Heating plate of flat-plate vulcanizing machine

A technology of flat vulcanizer and heating plate, applied in the field of machinery, can solve the problems of difficult to control temperature uniformity, large and complex heating source of vulcanizer, etc., and achieve the effect of uniform heating and rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

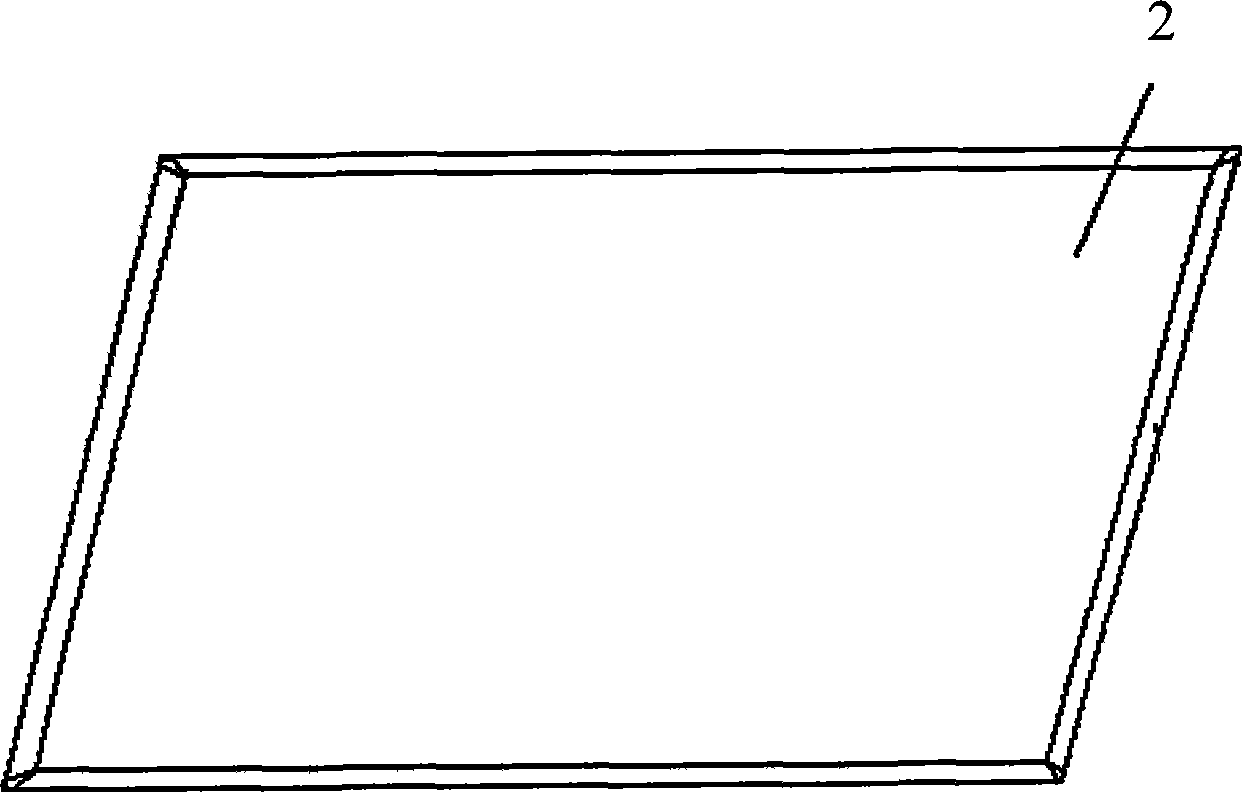

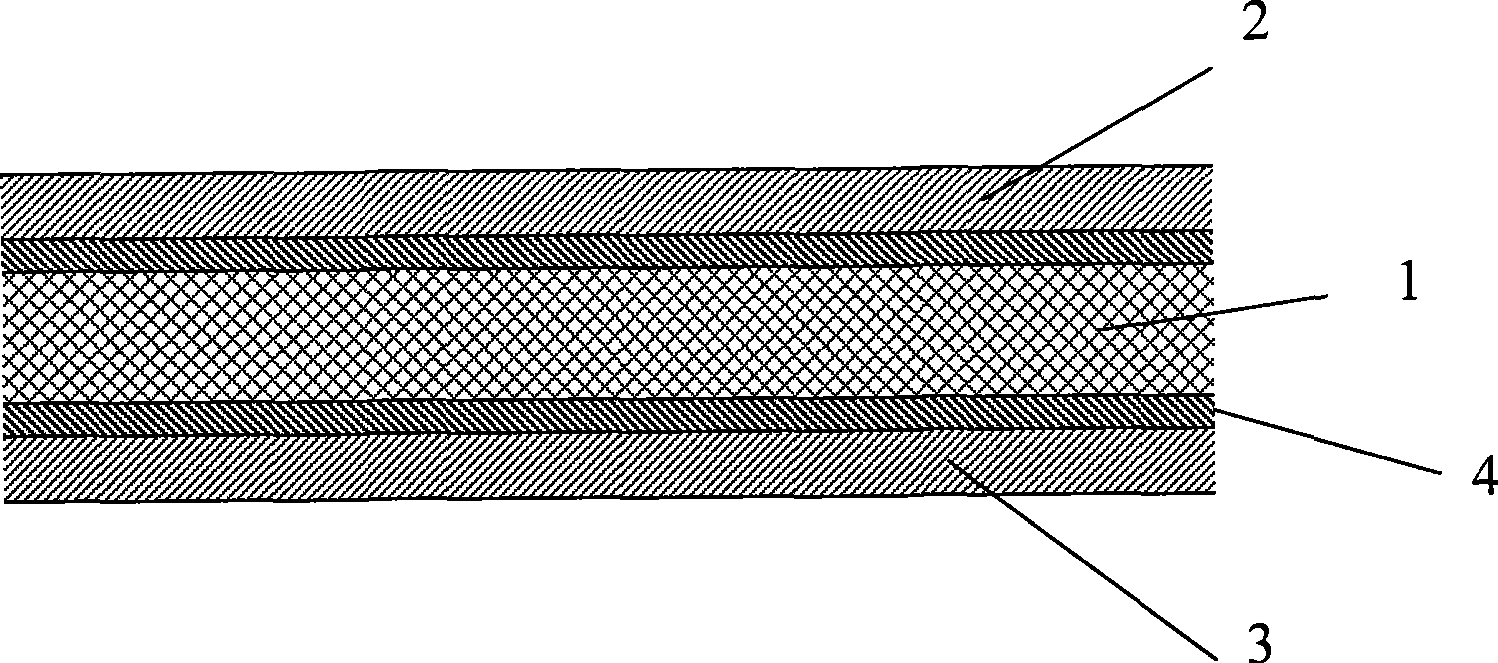

[0012] Such as figure 1 with figure 2 As shown, the heating plate of the flat vulcanizing machine of the present invention is composed of a layer of electric heating film 1, wherein, the upper side of the electric heating film 1 is provided with a layer of upper heat conducting plate 2, and the lower side of the electric heating film 1 is provided with There is a lower heat conduction plate 3, an insulating layer 4 is arranged between the electric heating film 1 and the upper heat conduction plate 2, and between the electric heating film 1 and the lower heat conduction plate 3, and the edge of the lower heat conduction plate 3 exceeds The edge of the electric heating film 1 is folded upwards and surrounds the edge of the upper heat conducting plate 2 . The upper heat conduction plate 2 and the lower heat conduction plate 2 are respectively made of copper alloy material, and the insulating layer is made of mica material.

[0013] Further, the copper alloy material contains c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com