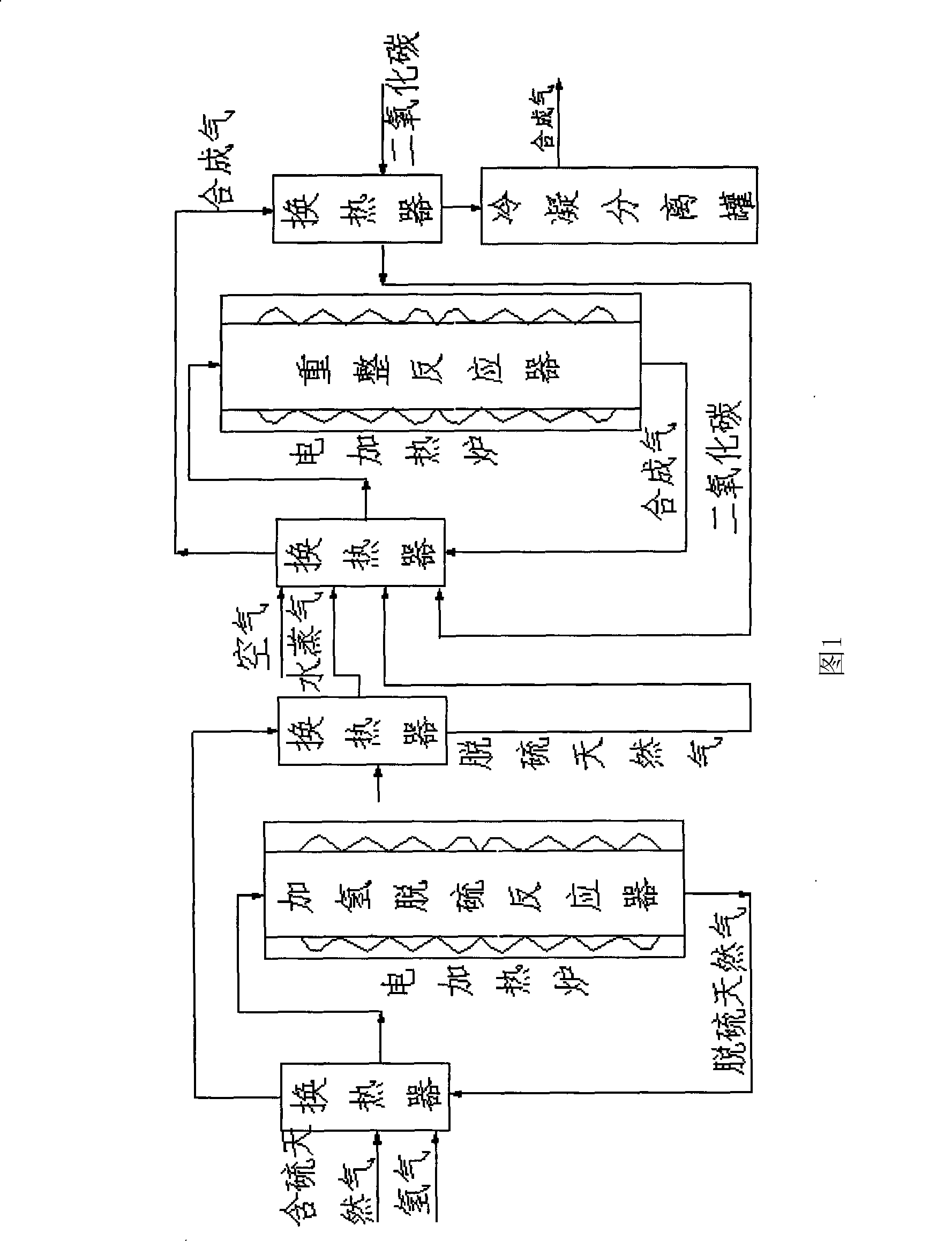

[0036] In this embodiment, various reaction components are set with reference to the devices and processes shown in the accompanying drawings.

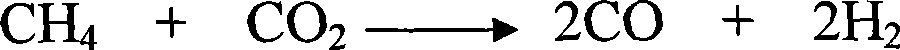

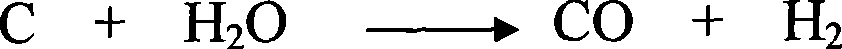

[0037] Preheat sulfur-containing natural gas and hydrogen at a ratio of 1:0.014 to 200°C and send them to the hydrodesulfurization reactor as a desulfurization unit. The cobalt-molybdenum catalyst and the zinc oxide adsorbent are respectively 200g, and the bed heights are 300mm and 350mm respectively. The reaction temperature is 315°C and the pressure is 0.2Mpa. Desulfurized natural gas (sulfur content 0.7ppm) is preheated together with carbon dioxide gas and water vapor at a ratio of 1:1.4:0.04, and then added from the upper part of the reforming reactor. The reforming reactor is equipped with 300g of nickel-based catalyst, and the bed The height is 300mm, the reaction temperature is 850°C, and the reaction pressure is 0.2MPa. After recombination and synthesis, carbon monoxide and hydrogen are output after heat exchange, cooling and ...

Embodiment 2

[0045] According to the process method of Example 1, the desulfurized natural gas, carbon dioxide gas, and water vapor are preheated together with the ratio of 1:1.2:0.04 and then added from the upper part of the reforming reactor, and the synthesized gas is composed of: H 2 43.9%, CO46.5%, CH 4 1.3%, CO 24.2%, H 2 O4.1%

Embodiment 3

[0047] According to the process method of Example 1, the desulfurized natural gas, carbon dioxide gas, and water vapor are preheated together with the ratio of 1:1.0:0.04 and then added from the upper part of the reforming reactor, and the synthesized gas is composed of: H 2 47.3%, CO 46.0%, CH 4 1.7%, CO 2 2.3%, H 2 O2.7%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com