Fume exhaust ventilator and range integrated machine

An all-in-one machine and range hood technology, which is applied in the direction of removing lampblack, household stoves, household appliances, etc., can solve the problems of closing the suction port, disturbing the stove, increasing costs, etc., and achieves the solution of outdoor wind backflow, high safety, Effect of preventing water from entering the suction port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

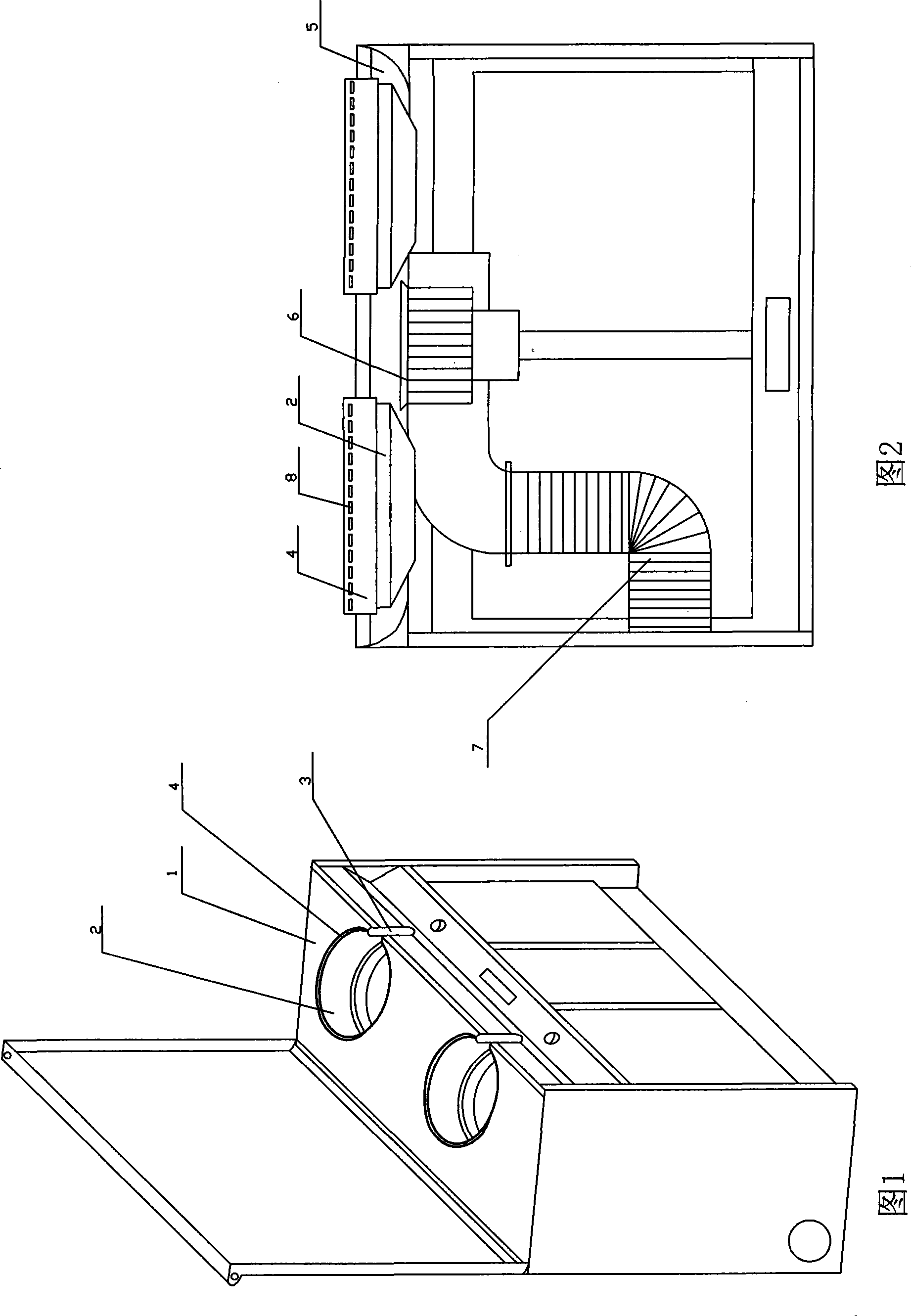

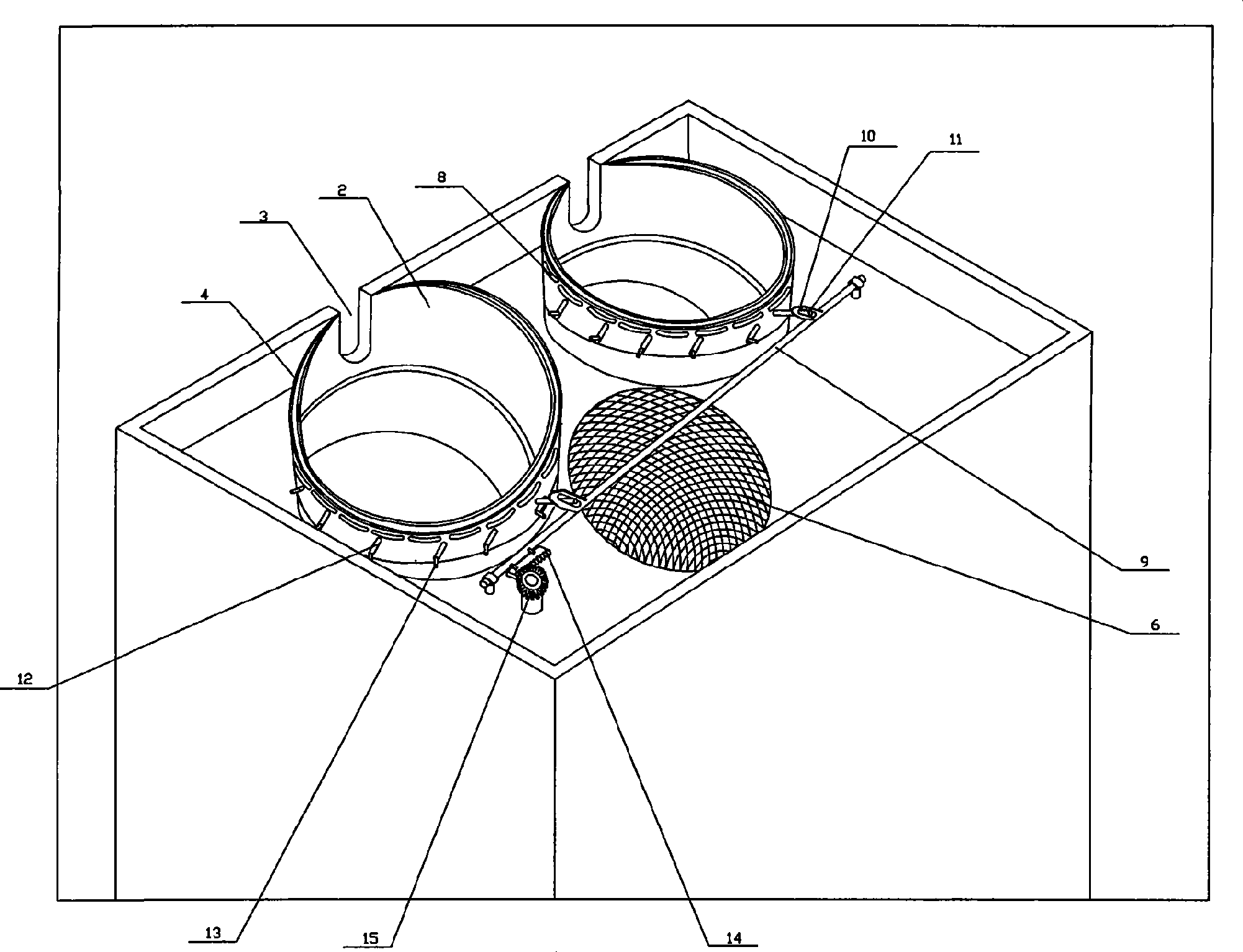

[0028] The range hood integrated machine of the present invention includes a cabinet-type body, the panel 1 of the body is provided with a concave stove hole 2, the bottom plate of the stove hole barrel 2 is provided with a stove, and the stove hole barrel 2 There is a handle hole 3 on the side facing people, the air inlet of the fan 6 is arranged in the gas collecting box 5, and the fan 6 is also connected to the exhaust pipe 7.

