OTP construction and manufacturing method thereof

A technology of silicon oxide layer and silicon oxide, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems that the OTP structure cannot meet the high-density storage function, and achieve area saving, production cost reduction, and improved The Effect of Storage Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

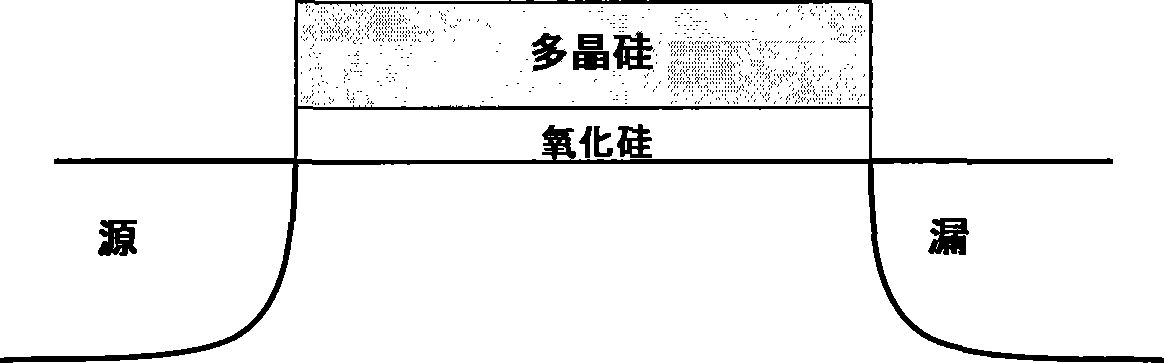

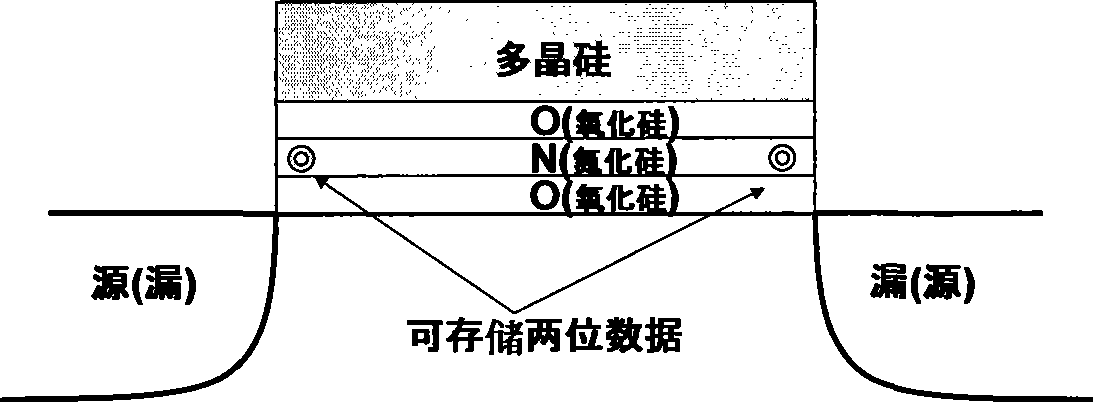

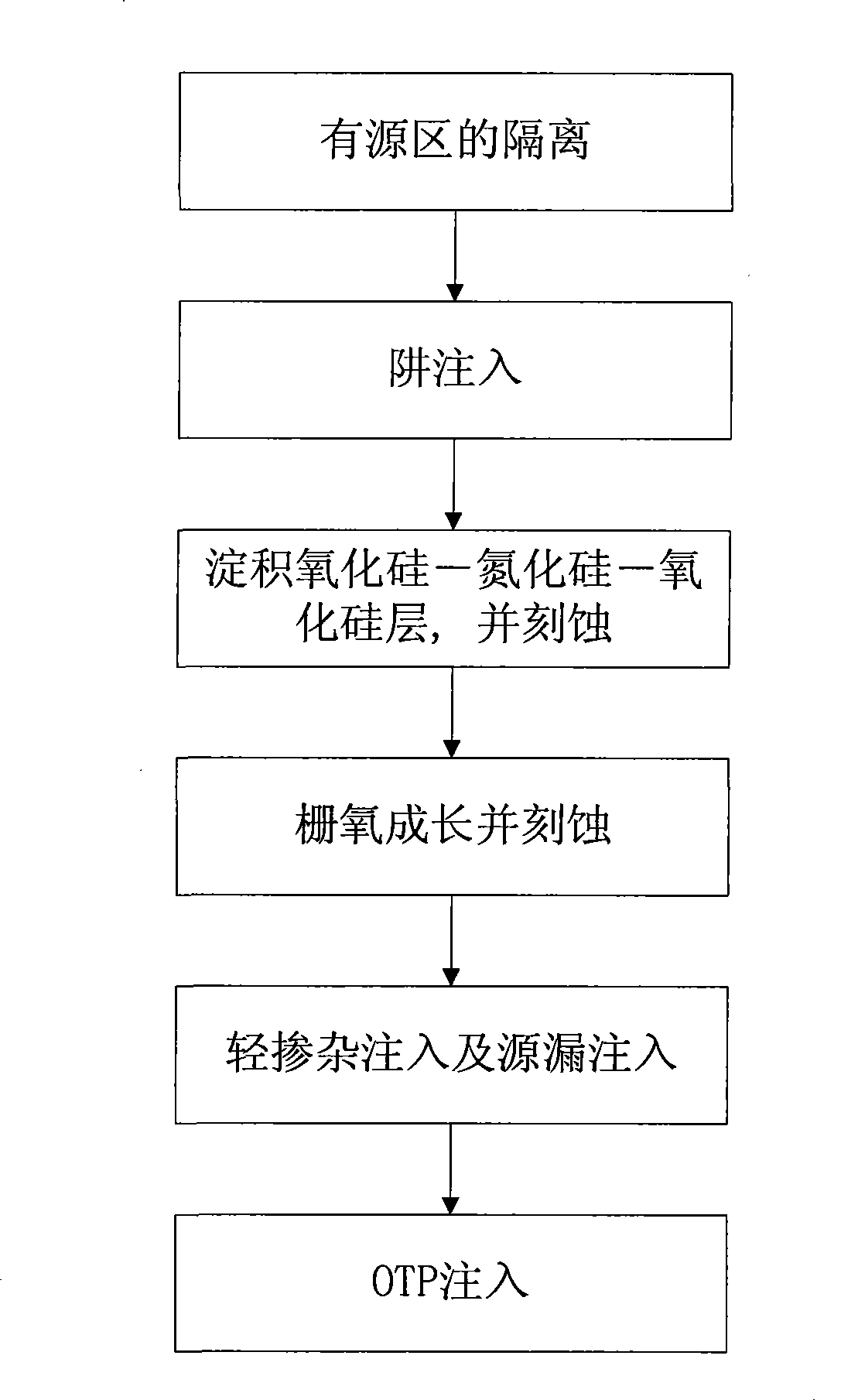

[0015] Such as figure 1 As shown, the OTP structure of the present invention includes a substrate, and the top of the substrate is successively silicon oxide-silicon nitride-silicon oxide layer and polysilicon layer, and the two sides of the polysilicon on the substrate are respectively a source electrode and a drain electrode, wherein silicon oxide-silicon oxide layer The thickness of the silicon oxide layer on both sides of the silicon nitride-silicon oxide layer is greater than 50 Angstroms.

[0016] When writing data to the OTP structure of the present invention, electrons will be trapped in the nitride layer of silicon oxide-silicon nitride-silicon oxide layer and not easy to move. When the potential is high, hot electron injection occurs on the side near the drain end, and write electrons are stored on the side of the silicon oxide-silicon nitride-silicon oxide layer. When a high potential is applied to the source terminal and a low potential is applied to the drain, ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com