Naphthol novolac epoxy resin and preparation method thereof

A technology of naphthol novolac epoxy resin and naphthol novolac resin, which is applied in the field of naphthol novolac epoxy resin and its preparation, and can solve problems such as no substantive progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

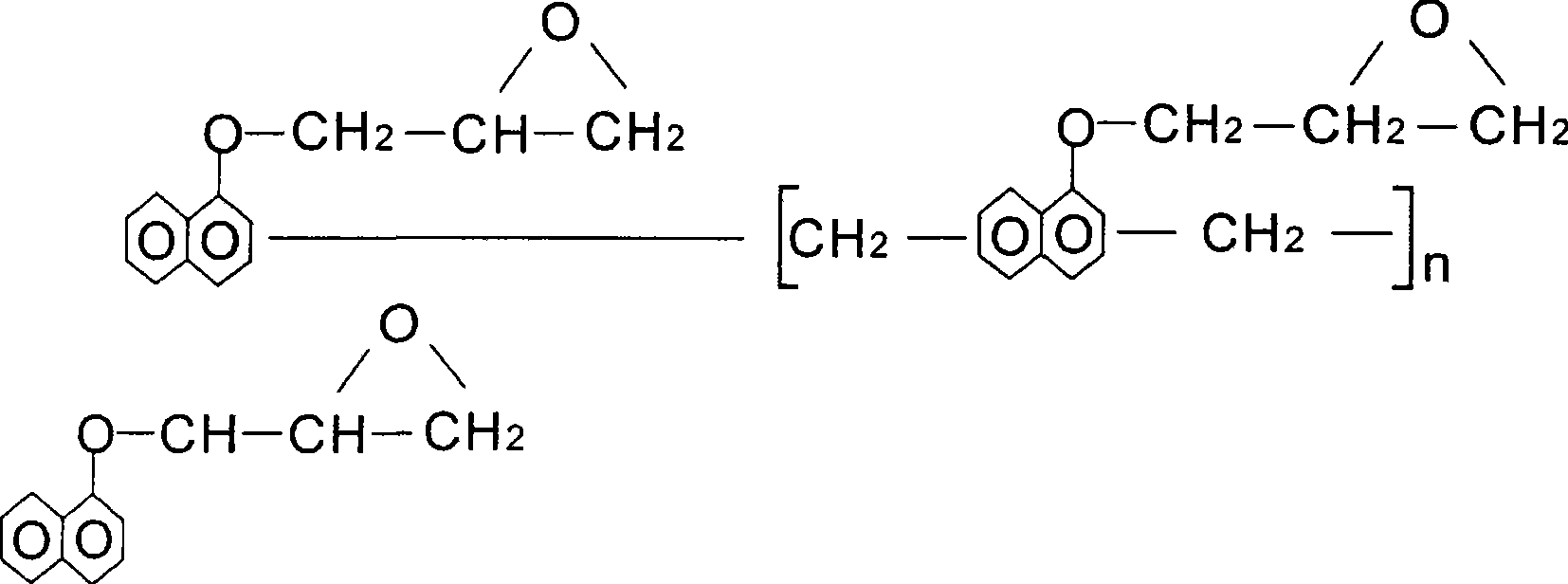

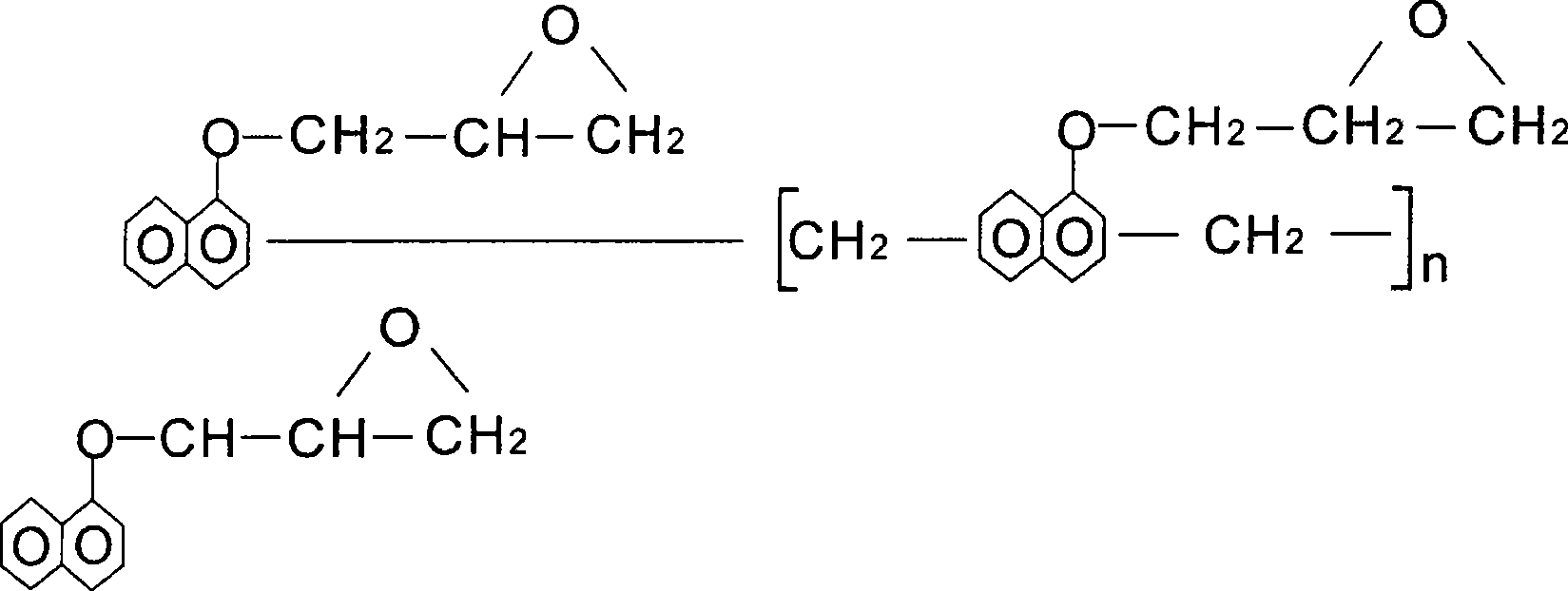

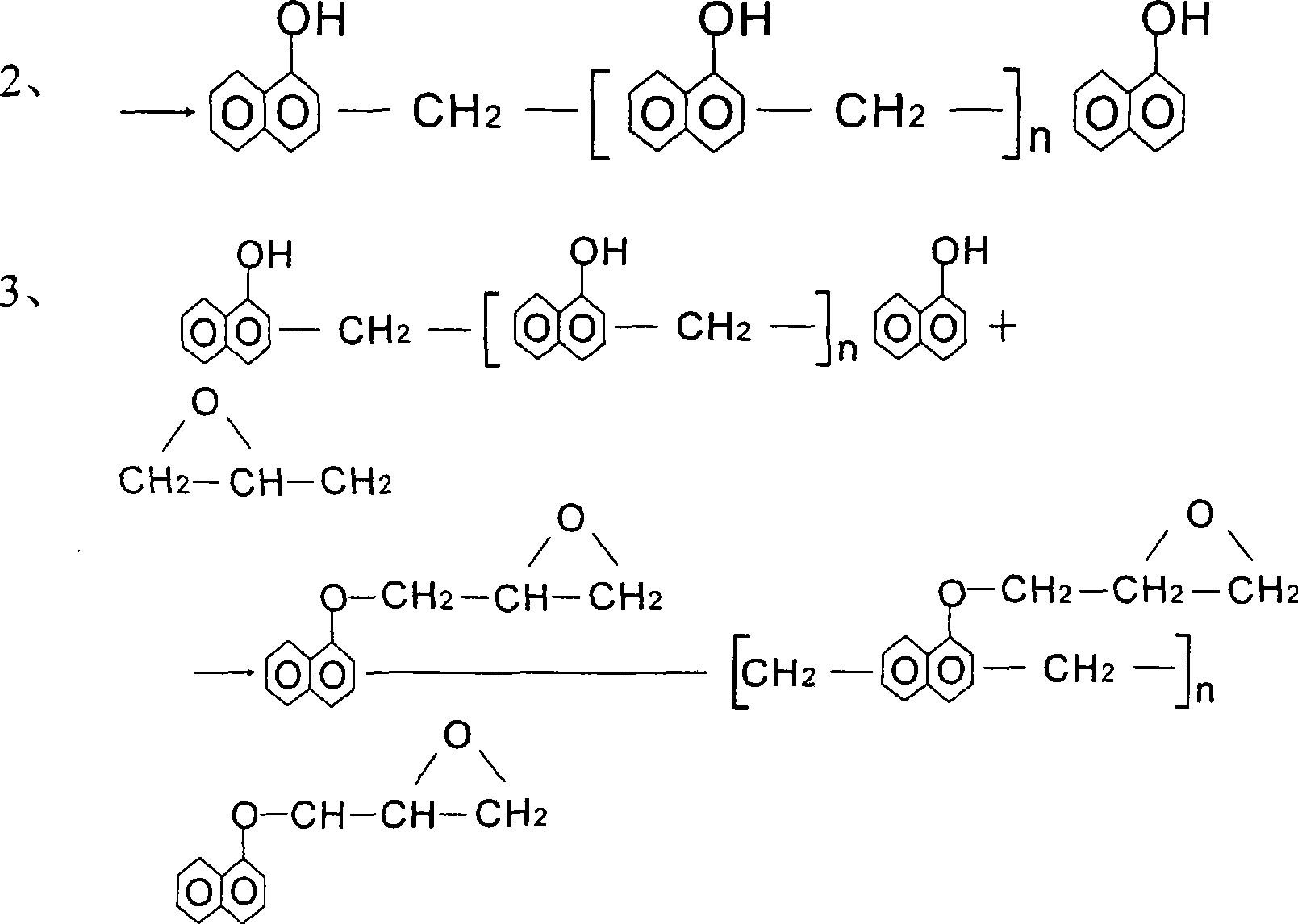

Image

Examples

Embodiment 1

[0040] The preparation method of naphthol novolac epoxy resin:

[0041] 1. Pump 144Kg of methylnaphthol into the reaction kettle, add 4Kg of sulfuric acid as a phenolic catalyst, and then heat up to 75°C, add 65Kg of formaldehyde dropwise into the reaction kettle to carry out polycondensation reaction, control the temperature at 80°C, and keep it warm for 8 hours after titration. The temperature is controlled at 105°C;

[0042] 2. Put the above-mentioned polycondensation reactants into waste water after standing for 1 hour, wash with clean water three times, and obtain naphthol phenolic resin after dehydration;

