High-pressure high flow fatigue test system for bearing equipment

A fatigue test and pressure-bearing equipment technology, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, can solve the problems that it is difficult to meet the fatigue test requirements of large-volume high-pressure vessels, the output flow is small, and the output pressure is low. Low noise, stable pressure and high output pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail with reference to the above-mentioned drawings.

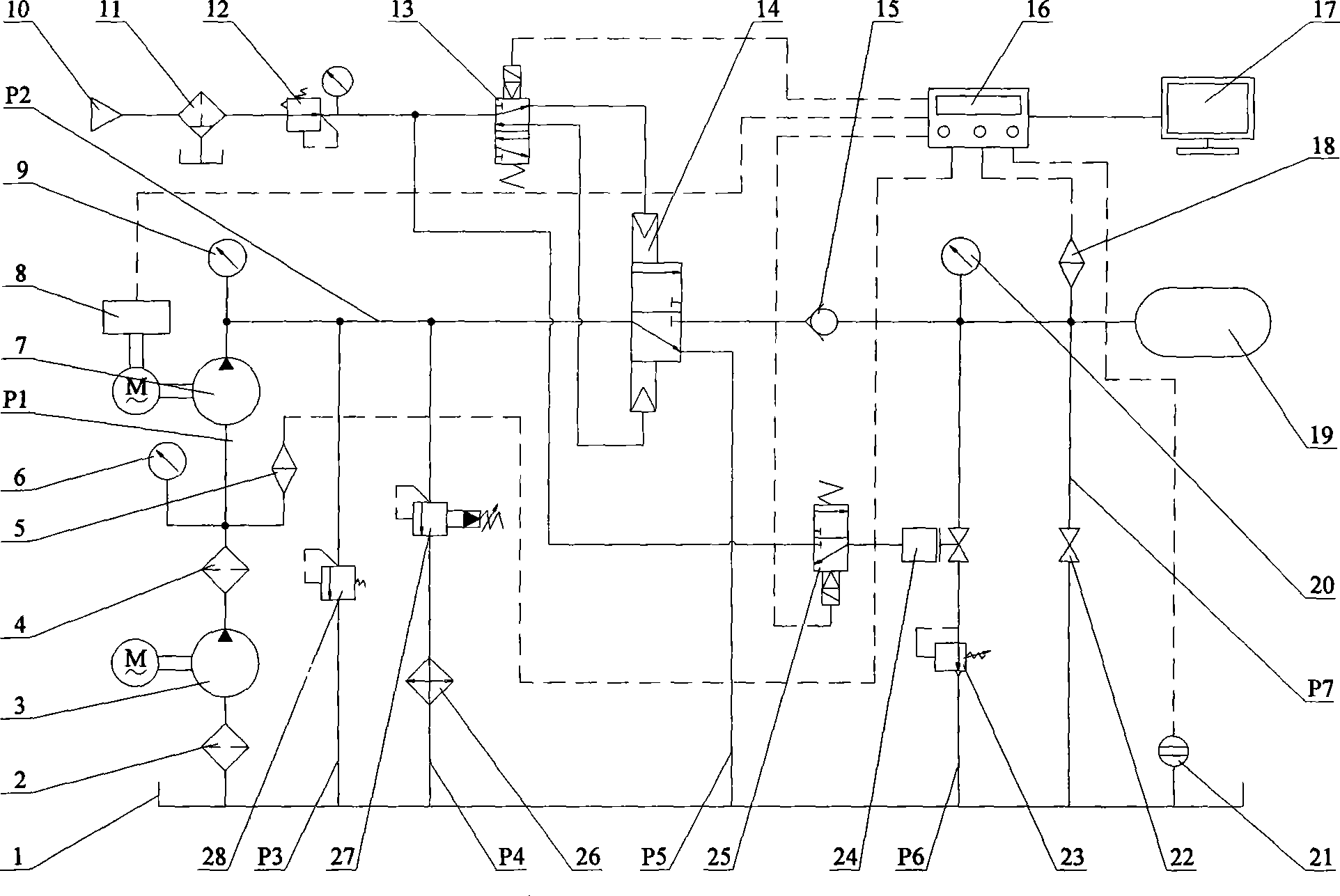

[0016] like figure 1 As shown, a high-pressure and large-flow fatigue test system for pressure-bearing equipment includes a low-pressure liquid supply device, a pressure lifting device, a gas drive device and a measurement control system. The low-pressure liquid supply device is connected by a low-pressure liquid inlet pipeline P1. 2, a motor-driven low-pressure pump 3, and a high-precision filter 4; the pressure lifting device is composed of a motor-driven high-pressure and large-flow booster pump 7, a safety valve 28, an overflow valve 27, a cooler 26, an air control valve 14, It is composed of high pressure single valve 15, pneumatic pressure relief valve 24, back pressure valve 23 and manual pressure relief valve 22. Motor driven high pressure and large flow booster pump 7, air control valve 14 and high pressure single valve 15 are located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com