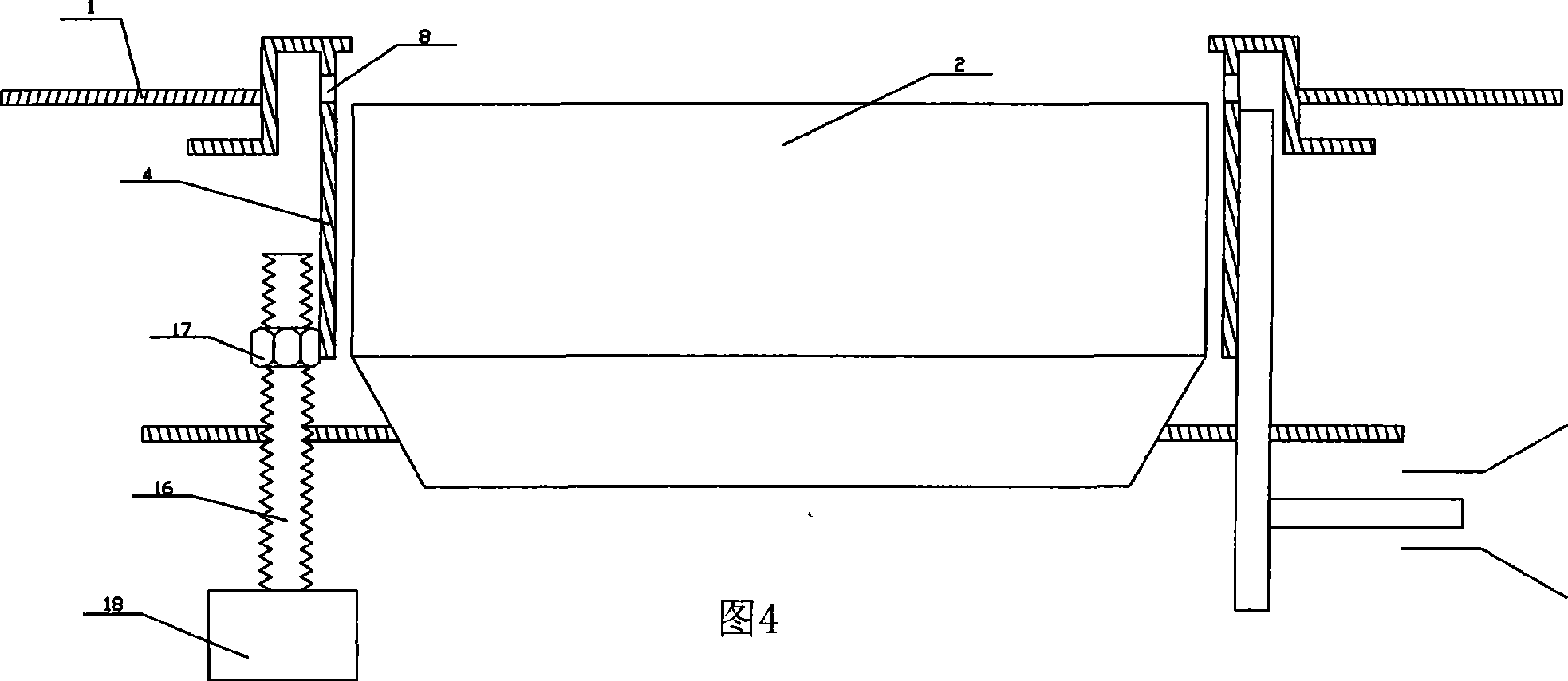

[0029] The lifting ring 4 is slidably connected to the outer surface of the wall of the stove hole, the outer wall of the lifting ring 4 is sealed with the panel 1, and the inner cavity of the lifting ring 4 communicates with the gas collection box 5, and is exposed when the lifting ring 4 is raised. The inner part of the lifting ring 4 of the wall of the stove hole is provided with an air suction port 8, and the lifting ring 4 is connected with a lifting drive mechanism.

[0030] The lifting drive mechanism includes: a horizontally movable pull rod...

Embodiment 2

[0042] The difference between this embodiment and the first embodiment lies in the connection method between the lifting ring and the pull rod. In this embodiment, the lifting ring 4 has a chute 10, and the pin 11 connected to the pull rod 9 is set in the chute 10. Inside. All the other are the same as the first embodiment.

Embodiment 3

[0044] The difference between the present embodiment and the first embodiment lies in the lifting drive mechanism, the drive mechanism of the present embodiment is a rack 19, the rack 19 meshes with a gear, and the gear is driven by a motor.

[0045] All the other are the same as the first embodiment.

[0046] When the suction port is to be closed, the rack 19 pulls the lifting ring 4 to slide down along the wall of the stove hole until the suction port 8 on the lifting ring 4 is covered by the wall of the stove hole.

[0047] When the suction port needs to be opened, the rack 19 pulls the lifting ring 4 to slide upwards along the wall of the stove hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com