[0043] 3. Add 0.2Kg of epoxy etherification catalyst tetramethylammonium chloride and 600Kg of epoxy chlorohydrin in the above-mentioned naphthol phenolic resin in proportion by mass, and carry out epoxy etherification reaction under the action of epoxy etherification catalyst. The time is controlled at 2 hours, the temperature is at 70°C, and the temperature is rais...

Embodiment 2

[0048] The preparation method of naphthol novolac epoxy resin:

[0049] 1. Pump 144Kg of methylnaphthol into the reaction kettle, add 4.5Kg of phenolic catalyst sulfuric acid, and then raise the temperature to 78°C, add 68Kg of formaldehyde dropwise into the reaction kettle to carry out polycondensation reaction, control the temperature at 85°C, and keep it warm for 10 hours after titration , the temperature is controlled at 108°C;

[0050] 2. Put the above-mentioned polycondensation reactants into waste water after standing for 1 hour, wash with clean water three times, and obtain naphthol phenolic resin after dehydration;

[0051] 3. Add 0.2Kg of epoxy etherification catalyst tetramethylammonium chloride and 650Kg of epoxy chlorohydrin in the above-mentioned naphthol phenolic resin in proportion by mass, and carry out epoxy etherification reaction under the action of epoxy etherification catalyst. The time is controlled at 2.5 hours, the temperature is at 75°C, and the temp...

Embodiment 3

[0056] The preparation method of naphthol novolac epoxy resin:

[0057]1. Pump 144Kg of methylnaphthol into the reaction kettle, add 5Kg of phenolic catalyst sulfuric acid, and then raise the temperature to 80°C, add 70Kg of formaldehyde dropwise into the reaction kettle to carry out polycondensation reaction, control the temperature at 90°C, and keep it warm for 12 hours after titration. The temperature is controlled at 110°C;

[0058] 2. Put the above-mentioned polycondensation reactants into waste water after standing for 1 hour, wash with clean water three times, and obtain naphthol phenolic resin after dehydration;

[0059] 3. Add 0.2Kg of epoxy etherification catalyst tetramethylammonium chloride and 700Kg of epoxy chlorohydrin in the above-mentioned naphthol phenolic resin in proportion by mass, and carry out epoxy etherification reaction under the action of epoxy etherification catalyst. The time is controlled at 3 hours, the temperature is at 80°C, and the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com