Liquid sulfur pool high temperature resistant and corrosion proof structure and construction method thereof

A liquid sulfur, high temperature resistant technology, used in gymnasiums, swimming pools, building components, etc., to achieve the effect of small thermal conductivity, reduced maintenance and repair costs, and excellent thermal insulation and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

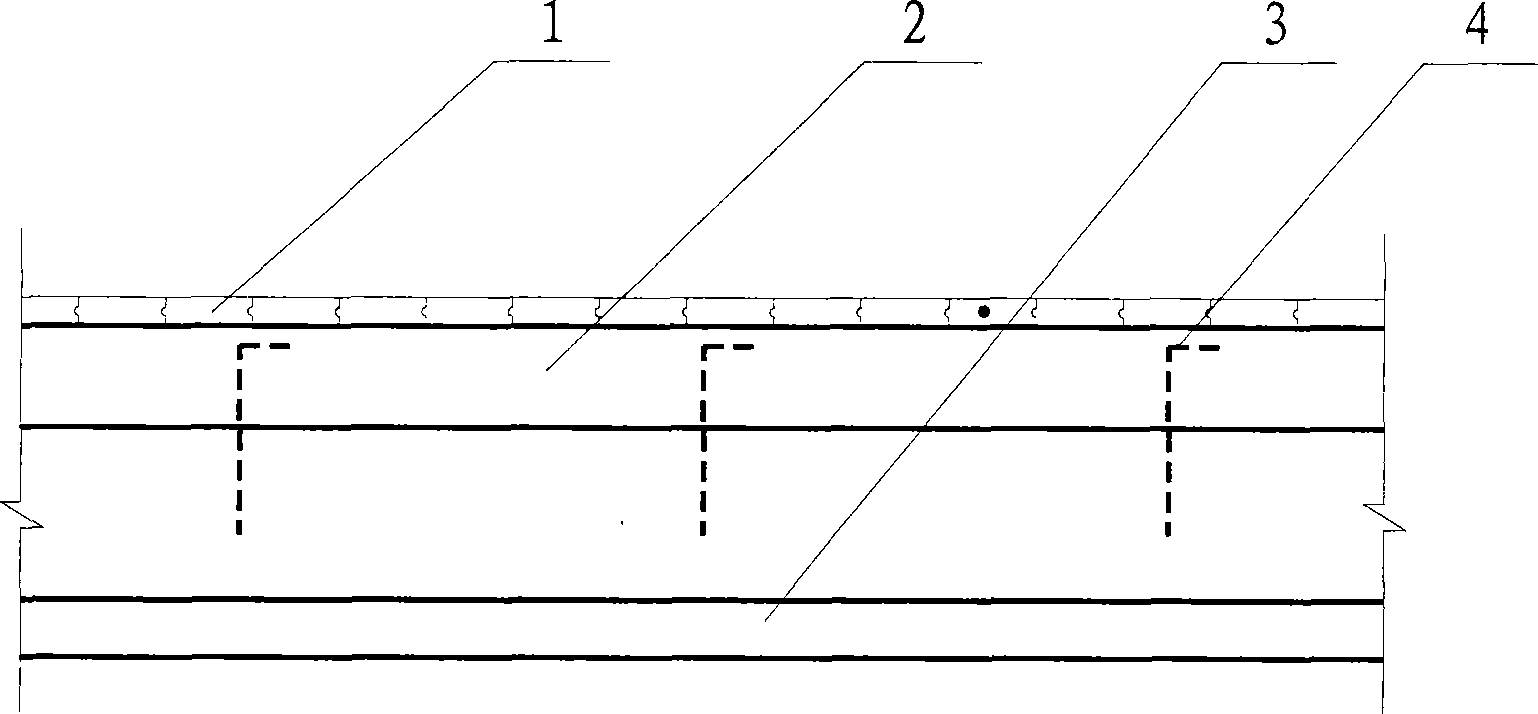

[0032] 1. High temperature resistant and anti-corrosion structure on the bottom of the liquid sulfur pool

[0033] Such as figure 1 As shown, the high-temperature resistant and anti-corrosion structure on the bottom of the liquid sulfur pool is composed of a sulfur pool bottom plate 3, a thermal insulation pouring layer 2, and an alumina tile layer 3 from bottom to top. Reserved anchors4.

[0034] The physical and chemical properties of the thermal insulation pouring layer 2 are as follows:

[0035] Bulk density, 110℃×24h ≥2.3g / cm 2

[0036] Compressive strength, 110℃×24h ≥50Mpa

[0037] Linear change after high temperature firing, 8150℃×3h -0.2~0.

[0038] The thermal insulation pouring layer is made of thermal insulation pouring material, and the thermal insulation casting material is a product named high temperature aluminum refractory castable produced by Zibo Huaqing Refractory Material Co., Ltd.

[0039] The alumina tile layer 3 is made of alumina tiles, and the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com