Reactor suitable for sulphur dioxide gas leach manganese dioxide ore

A sulfur dioxide and reactor technology, applied in manganese sulfate and other directions, can solve problems such as affecting the absorption rate of sulfur dioxide, restricting industrial application and promotion, affecting the speed of chemical reaction, etc. Manganese disulfate is generated, and the effect of continuous leaching and discharge is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

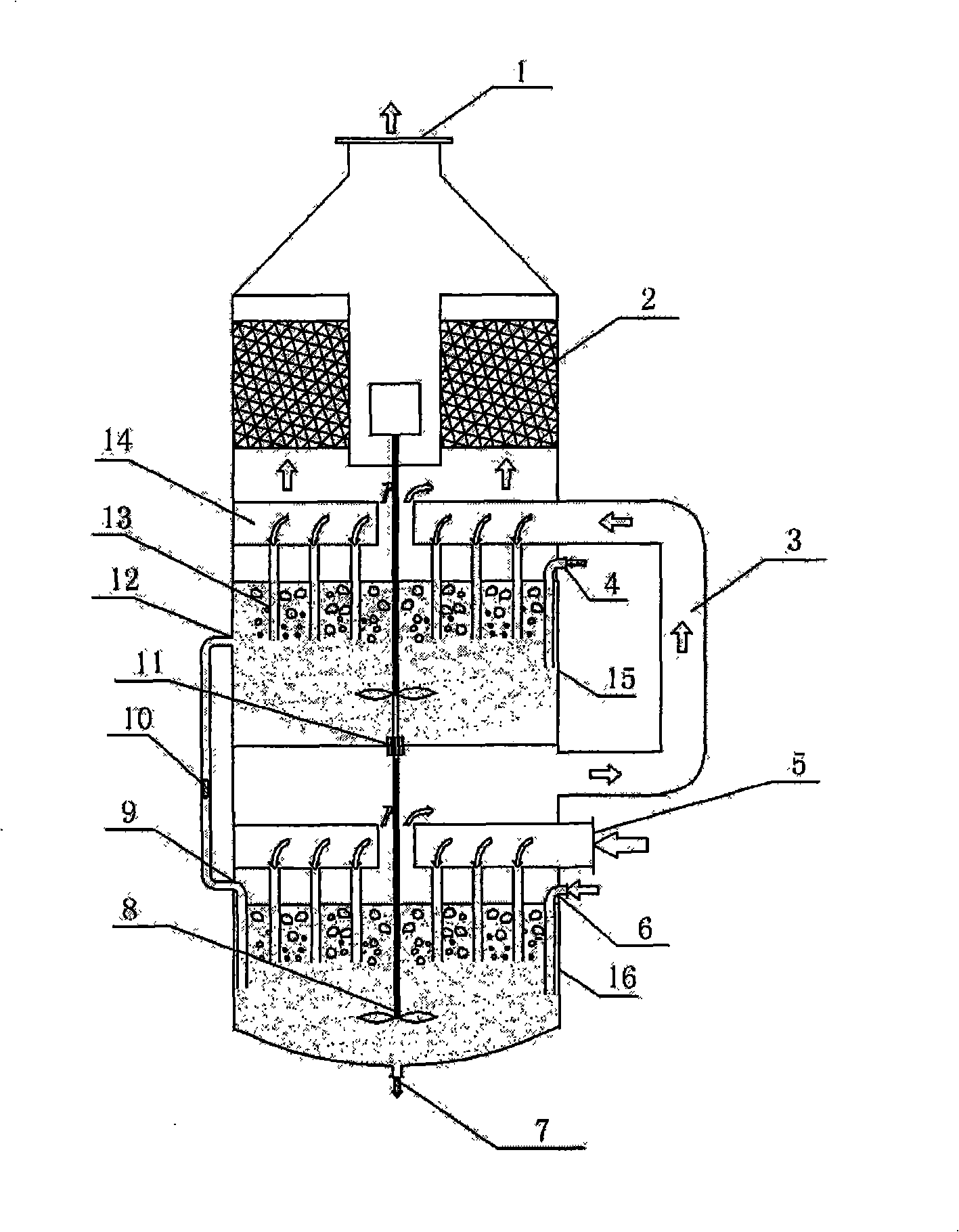

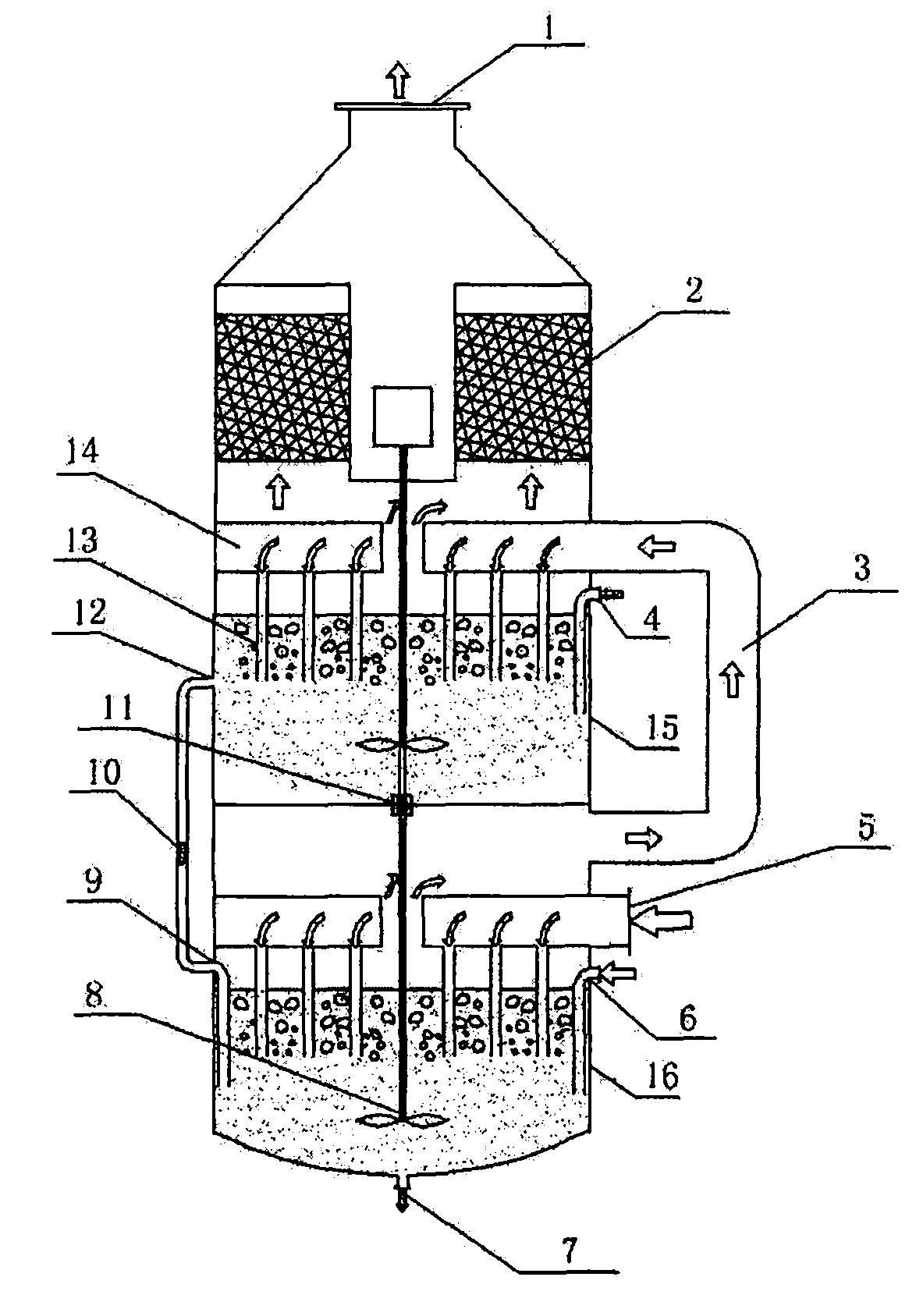

[0025]The structure of the reactor suitable for leaching pyrolusite with sulfur dioxide gas in this embodiment is shown in the accompanying drawings. The reactor cylinder is provided with a first-level absorption and leaching reaction chamber 15 and a second-level absorption and leaching reaction chamber 16 connected in series up and down. The second-level absorption and leaching reaction chamber is located below the first-level absorption and leaching reaction chamber. Each reaction chamber is equipped with a stirrer. 8. The upper part is equipped with a sulfur dioxide reaction gas intake gas distribution chamber 14 and an exhaust gas accumulation chamber. Below the intake gas distribution chamber, there are several injection pipes 13 inserted into the reaction slurry. The lower end of the injection pipe is processed with a spray pipe The upper end communicates with the inlet air distribution chamber, and an exhaust gas demister communicated with the gas accumulation chamber i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com